-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

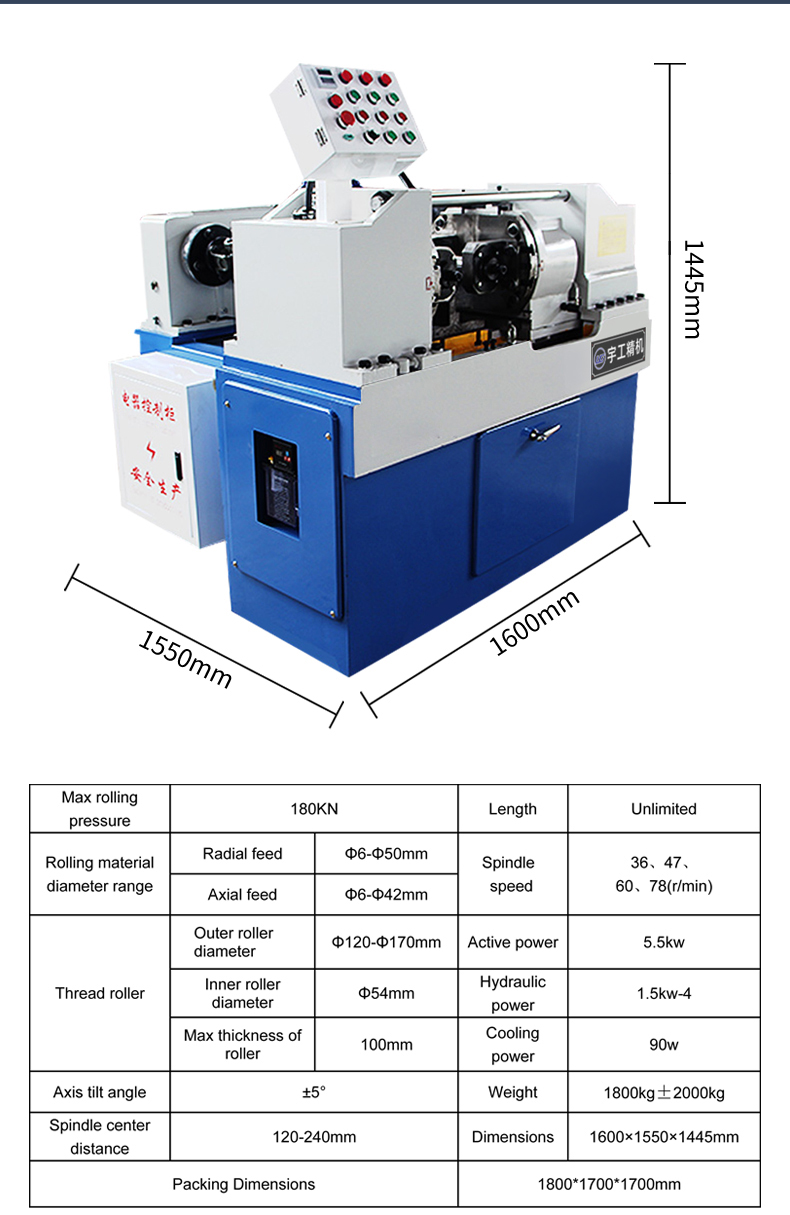

A Comprehensive Guide to Nail Thread Rolling Machine Prices and Specifications

Overview of Nail Thread Rolling Machine Price Lists

In today's competitive manufacturing landscape, the efficiency and quality of production processes are crucial to success. Among various tools and machinery that aid in production, the nail thread rolling machine has emerged as an essential asset, particularly for industries focused on fasteners. Understanding the price lists for these machines is vital for businesses aiming to invest or upgrade their manufacturing capabilities.

Understanding Nail Thread Rolling Machines

Nail thread rolling machines are specialized equipment used to create threads on nails and other fasteners. These machines use a process called rolling, which involves deforming a piece of metal to create the desired thread profile rather than cutting it. This method not only enhances the strength of the threads but also improves the overall surface finish of the final product. As a result, manufacturers are increasingly opting for thread rolling machines over traditional cutting methods.

Factors Influencing Pricing

The price of nail thread rolling machines can vary significantly based on several factors

. Here are some of the primary elements that contribute to the cost1. Machine Type and Specifications Different thread rolling machines come with various configurations and capabilities. For example, some machines are designed for high-volume production, while others are intended for smaller batches. Machines with advanced features like programmable controls, automation, and higher production speeds typically command higher prices.

2. Manufacturing Technology The technology employed in the machine also affects pricing. Hydraulic and mechanical machines have different cost structures, with hydraulic machines generally priced higher due to their enhanced performance and energy efficiency. Additionally, modern CNC (Computer Numerical Control) models offer greater precision and repeatability but also come with a higher price tag.

nail thread rolling machine pricelist

3. Brand and Vendor Reputation Established brands with a history of reliability and performance often charge a premium for their machines. Investing in a reputable brand can sometimes lead to lower long-term costs, as these machines may require less maintenance and provide greater durability.

4. Customization and Additional Features Many manufacturers offer customization options for their machines, which can increase the price. Features such as enhanced safety systems, data logging capabilities, and quick change tooling can all contribute to a higher overall cost.

5. Geographical Factors The cost of nail thread rolling machines can vary by region due to shipping costs, tariffs, and local market conditions. Import duties can significantly affect the final price for machines shipped internationally.

Average Price Range

While prices can vary widely, entry-level nail thread rolling machines might start at around $10,000, while more advanced models can exceed $100,000. This broad range reflects the diverse needs of manufacturers, from smaller operations looking for basic thread rolling capabilities to large facilities requiring heavy-duty machines capable of high-speed production.

Conclusion

Investing in a nail thread rolling machine is a significant decision for any manufacturing business, requiring careful consideration of various factors that influence pricing. Understanding the market landscape and specific requirements of your operation will help ensure that you choose the right machine for your needs. By evaluating the different types of machines available, their features, and their associated costs, businesses can better position themselves for success in the competitive landscape of fastener production. Ultimately, the right machine can enhance production efficiency, improve product quality, and drive profitability.