-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

bolt rolling machine suppliers

Understanding Bolt Rolling Machine Suppliers A Guide for Manufacturers

In the modern manufacturing landscape, efficiency and precision are paramount. One of the essential machines that contribute to these two aspects is the bolt rolling machine. These machines play a vital role in the production of bolts, screws, and other fasteners, ensuring that they meet rigorous quality standards and specifications. As demand for high-quality fasteners continues to grow, the need for reliable bolt rolling machine suppliers becomes increasingly critical. This article will explore the significance of choosing the right supplier and what to consider during the selection process.

The Importance of Bolt Rolling Machines

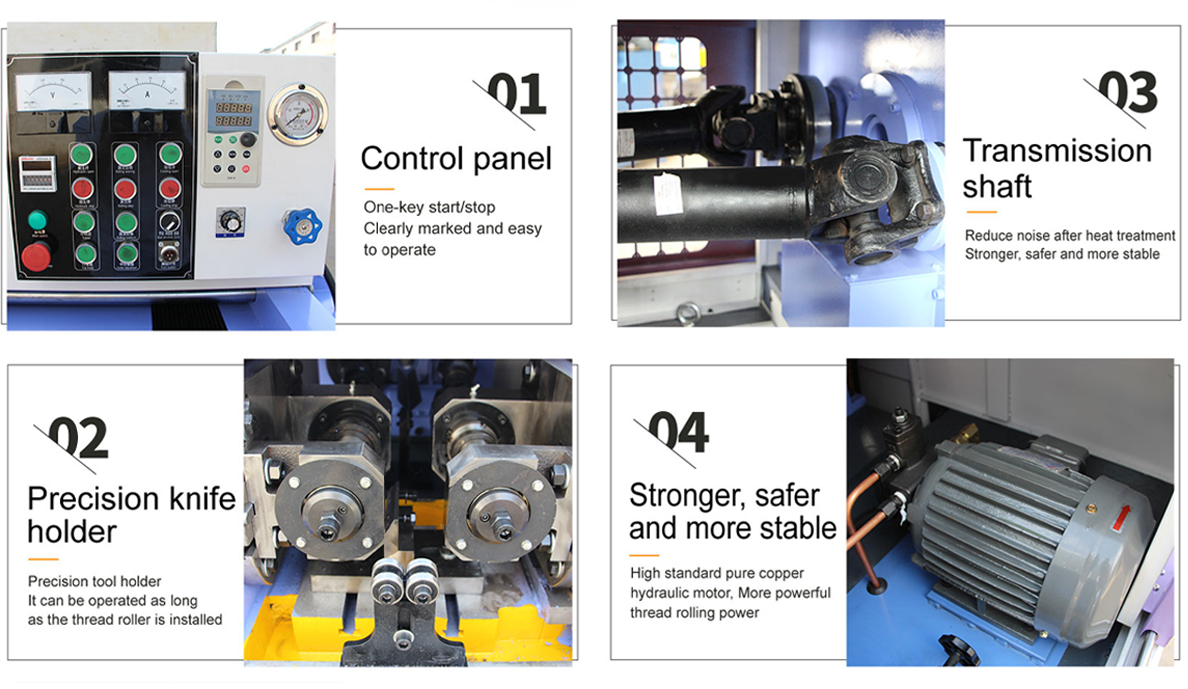

Bolt rolling machines are used to shape and form metal rods into bolts and other fastening components. These machines operate using various processes such as cold forging, which enhances the mechanical properties of the metal while reducing waste material. The efficiency of bolt production can significantly impact overall operational costs, making it imperative for manufacturers to invest in high-quality machines.

As manufacturers seek to optimize their production processes, they often turn to specialized suppliers who offer advanced bolt rolling machines. These suppliers are typically equipped with the latest technology and expertise in metalworking. Therefore, selecting a reliable supplier is crucial for ensuring that manufacturers have access to state-of-the-art machinery that can meet their production needs.

Key Considerations for Selecting Bolt Rolling Machine Suppliers

1. Quality and Reliability The first aspect to consider when selecting a supplier is the quality of their machines. High-quality machines reduce downtime and maintenance costs, contributing to more efficient operations. Manufacturers should look for suppliers with a reputation for reliability in their products, often evidenced by customer testimonials and case studies.

bolt rolling machine suppliers

2. Technical Support and Service A good supplier should offer comprehensive technical support. This includes installation services, training for operators, and ongoing maintenance. When machines operate smoothly, production runs efficiently, which is vital for manufacturers pressed for time and resources.

3. Customization Options Different manufacturers have varying requirements based on their production processes. Suppliers that offer customizable machines can be particularly beneficial. Whether it’s modifications for different bolt sizes or enhancing the machine’s capabilities for specific applications, customization can lead to more efficient production tailored to a manufacturer’s unique needs.

4. Innovation and Technology The fast-paced manufacturing world requires suppliers to keep up with the latest technological advancements. Suppliers who invest in research and development are more likely to offer innovative solutions that can enhance production capabilities. Features such as automation, precise control systems, and energy-efficient designs can significantly contribute to a manufacturer’s success.

5. Cost-effectiveness While quality is paramount, cost considerations cannot be ignored. Manufacturers must balance their budgetary constraints with their production needs. Suppliers that offer financing options, competitive pricing, and value for money can help businesses make informed decisions without compromising on quality.

6. Reputation and Experience The experience and track record of a supplier can provide insights into their reliability and capabilities. Established suppliers with years of experience in the industry are likely to have a deeper understanding of customer needs and market trends, making them valuable partners in production.

Conclusion

Choosing the right bolt rolling machine supplier is a crucial decision for manufacturers aiming to enhance their production capabilities. By considering factors such as quality, technical support, customization options, innovation, cost-effectiveness, and the supplier's reputation, manufacturers can find a partner that meets their needs effectively. As the demand for high-quality fasteners continues to rise, aligning with the right bolt rolling machine supplier can pave the way for sustained growth and success in the competitive manufacturing landscape. Investing time in selecting the right supplier will undoubtedly yield long-term benefits in productivity and efficiency.