-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Bolt Thread Rolling Machinery for Efficient Fastening Solutions

The Role of Bolt Thread Rolling Machines in Manufacturing

In the modern manufacturing landscape, the need for precision, efficiency, and consistency is paramount. One critical component that often gets overlooked is the machinery involved in the production of fasteners, such as bolts. Among these machines, the bolt thread rolling machine stands out due to its ability to produce high-quality threaded components with exceptional speed and accuracy.

Understanding Thread Rolling

Thread rolling is a cold-forming process that involves forging threads onto a workpiece by passing it between two dies. Unlike cutting methods that remove material to create threads, thread rolling displaces the material, resulting in enhanced strength and fatigue resistance. The process not only optimizes the physical properties of the bolts but also minimizes waste and saves energy, making it an environmentally friendly option.

The Mechanism of Bolt Thread Rolling Machines

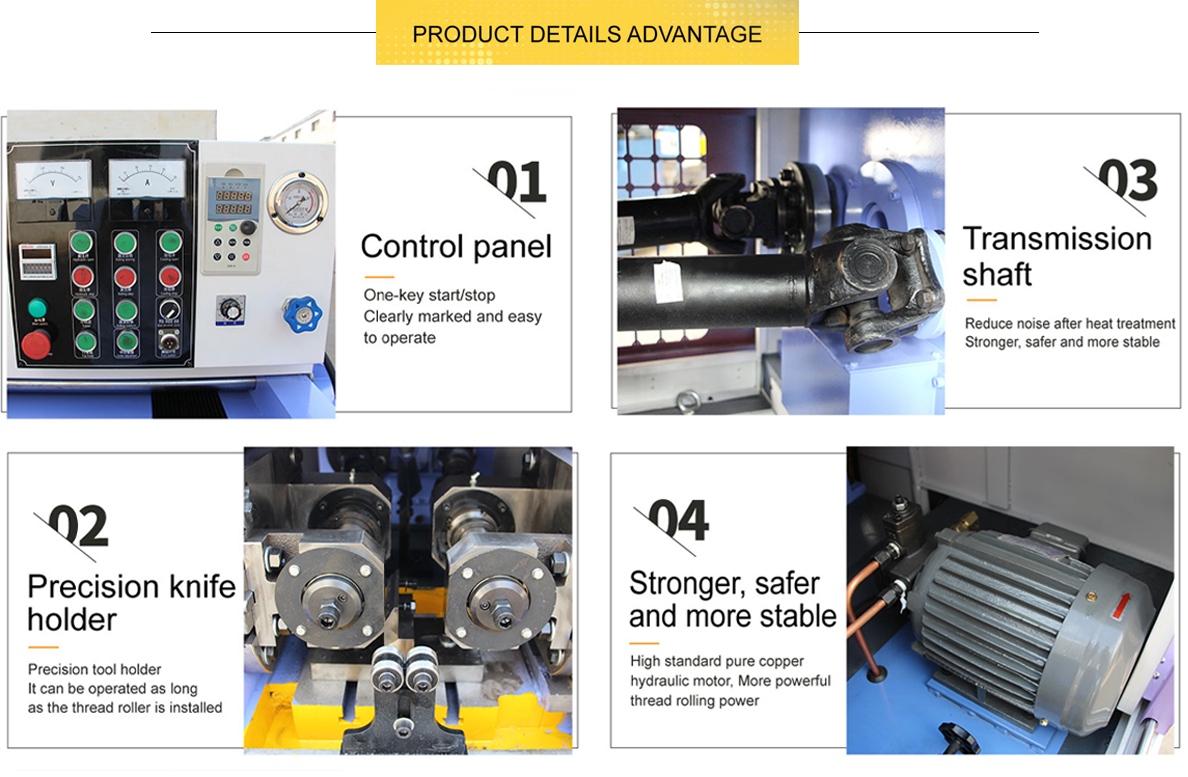

Bolt thread rolling machines are designed with precision engineering, incorporating advanced technology to achieve optimal performance. These machines come in various configurations, including flat and cylindrical thread rolling machines, each suited for different types of bolts. The choice of machine depends on factors such as the size of the bolt, the type of thread required, and the production volume.

Typically, a bolt thread rolling machine consists of a hydraulic or mechanical press, two vertically positioned dies, and a feeding mechanism. The process begins with the blank bolt being fed between the dies. As the machine operates, the dies move together to form the threads through a series of carefully controlled rotations. This not only shapes the bolt but also ensures that the threads are consistent and adhere to industry standards.

Advantages of Bolt Thread Rolling Machines

bolt thread rolling machine

The use of bolt thread rolling machines offers numerous advantages. Firstly, the cold-forming process maintains the integrity of the material, which leads to a stronger final product. Unlike traditional machining methods, which can introduce weak points, thread rolling retains the internal structure of the metal, resulting in superior fatigue resistance.

Secondly, production efficiency is greatly enhanced. Bolt thread rolling machines can operate at high speeds, producing thousands of bolts per hour. This efficiency reduces labor costs and allows manufacturers to meet high demand without sacrificing quality. Furthermore, the process is highly automated, reducing the likelihood of human error.

Thirdly, bolt thread rolling machines contribute to sustainability. The minimal waste produced in the thread rolling process, combined with lower energy consumption compared to cutting processes, makes it an attractive option for environmentally conscious manufacturers.

Applications of Bolt Thread Rolling Machines

Bolt thread rolling machines serve various industries, including automotive, aerospace, construction, and manufacturing. They are utilized in the production of a wide range of fasteners, such as screws, nuts, and bolts of different sizes and specifications. Reliable threaded fasteners are critical in many applications, from assembling machinery to constructing buildings, making the role of these machines essential in the supply chain.

Conclusion

In conclusion, bolt thread rolling machines play a pivotal role in the fastener manufacturing sector. They not only enhance the quality and strength of bolts but also improve production efficiency and sustainability. As industries continue to evolve and demand rises for high-quality fasteners, the importance of advanced machinery like bolt thread rolling machines will only grow. Investing in these technologies will ensure that manufacturers can meet the challenges of the future while maintaining the highest standards of quality and performance.