-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

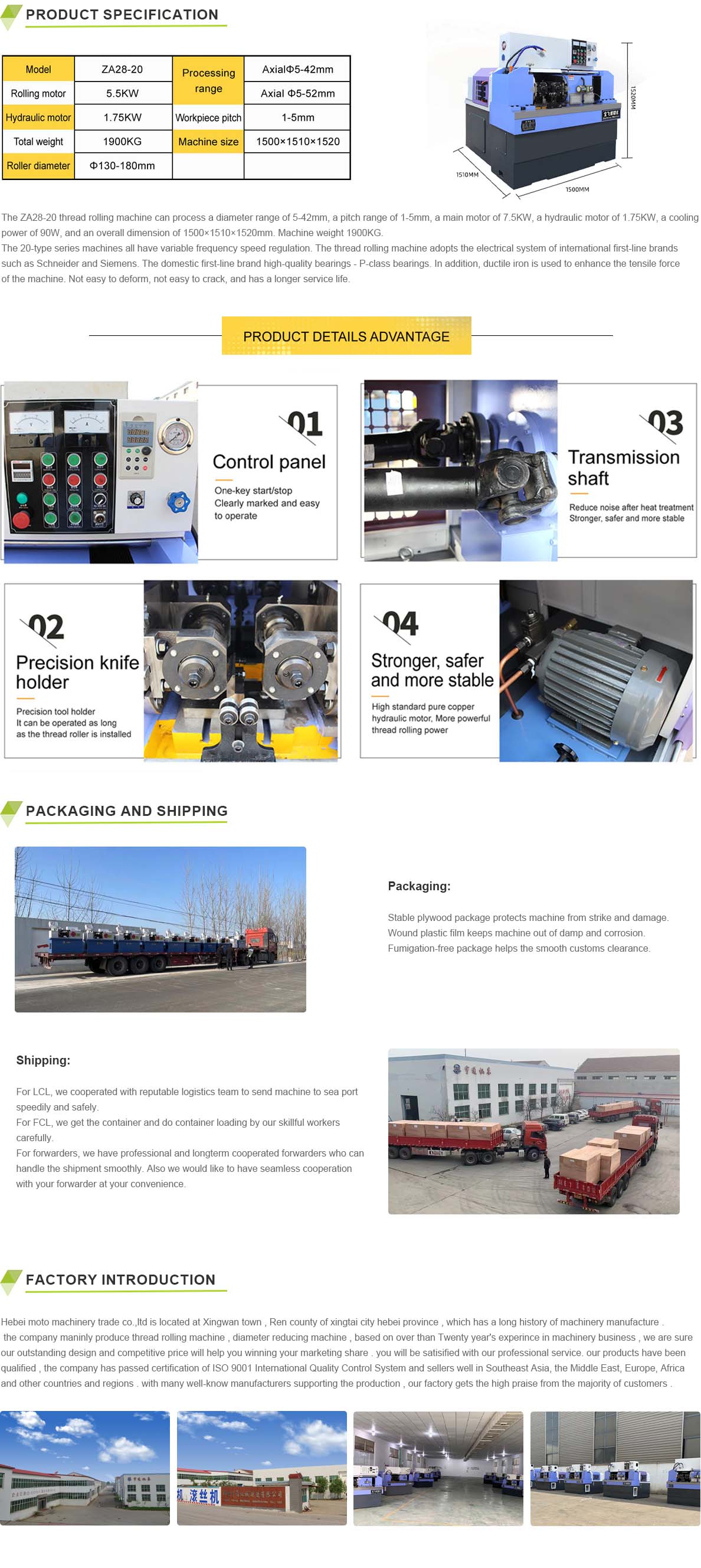

Advanced Die Thread Rolling Machines for Precision Production and Enhanced Efficiency in Manufacturing Processes

Understanding the ODM 203 Die Thread Rolling Machine

The ODM 203 Die Thread Rolling Machine represents a significant advancement in manufacturing technology, particularly in the field of metalworking. As industries increasingly seek efficiency, precision, and the ability to produce high-quality threaded components, machines like the ODM 203 have become indispensable.

What is a Die Thread Rolling Machine?

A die thread rolling machine is a specialized piece of equipment designed to create threads on metal rods or bars through a process known as thread rolling. Unlike traditional cutting methods that remove material to form threads, thread rolling is a cold deformation process that displaces the material to create threads. This means that the threads retain the integrity of the base material, providing superior strength and durability.

The ODM 203 model specifically caters to a range of applications, including but not limited to automotive, aerospace, and general manufacturing industries. Its versatility makes it a popular choice for companies looking to produce various thread sizes and configurations efficiently.

Key Features of the ODM 203

One of the standout features of the ODM 203 Die Thread Rolling Machine is its design that prioritizes both ease of use and precision. The machine is equipped with user-friendly controls that allow operators to set parameters quickly, enabling rapid changeovers between different thread specifications.

Moreover, the ODM 203 utilizes high-quality die sets, ensuring consistency in thread quality while minimizing the risk of defects

. These die sets can be easily replaced or adjusted, allowing for flexibility in production runs, whether for small batches or large-scale manufacturing.Another critical feature is its robust construction, which ensures durability under intensive use. The machine is built to withstand the rigors of continuous operation, ensuring longevity and a high return on investment. Additionally, its compact design allows for efficient use of space in manufacturing environments, making it suitable for both small workshops and large factories.

odm 3 die thread rolling machine

Advantages of Thread Rolling

The advantages of using a die thread rolling machine like the ODM 203 extend beyond the immediate production benefits. Thread rolling itself offers several advantages over traditional cutting methods. For one, it produces stronger threads due to the work-hardening effect of the material, which increases fatigue resistance.

Furthermore, thread rolling generally leads to a smoother finish, reducing the need for secondary operations such as polishing or cleaning. This not only saves time but also minimizes waste, making the overall process more environmentally friendly.

Applications in Various Industries

The ODM 203 Die Thread Rolling Machine is widely applicable across numerous industries. In the automotive sector, it is used to produce bolts and screws that must withstand high stress and vibration. The aerospace industry relies on the precision and reliability of threaded components for critical applications, where failure is not an option.

In addition, the ODM 203 is utilized in the manufacturing of construction hardware, machinery parts, and other applications where high strength and precision are paramount. Its flexibility allows manufacturers to respond swiftly to changing market demands, producing custom-threaded components without significant downtime.

Conclusion

In conclusion, the ODM 203 Die Thread Rolling Machine is a remarkable tool that embodies the future of thread manufacturing. Its combination of precision, efficiency, and durability makes it a vital asset in today’s competitive manufacturing landscape. As industries continue to evolve, machines like the ODM 203 will play a crucial role in meeting the growing demands for high-quality threaded products across various sectors.