-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

best thread rolling machine price

Understanding the Best Thread Rolling Machine Prices

When it comes to manufacturing and machining industries, thread rolling machines play a critical role in creating precise threads on rod materials. These machines are known for their efficiency and the quality of threads they produce, making them a preferred choice over traditional cutting methods. However, one key aspect that businesses must consider when investing in thread rolling machines is their cost. This article delves into the factors affecting the prices of the best thread rolling machines, helping businesses make informed decisions.

Factors Influencing Price

1. Type of Thread Rolling Machine The price of thread rolling machines varies significantly depending on their type. There are three main types flat, cylindrical, and planetary thread rolling machines. Flat rolling machines, which are commonly used for flat-stock materials, tend to be less expensive than cylindrical or planetary machines, which can handle more complex threading tasks. Planetary machines, in particular, are versatile and can produce multiple threads, but they come with a higher price point.

2. Machine Specifications Specifications such as the machine's capacity, speed, and work range also greatly influence the price. High-capacity machines that can handle larger diameters or faster production speeds are typically more expensive. Businesses must assess their production needs against these specifications to choose the right machine within their budget.

3. Brand Reputation The brand of the machine can also significantly impact its price. Established manufacturers with a reputation for quality and durability often charge premium prices for their products. Investing in a well-known brand may lead to better long-term reliability and customer service, potentially offsetting the initial cost.

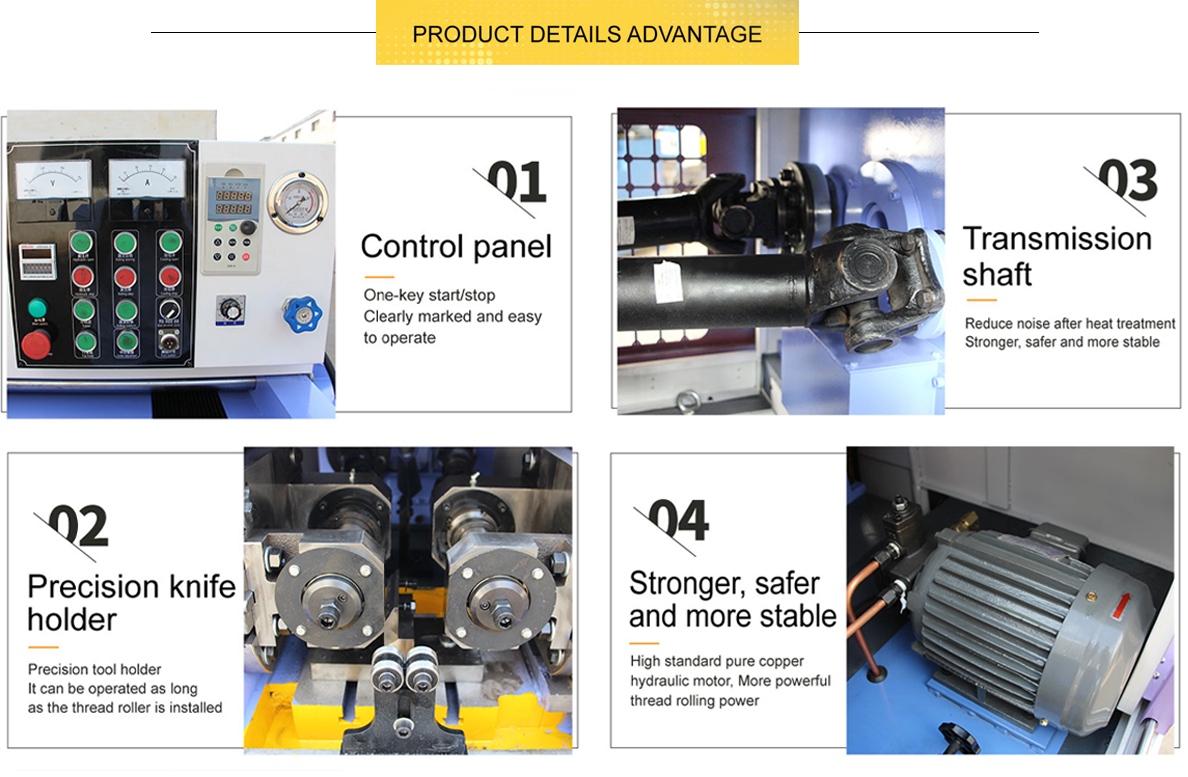

4. Technology and Features Modern thread rolling machines come equipped with advanced technology, such as computer numerical control (CNC) systems, which enhance precision and efficiency. While these machines may be more expensive upfront, they can offer significant savings in terms of labor and material waste over time. Additional features like automation, user-friendly interfaces, and integrated safety systems also contribute to higher pricing.

best thread rolling machine price

5. New vs. Used Machines Companies can choose between new or used thread rolling machines. New machines come with warranties and the latest technology but typically entail higher costs. On the other hand, used machines can offer substantial savings, but buyers must carefully inspect them for wear and condition to avoid future repair costs.

Understanding Market Trends

The market for thread rolling machines is influenced by various economic factors, including demand in the manufacturing sector and advancements in technology. In periods of economic growth, demand for new machines increases, potentially driving prices up. Conversely, during economic downturns, machine prices may decrease as manufacturers look to offload surplus inventory. Keeping an eye on market trends can help businesses anticipate price changes and make strategic purchasing decisions.

Cost Comparisons

When searching for the best thread rolling machine prices, businesses should gather quotes from multiple suppliers. Online marketplaces often provide comparative pricing models, enabling buyers to evaluate specifications across different brands and models. Additionally, contacting manufacturers directly can yield options for customizations that may better fit a company’s specific needs, influencing overall costs.

Conclusion

Investing in the best thread rolling machine for your business is crucial for maximizing production efficiency and thread quality. While prices can range significantly based on numerous factors, thorough research and careful consideration of your specific needs can help mitigate costs. By understanding the elements that influence pricing—including machine type, specifications, brand reputation, and market conditions—businesses can make informed decisions, ultimately leading to increased productivity and profitability. Whether opting for a new or used machine, investing in the right thread rolling technology is a critical step toward achieving long-term operational success.