-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 16, 2025 07:46

Back to list

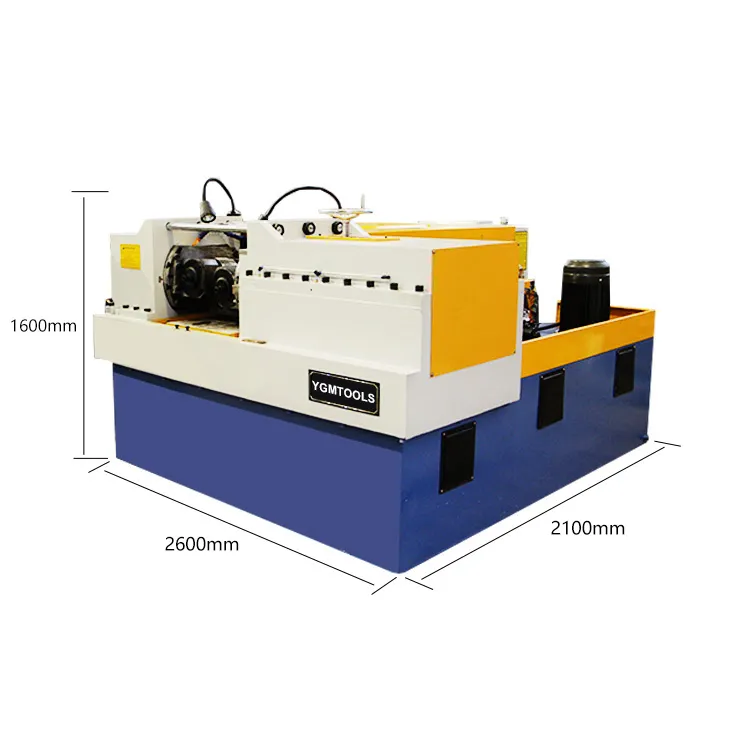

flat die thread rolling machine

Automatic thread rolling machines have revolutionized the manufacturing industry by providing a seamless, efficient, and cost-effective method for producing threads on various components. These machines are designed to handle diverse materials and dimensions while maintaining high precision and consistency, making them an indispensable tool in industries ranging from automotive to aerospace.

Establishing trustworthiness in the realm of automatic thread rolling machines involves understanding the specific requirements of each application and choosing the appropriate machine configuration to meet these needs. It is essential to source machines from reputable manufacturers who adhere to international standards of quality and safety. Investing in a machine from a well-regarded supplier not only ensures product reliability but also provides access to comprehensive support, including installation, training, and after-sales service. For businesses looking to integrate automatic thread rolling machines into their production line, it's important to consider factors such as the type and volume of products being manufactured, as well as the required precision and material characteristics. By collaborating with industry experts and leveraging the latest advancements in thread rolling technology, companies can streamline their manufacturing processes, achieve greater consistency in product quality, and ultimately enhance their competitive edge in the market. In conclusion, automatic thread rolling machines represent a significant leap forward in manufacturing technology, offering unparalleled efficiency, strength, and quality in thread production. Their ability to deliver consistent results while reducing operational costs makes them an invaluable asset for any manufacturer committed to excellence. As industries continue to evolve, embracing the capabilities of these machines will undoubtedly play a pivotal role in driving future innovations and successes.

Establishing trustworthiness in the realm of automatic thread rolling machines involves understanding the specific requirements of each application and choosing the appropriate machine configuration to meet these needs. It is essential to source machines from reputable manufacturers who adhere to international standards of quality and safety. Investing in a machine from a well-regarded supplier not only ensures product reliability but also provides access to comprehensive support, including installation, training, and after-sales service. For businesses looking to integrate automatic thread rolling machines into their production line, it's important to consider factors such as the type and volume of products being manufactured, as well as the required precision and material characteristics. By collaborating with industry experts and leveraging the latest advancements in thread rolling technology, companies can streamline their manufacturing processes, achieve greater consistency in product quality, and ultimately enhance their competitive edge in the market. In conclusion, automatic thread rolling machines represent a significant leap forward in manufacturing technology, offering unparalleled efficiency, strength, and quality in thread production. Their ability to deliver consistent results while reducing operational costs makes them an invaluable asset for any manufacturer committed to excellence. As industries continue to evolve, embracing the capabilities of these machines will undoubtedly play a pivotal role in driving future innovations and successes.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025