-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Affordable Hydraulic Thread Rolling Machine Prices from Leading Manufacturers for Optimal Performance

Understanding the Price and Manufacturers of Hydraulic Thread Rolling Machines

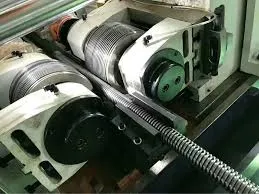

Hydraulic thread rolling machines are essential tools in various manufacturing processes, particularly in industries such as automotive, aerospace, and construction. These machines are designed to create threads on cylindrical materials using a rolling process, which is both efficient and effective. As industries continue to grow and evolve, the demand for high-quality hydraulic thread rolling machines has increased, leading to a competitive market filled with various manufacturers and price ranges.

What is a Hydraulic Thread Rolling Machine?

A hydraulic thread rolling machine uses hydraulic pressure to roll the material between two hardened dies that are shaped like the desired thread profile. The process involves feeding a workpiece into the machine, where it is then deformed to create threads. This method of threading offers several advantages over traditional cutting methods, such as reduced waste, increased strength of the threads, and enhanced surface finish.

Factors Affecting the Price of Hydraulic Thread Rolling Machines

The price of hydraulic thread rolling machines can vary significantly based on several factors

1. Machine Specifications The size, capacity, and operational features of the machine play a significant role in pricing. Larger machines capable of handling more substantial materials or higher production volumes typically cost more.

2. Technology and Features Modern machines equipped with advanced technologies, such as programmable controls, automated feeding systems, and enhanced safety features, are generally priced higher due to their increased efficiency and ease of use.

3. Brand and Manufacturer Reputation Established manufacturers often command higher prices due to their reputation for quality, reliability, and customer service. On the other hand, newer or lesser-known brands may offer competitive pricing to penetrate the market.

4. Customizations Many manufacturers offer customizable options tailored to specific production needs. These custom solutions can significantly impact the overall price.

5. Material Quality The quality of materials used in manufacturing the machine can also affect the price. Higher quality materials lead to better durability and longer operational life.

hydraulic thread rolling machine price manufacturer

Market Overview and Leading Manufacturers

The market for hydraulic thread rolling machines is characterized by a diverse range of manufacturers. Some of the leading companies in this field include

- Schneider Known for its innovative designs and high-quality standards, Schneider offers a variety of hydraulic thread rolling machines that cater to different industry needs.

- Acme Manufacturing Company Acme is recognized for its advanced technology in the production of thread rolling machines, providing solutions that enhance productivity and accuracy.

- Screw Machine Products This manufacturer focuses on producing versatile machines that can be used for various threading applications, making them a popular choice among manufacturers.

- Morris Great Lakes Offering a robust lineup of hydraulic thread rolling machines, Morris is a trusted name in the industry, known for its reliable customer support.

Price Range

The price of hydraulic thread rolling machines can range from a few thousand to tens of thousands of dollars, depending on the specifications and features mentioned earlier. A basic model may start around $5,000, while high-end, fully automated machines could exceed $50,000. It is essential for businesses to evaluate their production needs carefully to choose a machine that offers the best value for money.

Conclusion

In conclusion, hydraulic thread rolling machines are vital assets in the manufacturing process, providing efficient and strong threaded solutions. The price of these machines varies based on several factors, including specifications, technology, and manufacturer reputation. As businesses look to invest in these machines, understanding the market and choosing the right manufacturer can lead to informed purchasing decisions that optimize production efficiency and cost-effectiveness. Whether a small workshop or a large manufacturing facility, selecting the appropriate hydraulic thread rolling machine is a step towards enhanced operational capabilities.