-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

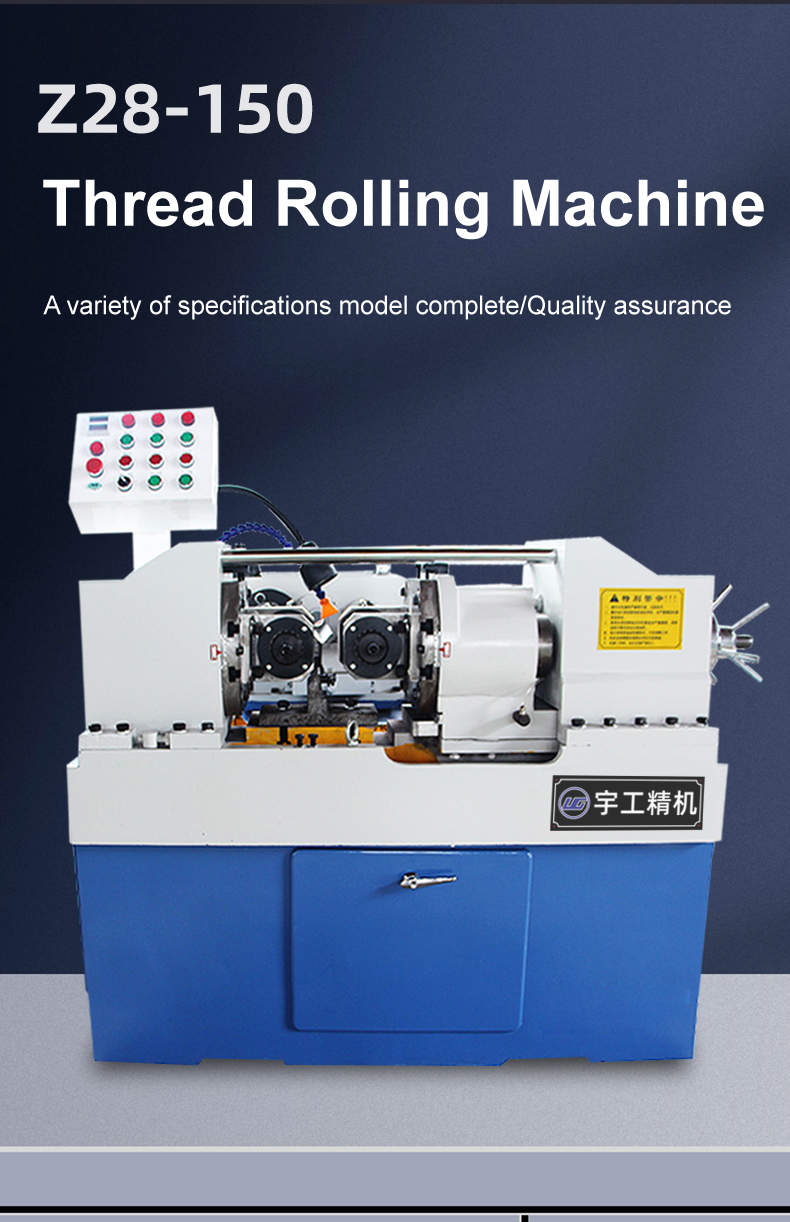

Affordable Small Thread Rolling Machines for Efficient Wholesale Production in Various Industries

The Importance of Wholesale Small Thread Rolling Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, the efficiency and accuracy of production processes are paramount. Among the various tools and technologies available to manufacturers, the small thread rolling machine has emerged as a vital piece of equipment, particularly in the wholesale sector. These machines play a crucial role in producing high-quality threaded components used in various industries, including automotive, aerospace, electronics, and consumer goods.

Thread rolling is a cold forming process that involves creating threads on a workpiece by displacing material rather than removing it. This process results in stronger threads due to the work hardening of the material, providing enhanced tensile strength and durability compared to traditional machining methods. The wholesale small thread rolling machine is specifically designed for mass production, enabling manufacturers to efficiently produce large quantities of threaded components with consistent quality.

One of the primary advantages of utilizing small thread rolling machines is their efficiency. These machines can significantly reduce production time, allowing manufacturers to meet the increasing demands of the market. Unlike conventional methods such as cutting and machining, thread rolling enables quick processing of various materials, including steel, aluminum, and various alloys. The result is a streamlined production process that contributes to higher output rates and reduced operational costs.

wholesale small thread rolling machine

Moreover, small thread rolling machines are known for their precision. With advancements in technology, these machines can achieve tight tolerances, ensuring that the threaded products meet the required specifications. This precision is crucial in industries where safety and reliability are paramount, such as in aerospace and automotive applications. High-quality threaded components can prevent product failures and enhance overall performance, thereby building trust and credibility with consumers.

In addition to efficiency and precision, the cost-effectiveness of small thread rolling machines cannot be overlooked. While the initial investment may be significant, the long-term savings realized through reduced material wastage, less energy consumption, and lower labor costs make them an economically sound choice for manufacturers. Furthermore, the durability of the components produced through thread rolling minimizes the need for costly rework and repairs, further enhancing profitability.

Sustainability is another aspect where small thread rolling machines have an edge. As industries aim to reduce their environmental footprint, the efficient use of materials in the thread rolling process aligns with these objectives. Since thread rolling displaces rather than removes material, it produces less waste and is more energy-efficient compared to traditional machining processes. This eco-friendly approach is increasingly becoming a priority for manufacturers who seek to balance productivity with environmental responsibility.

In conclusion, wholesale small thread rolling machines are indispensable tools in modern manufacturing. Their ability to enhance efficiency, precision, cost-effectiveness, and sustainability makes them highly attractive to manufacturers across various sectors. As the demand for high-quality threaded components continues to rise, investing in advanced thread rolling technology is a strategic decision for businesses aiming to stay competitive in an ever-evolving market. By leveraging the benefits of these machines, manufacturers can ensure they meet production demands while maintaining quality and operational efficiency.