-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

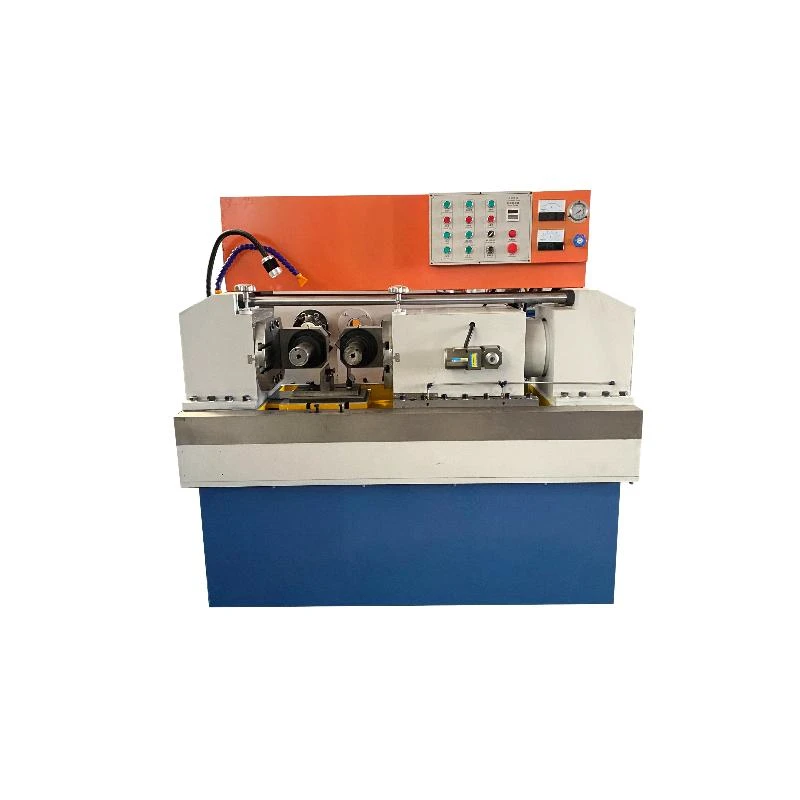

Top Quality Bolt Thread Rolling Machines for Precision Manufacturing Solutions

The Best Bolt Thread Rolling Machine A Comprehensive Guide

In the fast-paced world of manufacturing, efficiency and precision play crucial roles in ensuring that products meet the stringent demands of various industries. One essential piece of equipment that has become indispensable in the production of bolts and other fasteners is the thread rolling machine. This article explores the significance of the best bolt thread rolling machines, their operational principles, key features, and factors to consider when selecting the right machine for your needs.

Understanding Thread Rolling

Thread rolling is a cold-forming process that produces threads on cylindrical workpieces—primarily bolts, screws, and similar fasteners. Unlike traditional machining methods, which involve cutting material away, thread rolling employs tension and compression to deform the material, creating threads without removing any stock. This process not only enhances the mechanical properties of the threads but also improves the fatigue resistance of the finished products.

Importance of Thread Rolling Machines

Thread rolling machines are crucial in the manufacturing sector for several reasons. They offer remarkable advantages over conventional machining methods

1. Higher Strength Thread rolled components have superior tensile strength and durability. The cold working process increases the density of the material, reducing the likelihood of failure under stress.

2. Increased Production Rates These machines operate at higher speeds compared to traditional methods. They can produce threads in large quantities within a short time, making them ideal for high-volume production.

4. Improved Surface Finish The process generally yields a better surface finish, reducing the need for additional finishing operations.

best bolt thread rolling machine

Key Features to Look for in a Thread Rolling Machine

When choosing the best bolt thread rolling machine, several features should be considered to ensure optimal performance

1. Machine Type There are various types of thread rolling machines, including flat, cylindrical, and planetary models. The choice depends on the types of threads you intend to produce and the volume of production needed.

2. Capacity The machine's capacity in terms of thread size, length, and material type is vital. Ensure the machine can accommodate the specifications required for your products.

3. Control Systems Advanced control systems, including programmable logic controllers (PLCs) and touch screen interfaces, allow for precision in operation and ease of use. These systems can enhance productivity through automation.

4. Durability and Maintenance Consider the robustness of the machine and the ease of maintenance. A well-built machine reduces downtime and service costs over its lifespan.

5. Safety Features Safety should never be compromised. Look for machines equipped with safety guards, emergency stop functions, and other safety mechanisms to protect operators.

Conclusion

Investing in a high-quality bolt thread rolling machine can significantly impact your production capabilities and product quality. By understanding the benefits and identifying the key features of these machines, manufacturers can make informed decisions that align with their operational needs. The right thread rolling machine not only boosts productivity but also enhances the overall reliability of the products manufactured. In a competitive landscape where precision and efficiency are paramount, choosing the best bolt thread rolling machine is not merely a decision—it's a strategic advantage that can propel a business toward success.