-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

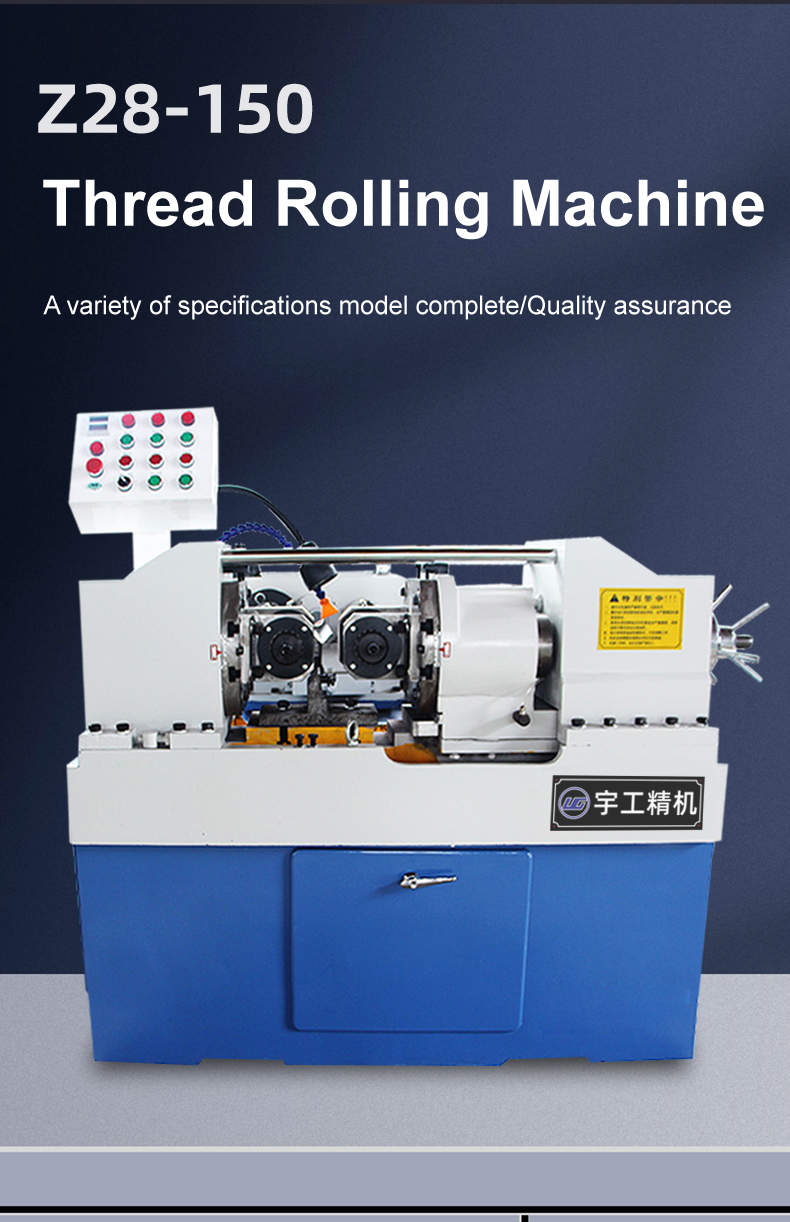

best small thread rolling machine

The Best Small Thread Rolling Machines A Comprehensive Guide

When it comes to precision machining, small thread rolling machines have emerged as invaluable tools in various manufacturing settings. These machines are designed to produce high-quality threads on small bolts, screws, and other fasteners, making them essential for industries such as automotive, aerospace, and electronics. With a growing demand for efficiency and accuracy, selecting the right thread rolling machine is crucial for any business involved in precision engineering.

What is Thread Rolling?

Thread rolling is a cold forging process that creates threads by deforming the material. Unlike traditional methods such as cutting or grinding, thread rolling enhances the mechanical properties of the material, resulting in stronger and more durable threads. This process also minimizes waste and significantly reduces production costs.

Key Features of Small Thread Rolling Machines

1. Compact Design One of the primary advantages of small thread rolling machines is their compact footprint. Ideal for small workshops or manufacturing environments where space is a premium, these machines deliver high efficiency without taking up valuable floor space.

2. Precision and Consistency Small thread rolling machines are engineered for precision. They produce consistent threads with excellent tolerances, which is critical for ensuring the interoperability of parts in assemblies. This reliability appeals to manufacturers who prioritize quality in their production processes.

best small thread rolling machine

3. Ease of Use Most modern thread rolling machines are designed with user-friendly interfaces and adjustable settings, allowing operators to switch between different thread sizes and types quickly. This flexibility helps manufacturers respond swiftly to changing production demands.

4. Durability Built from high-quality materials and components, these machines are designed to withstand rigorous use. Investing in a durable thread rolling machine can lead to long-term savings by minimizing maintenance and replacement costs.

Choosing the Right Machine

When selecting a small thread rolling machine, it's essential to consider several factors

- Material Compatibility Ensure that the machine can handle the types of materials you plan to work with, such as steel, aluminum, or plastics. - Thread Types and Sizes Look for machines that can accommodate a variety of thread sizes and profiles to meet your production needs. - Production Speed Evaluate the machine's production capabilities and how they align with your operational goals.

Conclusion

In conclusion, small thread rolling machines are indispensable in precision manufacturing, offering numerous advantages such as compact design, precision, and durability. By choosing the right machine tailored to your specific needs, you can enhance efficiency and product quality, ultimately driving your business's success in a competitive market. Whether you're a small workshop or a larger manufacturing facility, investing in a high-quality small thread rolling machine is a decision that will pay dividends in the long run.