-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 13, 2025 15:26

Back to list

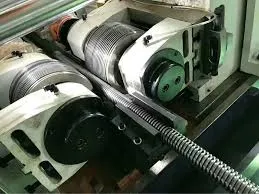

best roll thread machine price

Finding the best roll thread machine at an optimal price requires a blend of due diligence and in-depth market understanding. After all, thread rolling is an essential process in manufacturing that involves the creation of threads on screws, bolts, or other fasteners. When selecting a machine, it is crucial not only to focus on the price tag but also to examine aspects like performance, durability, and the support provided by the manufacturer.

Expert recommendations suggest looking into the manufacturer's service and support infrastructure. A machine is only as good as the support backing it up. Manufacturers who offer comprehensive training, prompt service, and readily available parts ensure that operations don’t come to a standstill due to unforeseen technical issues. Established brands often provide better technical support, as they have invested heavily in creating a reliable post-sale experience for customers. Warranty and after-sales services also significantly impact the purchasing decision. Trusted suppliers who stand by their products often provide extended warranties, reflecting confidence in their machine's longevity and reliability. A transparent warranty policy can be a decisive factor when choosing between similarly priced machines. Price considerations should not be secondary, but they must be balanced with an analysis of total cost of ownership. This involves calculating upfront costs alongside operational costs over the machine's lifespan. By focusing on both aspects, purchasers can ensure they get the best value for their investment. Finally, gathering testimonials and reviews from existing users can provide invaluable insights into how the machine performs in real production environments. Endorsements from peers can shed light on potential unforeseen issues and the practicality of the machine in day-to-day operations. In conclusion, determining the best roll thread machine price intertwines meticulous research with strategic evaluation of various parameters, ensuring that the machine meets your manufacturing demands while bolstering your return on investment. Leveraging industry expertise and knowledge can position buyers at an advantage, allowing them to make an informed, economically sound decision.

Expert recommendations suggest looking into the manufacturer's service and support infrastructure. A machine is only as good as the support backing it up. Manufacturers who offer comprehensive training, prompt service, and readily available parts ensure that operations don’t come to a standstill due to unforeseen technical issues. Established brands often provide better technical support, as they have invested heavily in creating a reliable post-sale experience for customers. Warranty and after-sales services also significantly impact the purchasing decision. Trusted suppliers who stand by their products often provide extended warranties, reflecting confidence in their machine's longevity and reliability. A transparent warranty policy can be a decisive factor when choosing between similarly priced machines. Price considerations should not be secondary, but they must be balanced with an analysis of total cost of ownership. This involves calculating upfront costs alongside operational costs over the machine's lifespan. By focusing on both aspects, purchasers can ensure they get the best value for their investment. Finally, gathering testimonials and reviews from existing users can provide invaluable insights into how the machine performs in real production environments. Endorsements from peers can shed light on potential unforeseen issues and the practicality of the machine in day-to-day operations. In conclusion, determining the best roll thread machine price intertwines meticulous research with strategic evaluation of various parameters, ensuring that the machine meets your manufacturing demands while bolstering your return on investment. Leveraging industry expertise and knowledge can position buyers at an advantage, allowing them to make an informed, economically sound decision.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025