-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

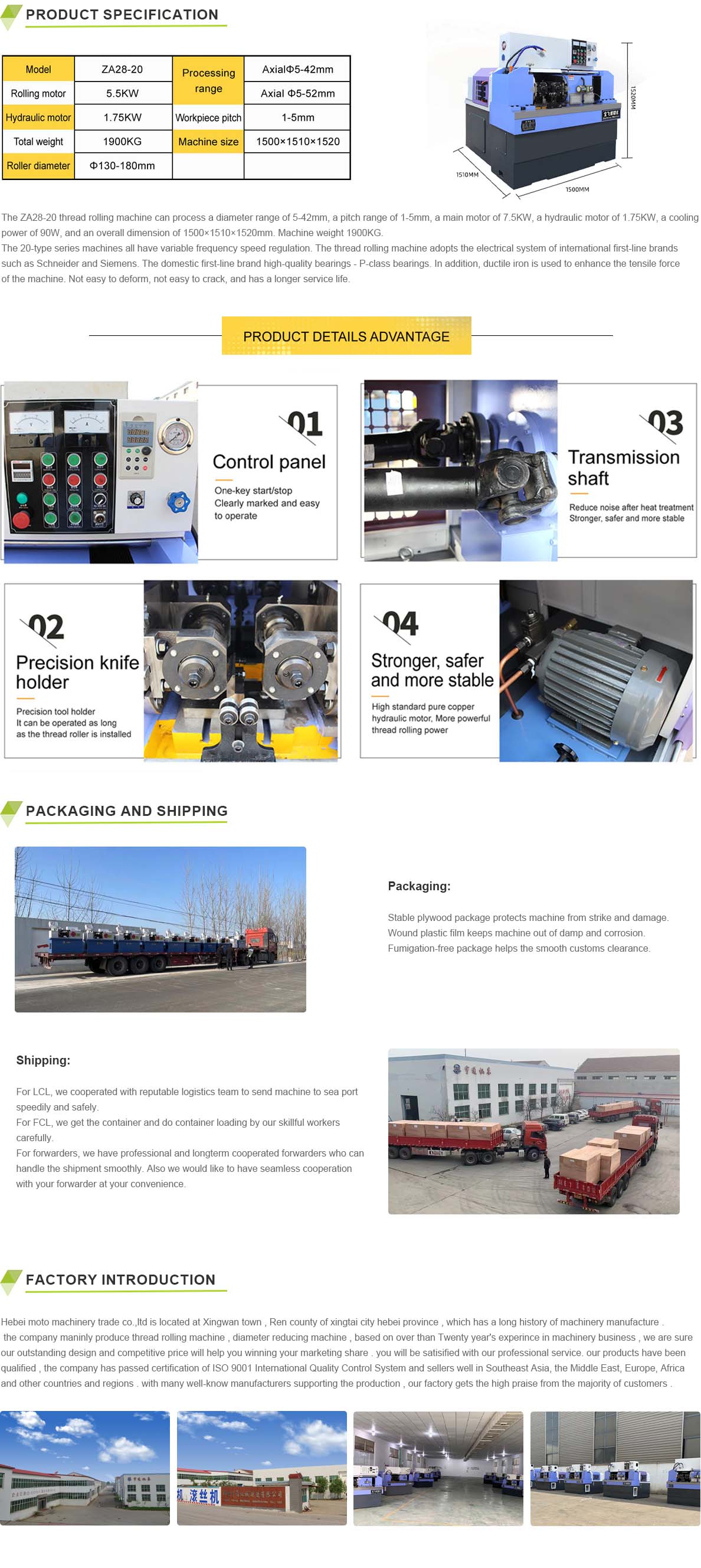

bolt rolling machine manufacturer

The Role of Bolt Rolling Machine Manufacturers in Modern Industry

In the fast-paced world of manufacturing, the efficiency and precision of production processes are paramount. Among the various technological innovations that contribute to enhanced production capability, bolt rolling machines stand out as essential equipment in the manufacturing of high-strength fasteners. This article explores the significance of bolt rolling machine manufacturers and the impact these machines have on modern industry.

Understanding Bolt Rolling Machines

Bolt rolling machines are specialized equipment used to produce bolts, screws, and other threaded fasteners from metal wire. The process of bolt rolling involves deforming the metal through a series of rollers, shaping it into the desired thread profile without removing any material. This not only preserves the integrity of the metal but also enhances the mechanical properties of the final product, making it stronger and more durable than bolts produced through traditional machining methods.

The operation of these machines is typically automated, allowing for high-speed production with minimal manual labor

. Manufacturers can produce thousands of fasteners in a short amount of time, meeting the demands of industries that require reliable and robust fastening solutions.The Importance of Bolt Rolling Machine Manufacturers

1. Innovation and Technology Advancements Bolt rolling machine manufacturers play a crucial role in the development and enhancement of rolling technology. They are at the forefront of research and development, continually striving to improve the efficiency, speed, and precision of their machines. By integrating advanced technologies such as computer numerical control (CNC), these manufacturers are able to produce machines that can operate with minimal human intervention, thus reducing the chances of error and increasing output quality.

bolt rolling machine manufacturer

2. Customization for Industry Needs Different industries require different specifications and designs for fasteners. Bolt rolling machine manufacturers understand this need for customization and often offer tailored solutions to meet specific requirements. This could encompass variations in size, shape, or material, ensuring that clients receive machines that are optimized for their particular production processes.

3. Durability and Reliability The manufacturing environment can be harsh, with machines often subjected to heavy usage. Established bolt rolling machine manufacturers focus on the construction quality and durability of their products. By using high-quality materials and robust engineering practices, they ensure that their machines can withstand the rigors of continuous operation, providing manufacturers with reliable and long-lasting equipment.

4. Support and Service Purchasing a bolt rolling machine is not just a one-time transaction; it involves a long-term relationship between the manufacturer and the client. Leading manufacturers provide extensive support services, including installation, training, and maintenance. This commitment to customer service helps manufacturers optimize their production processes, ensuring that their machines operate effectively throughout their lifespan.

5. Sustainability As industries become increasingly aware of the environmental impact of their operations, many bolt rolling machine manufacturers are adopting sustainable practices. This includes the development of energy-efficient machines, the use of recyclable materials, and the implementation of waste-reduction strategies. By prioritizing sustainability, these manufacturers contribute to a greener manufacturing landscape.

Conclusion

The role of bolt rolling machine manufacturers in modern industry cannot be overstated. Their innovative technologies, customizable solutions, focus on durability, and commitment to customer service are essential to optimizing the production of high-strength fasteners. As industries continue to evolve, the need for efficient and reliable fastening solutions will only grow, and bolt rolling machine manufacturers will be right at the forefront of this development. In a world where precision and quality are key, these manufacturers ensure that businesses can thrive by providing the necessary tools to meet industry demands. The relationship between manufacturers and bolt rolling machine suppliers is one of mutual growth, paving the way for advancements in technology, efficiency, and sustainability in manufacturing.