-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Available Thread Rolling Machines for Sale Ideal for Your Manufacturing Needs

Thread Rolling Machines for Sale A Comprehensive Guide

Thread rolling machines play a crucial role in modern manufacturing, providing an efficient way to produce various types of threaded components. The rise of automation and increasing demand for precision engineering have led to a growing market for these machines. In this article, we will explore the advantages of thread rolling machines, their applications, and considerations for purchasing one for your business.

What are Thread Rolling Machines?

Thread rolling machines are specialized equipment used to form threads on a variety of materials, typically metal. The process involves deforming the material by squeezing it between two rotating dies, resulting in a strong and precise thread profile. Unlike traditional cutting methods, thread rolling does not remove material; instead, it displaces it, leading to enhanced strength and fatigue resistance. This is particularly beneficial for applications in the automotive, aerospace, and construction industries, where durability is paramount.

Advantages of Thread Rolling

1. Increased Strength and Durability Thread rolling enhances the mechanical properties of the material. The cold working process increases tensile strength, making rolled threads less prone to stripping or breaking compared to cut threads.

2. Cost-Effective Production By producing threads without cutting, thread rolling machines minimize material waste and reduce production time. This efficiency translates to lower costs for manufacturers, making it an attractive option for high-volume production runs.

3. Precision and Consistency Thread rolling machines offer exceptional precision, ensuring uniform thread profiles that meet stringent specifications. This consistency is crucial for components that require exact fits and alignments.

4. Versatile Applications These machines can produce a wide range of thread sizes and types, including standard threads, custom designs, and specialized profiles. This versatility makes thread rolling suitable for various industries, from medical devices to high-performance automotive parts.

Factors to Consider When Buying Thread Rolling Machines

thread rolling machines for sale

1. Type of Machine There are different types of thread rolling machines available, including flat die and planetary machines. The choice depends on your specific production needs, such as the material, thread size, and volume.

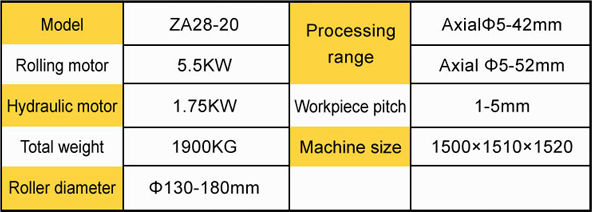

2. Machine Capacity Assess the machine's operational capacity to ensure it meets your production requirements. Consider factors such as the maximum material diameter, thread length, and production speed.

3. Automation Features Modern thread rolling machines often come with advanced automation features that enhance productivity. Look for options with programmable controls, automatic loading, and real-time monitoring systems.

4. Quality and Brand Reputation Invest in machines from reputable manufacturers known for their quality and customer support. Reading reviews and seeking recommendations can provide insight into the best options available.

5. After-Sales Support Choosing a supplier that offers excellent after-sales service can save your business time and money. Ensure that the manufacturer provides spare parts, maintenance services, and operational training.

Where to Find Thread Rolling Machines for Sale

The market for thread rolling machines is expanding, with various suppliers and manufacturers offering new and used machines. Online platforms, industrial equipment marketplaces, and trade shows are excellent resources for exploring options. Additionally, manufacturers often have sales representatives who can provide valuable information and assistance in selecting the right machine for your needs.

Conclusion

Investing in a thread rolling machine can significantly enhance your manufacturing capabilities, providing increased strength, precision, and efficiency. As you explore the options available for sale, consider your specific requirements and seek out reputable manufacturers to ensure a successful investment. With the right equipment, your business can meet the growing demand for high-quality threaded components in today’s competitive market.