-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 26, 2024 20:00

Back to list

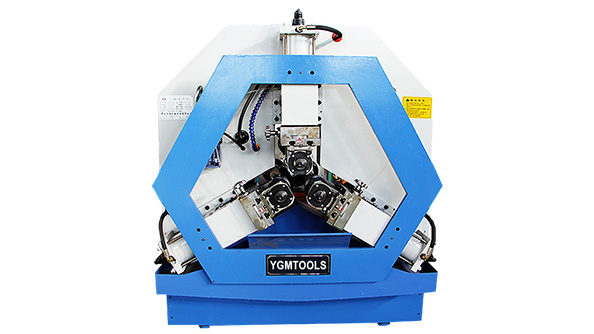

Advanced Thread Rolling Machine Manufacturing Expert Factory Production

The Pivotal Role of Thread Rolling Machines in Modern Factory Operations

In the heart of modern manufacturing lies the thread rolling machine factory, a hub of precision engineering and industrial prowess. These factories specialize in the production of thread rolling machines, an essential tool in various industries, particularly in the production of high-strength, precise threads for bolts, screws, and other fasteners.

Thread rolling machines, unlike conventional cutting methods, shape the material by applying compressive forces, resulting in stronger threads with superior fatigue resistance. They operate on a principle that combines the science of metallurgy with the art of machining, creating threads that are not only dimensionally accurate but also have a smoother surface finish.

The factory floor is a testament to the seamless integration of technology and human expertise. State-of-the-art machinery, often computer-controlled, stands tall amidst the rhythmic hum of activity. Each machine is designed to handle different materials and thread sizes, ensuring versatility in production. Engineers and technicians work in tandem, overseeing the process from design conception to final product testing, ensuring every machine meets stringent quality standards.

The production process begins with raw materials, typically steel or alloy, which are fed into the machine. The thread rolling process follows, where three dies, precisely engineered to match the desired thread profile, press against the material, shaping it without removing any. This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time

This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time thread rolling machine factory.

Quality control is a key aspect in a thread rolling machine factory. Every machine undergoes rigorous testing before it leaves the factory, ensuring its performance and durability meet customer expectations. Advanced inspection equipment, such as coordinate measuring machines, are utilized to verify dimensional accuracy and thread conformity.

Moreover, these factories are not just centers of production; they are also incubators of innovation. With constant advancements in technology, the factories invest heavily in research and development to enhance machine efficiency, reduce energy consumption, and improve overall productivity. The pursuit of excellence drives them to explore new materials, designs, and techniques, pushing the boundaries of what thread rolling machines can achieve.

In conclusion, a thread rolling machine factory is a microcosm of industrial progress, where traditional craftsmanship meets cutting-edge technology. It is a place where metal is transformed into precision-engineered tools that hold together the world's infrastructure, from towering skyscrapers to intricate machinery. These factories not only manufacture machines but also contribute significantly to the global manufacturing landscape, fostering economic growth and technological advancement.

thread rolling machine factory.

Quality control is a key aspect in a thread rolling machine factory. Every machine undergoes rigorous testing before it leaves the factory, ensuring its performance and durability meet customer expectations. Advanced inspection equipment, such as coordinate measuring machines, are utilized to verify dimensional accuracy and thread conformity.

Moreover, these factories are not just centers of production; they are also incubators of innovation. With constant advancements in technology, the factories invest heavily in research and development to enhance machine efficiency, reduce energy consumption, and improve overall productivity. The pursuit of excellence drives them to explore new materials, designs, and techniques, pushing the boundaries of what thread rolling machines can achieve.

In conclusion, a thread rolling machine factory is a microcosm of industrial progress, where traditional craftsmanship meets cutting-edge technology. It is a place where metal is transformed into precision-engineered tools that hold together the world's infrastructure, from towering skyscrapers to intricate machinery. These factories not only manufacture machines but also contribute significantly to the global manufacturing landscape, fostering economic growth and technological advancement.

This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time

This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time This cold-forming process not only enhances the mechanical properties of the material but also reduces waste and production time thread rolling machine factory.

Quality control is a key aspect in a thread rolling machine factory. Every machine undergoes rigorous testing before it leaves the factory, ensuring its performance and durability meet customer expectations. Advanced inspection equipment, such as coordinate measuring machines, are utilized to verify dimensional accuracy and thread conformity.

Moreover, these factories are not just centers of production; they are also incubators of innovation. With constant advancements in technology, the factories invest heavily in research and development to enhance machine efficiency, reduce energy consumption, and improve overall productivity. The pursuit of excellence drives them to explore new materials, designs, and techniques, pushing the boundaries of what thread rolling machines can achieve.

In conclusion, a thread rolling machine factory is a microcosm of industrial progress, where traditional craftsmanship meets cutting-edge technology. It is a place where metal is transformed into precision-engineered tools that hold together the world's infrastructure, from towering skyscrapers to intricate machinery. These factories not only manufacture machines but also contribute significantly to the global manufacturing landscape, fostering economic growth and technological advancement.

thread rolling machine factory.

Quality control is a key aspect in a thread rolling machine factory. Every machine undergoes rigorous testing before it leaves the factory, ensuring its performance and durability meet customer expectations. Advanced inspection equipment, such as coordinate measuring machines, are utilized to verify dimensional accuracy and thread conformity.

Moreover, these factories are not just centers of production; they are also incubators of innovation. With constant advancements in technology, the factories invest heavily in research and development to enhance machine efficiency, reduce energy consumption, and improve overall productivity. The pursuit of excellence drives them to explore new materials, designs, and techniques, pushing the boundaries of what thread rolling machines can achieve.

In conclusion, a thread rolling machine factory is a microcosm of industrial progress, where traditional craftsmanship meets cutting-edge technology. It is a place where metal is transformed into precision-engineered tools that hold together the world's infrastructure, from towering skyscrapers to intricate machinery. These factories not only manufacture machines but also contribute significantly to the global manufacturing landscape, fostering economic growth and technological advancement. Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025