-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

3 die thread rolling machine service

The Importance of 3% Die Thread Rolling Machine Service

Thread rolling is a critical manufacturing process that involves forming external threads on cylindrical metal workpieces. This technique has garnered significant attention across various industries, including automotive, aerospace, and construction, due to its ability to enhance the strength and durability of threaded components. Among the various machines employed in thread rolling, the die thread rolling machine is indispensable. However, to maintain optimal performance and extend the lifespan of these machines, regular servicing is crucial. This article emphasizes the importance of 3% die thread rolling machine service and its impact on production efficiency.

Understanding the Die Thread Rolling Machine

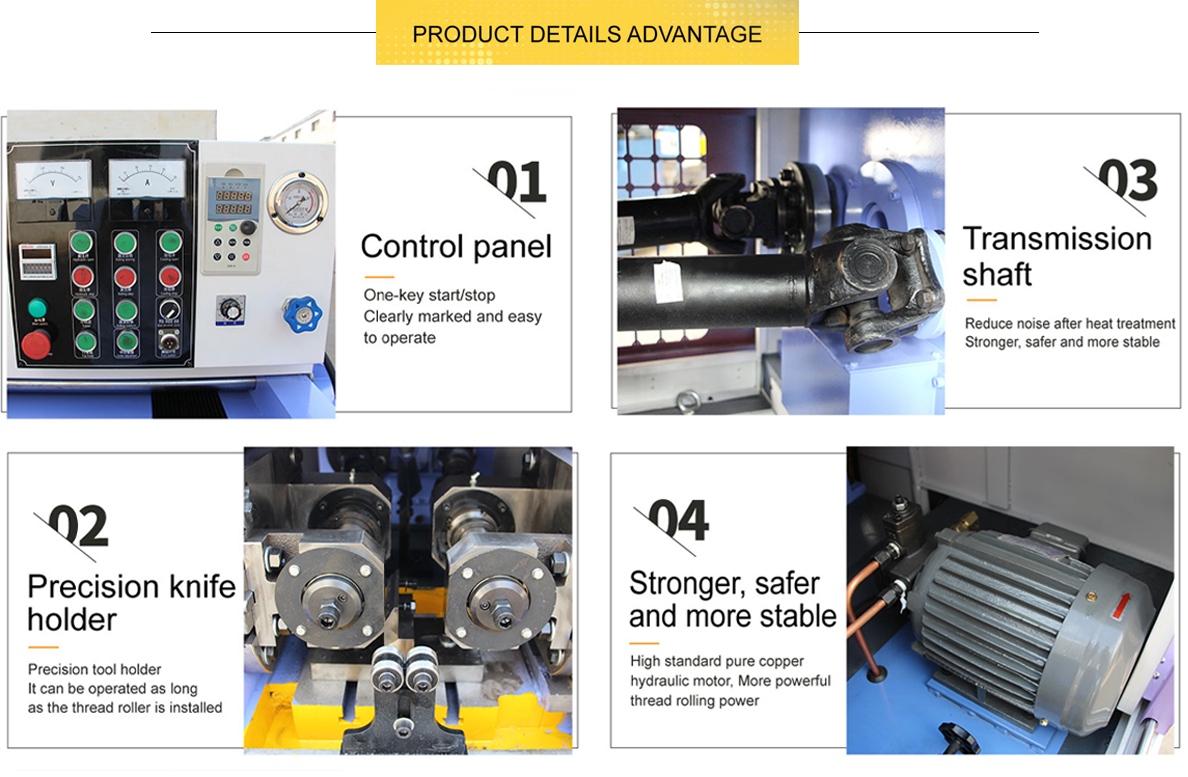

A die thread rolling machine uses two cylindrical dies to impart threads onto a blank workpiece through a process known as cold forming. Compared to traditional threaded cutting methods, thread rolling offers several advantages, including reduced production time, improved material utilization, and enhanced mechanical properties. These machines are widely utilized in producing fasteners, bolts, and various threaded components essential in manufacturing sectors.

The Need for Regular Service

Despite their robustness, die thread rolling machines require regular maintenance to ensure they operate at peak performance. Over time, wear and tear can affect the machine's ability to produce high-quality threads. A well-maintained machine not only improves the accuracy and consistency of the threading process but also minimizes the risk of production halts caused by equipment failure.

One critical maintenance aspect is inspecting the dies for wear. The dies are subjected to immense pressure and friction during the rolling process, leading to eventual degradation. A 3% service maintenance strategy entails scheduling preventive maintenance every time the dies are expected to wear down by this percentage. This proactive approach aids in identifying issues before they escalate into significant problems, thereby avoiding costly downtime.

Benefits of a 3% Maintenance Strategy

3 die thread rolling machine service

Implementing a 3% service strategy for die thread rolling machines comes with several advantages

1. Enhanced Machine Longevity By adhering to a regular maintenance schedule, businesses can significantly extend the lifespan of their thread rolling machines. Addressing wear and tear early on ensures that the machines remain in optimal working condition, delaying the need for costly replacements.

2. Improved Product Quality Regular servicing allows for the consistent production of high-quality threaded components. Any misalignment or wear in the dies can lead to inconsistencies in the thread profile, impacting product performance. With routine maintenance, the precision of the threading process is maintained, resulting in better-quality end products.

3. Increased Production Efficiency Well-maintained machines operate more efficiently, thus minimizing energy consumption and reducing production costs. The reduction in unexpected machine failures contributes to more predictable manufacturing schedules, which is crucial in meeting client deadlines.

4. Safety Considerations A neglected machine can pose safety risks to operators, especially if mechanical failures occur during operation. Regular servicing ensures that all safety mechanisms are functional and that the machine operates within its designed parameters.

5. Cost Savings Though maintenance may seem like an added expense, failing to service machines can lead to prolonged downtimes and expensive repairs. A 3% maintenance schedule allows companies to budget for regular maintenance, leading to better financial planning and avoiding the larger costs associated with emergency repairs.

Conclusion

The role of a die thread rolling machine is critical in ensuring the production of reliable threaded components across various industries. Adopting a 3% service maintenance strategy provides numerous benefits, including enhanced machine longevity, improved product quality, and increased production efficiency. In today’s competitive manufacturing landscape, it is vital for organizations to prioritize regular maintenance for their machinery, not only to uphold operational standards but also to safeguard their financial investments. By focusing on preventative care through scheduled servicing, companies can ensure that their die thread rolling machines remain a vital part of their manufacturing capabilities.