-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Affordable Prices for High-Quality Hydraulic Thread Rolling Machines Available for Purchase Online

The Price of High-Quality Hydraulic Thread Rolling Machines A Comprehensive Overview

In today’s manufacturing landscape, the demand for precision-engineered products has never been higher. One of the critical processes that contributes to this demand is thread rolling, particularly using hydraulic thread rolling machines. These machines are renowned for their ability to produce high-quality threads with exceptional accuracy and efficiency. However, understanding the pricing of such machines is crucial for manufacturers aiming to invest in the best technology to enhance productivity.

What is a Hydraulic Thread Rolling Machine?

A hydraulic thread rolling machine is a robust piece of equipment used to create threads on cylindrical workpieces. Unlike traditional machining processes, which involve cutting away material, thread rolling utilizes applied pressure to deform the material into the desired thread form. This method offers several advantages, including improved material strength, enhanced surface finish, and greater dimensional accuracy. The hydraulic aspect of these machines provides controlled force application, which is essential for producing high-quality threads consistently.

Factors Influencing the Price

The price of high-quality hydraulic thread rolling machines can vary significantly based on various factors

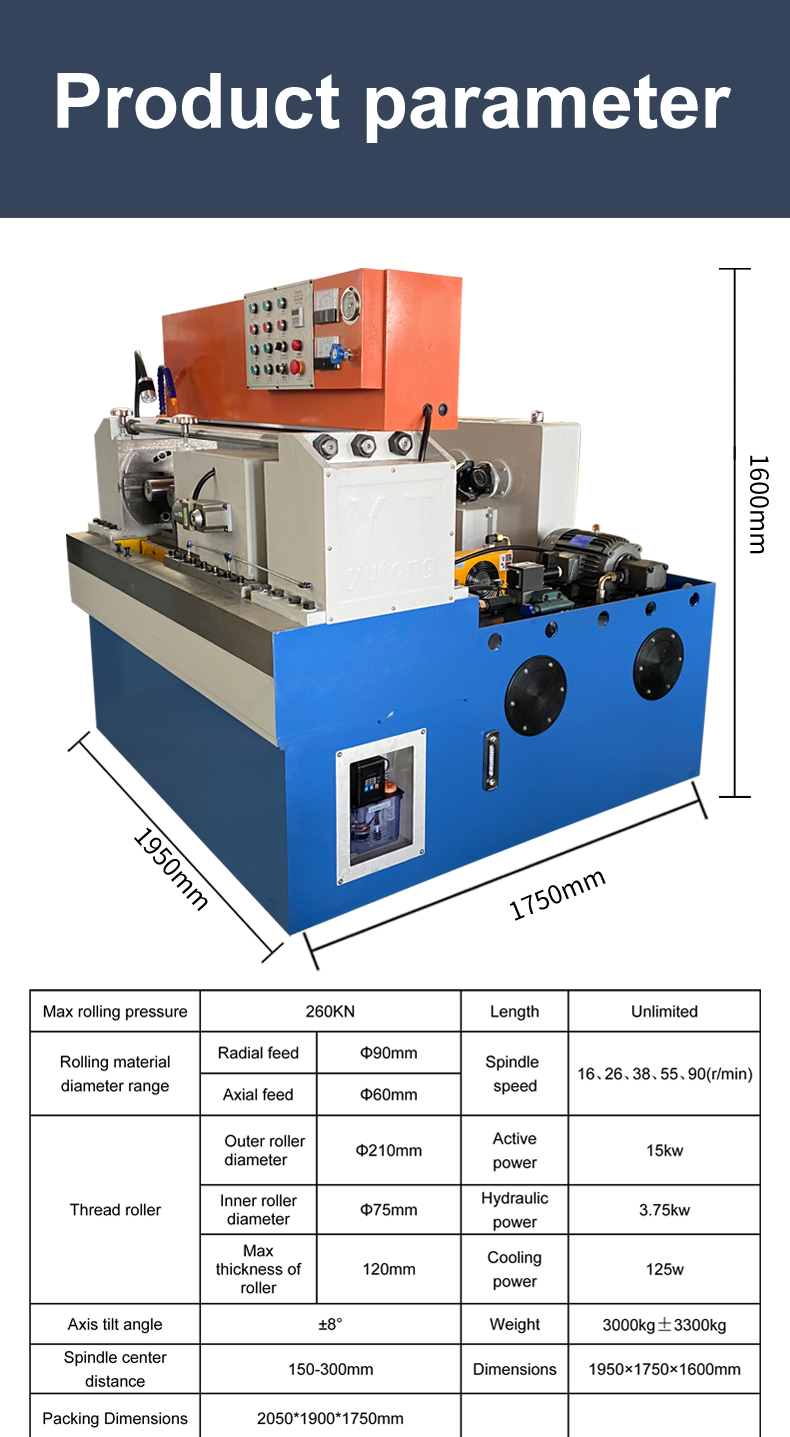

1. Machine Specifications The complexity of machine specifications, such as the size, capacity, and maximum rolling pressure, plays a significant role in pricing. Machines capable of handling larger diameters or producing finer threads often come with a higher price tag.

2. Brand and Manufacturer Established brands known for their reliability and technological advancements typically command higher prices. Companies investing in research and development often offer machines with innovative features that can justify the cost through enhanced performance and reduced operational downtime.

high quality hydraulic thread rolling machine price

3. Customization Many manufacturers require customized solutions tailored to specific production needs. Custom-built machines can be significantly more expensive than standard models, reflecting the additional engineering and manufacturing efforts involved.

4. Features and Technology Advanced features such as computerized controls, enhanced safety mechanisms, and automation options can elevate the price of hydraulic thread rolling machines. While these features may require a more considerable upfront investment, they often lead to lower labor costs and increased operational efficiency over time.

5. Market Demand and Economic Conditions The pricing of these machines can also be influenced by the current market demand and broader economic conditions. Fluctuations in raw material costs and changes in manufacturing trends can affect the overall pricing strategy of machine manufacturers.

The Investment Value

Though the initial cost of a high-quality hydraulic thread rolling machine can be substantial, it is essential to consider the long-term investment value. These machines can drastically reduce production times, increase throughput, and lower scrap rates. Moreover, the quality of the threads produced can lead to fewer customer complaints and warranty claims, ultimately contributing to a better bottom line.

Investing in a high-quality hydraulic thread rolling machine means investing in precision, efficiency, and reliability. Manufacturers must weigh the upfront costs against the potential for increased productivity and reduced operational costs over time.

Conclusion

In conclusion, while the price of high-quality hydraulic thread rolling machines can vary based on a multitude of factors, they represent a worthwhile investment for manufacturers seeking to enhance their production capabilities. As demand for high-quality components continues to rise across industries, having the right equipment can make a significant difference in maintaining a competitive edge. When selecting a machine, it is crucial for manufacturers to consider not just the price but also the overall return on investment, ensuring that their purchase aligns with their long-term production goals.