-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

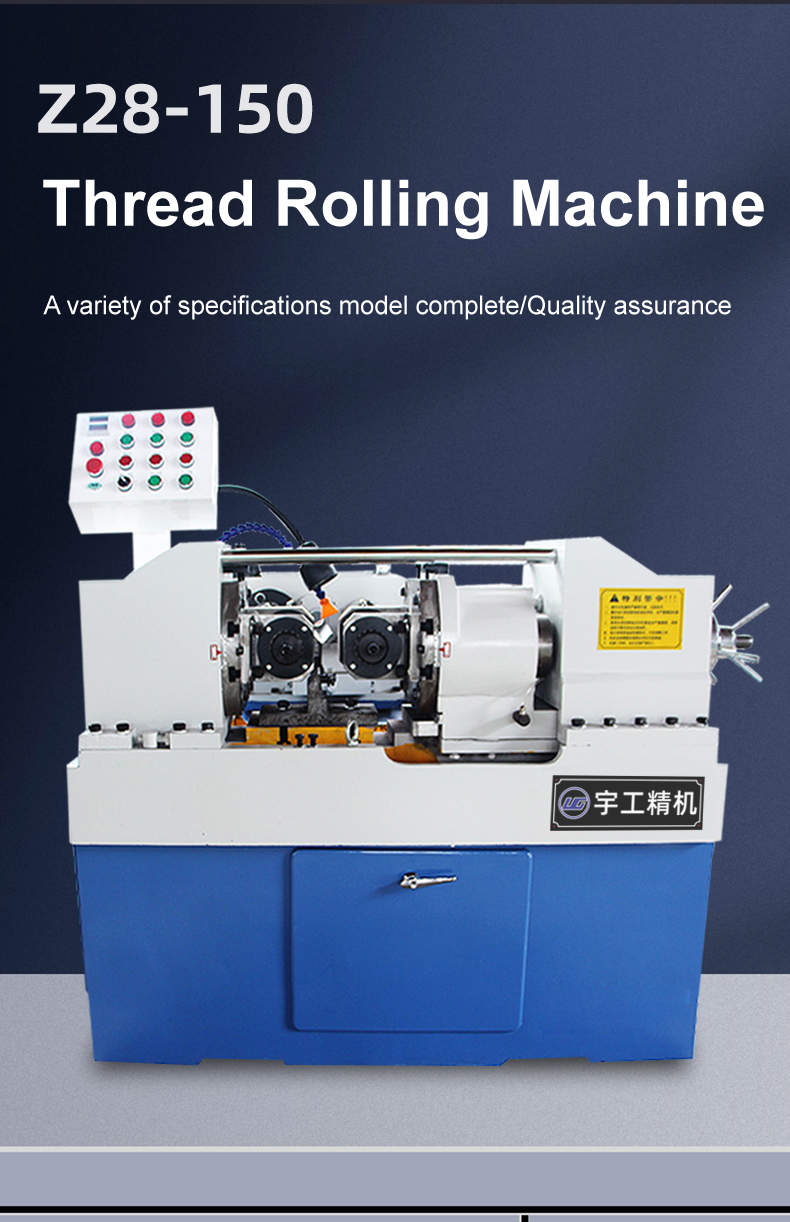

bolt thread rolling machine factory

The Evolution and Importance of Bolt Thread Rolling Machine Factories

In the contemporary manufacturing landscape, the production of high-quality fasteners such as bolts is paramount, particularly in industries like automotive, construction, and aerospace. At the heart of this production process lies the bolt thread rolling machine, a critical piece of machinery that facilitates the efficient and precise formation of threads on bolts and screws. As the demand for robust and reliable fastening solutions grows, so does the significance of bolt thread rolling machine factories.

Understanding Thread Rolling Technology

Thread rolling is a cold-forming process that creates threads through the plastic deformation of metal. Unlike traditional machining methods, which cut away material to form threads, thread rolling preserves the integrity of the material, resulting in stronger, more durable fasteners. This process not only enhances the mechanical properties of the bolts but also leads to reduced material wastage and increased production efficiency.

The primary types of thread rolling machines include flat die, cylindrical die, and reciprocating machines. Each type serves specific functions, from producing fine threads to accommodating various bolt sizes and shapes. The choice of machine is often determined by the manufacturing requirements, including the volume of production and the types of bolts being produced.

The Role of Factories in Innovation

Bolt thread rolling machine factories play a crucial role in the ongoing innovation of thread rolling technology. These factories are tasked with not only producing machines but also upgrading them to meet the evolving needs of the fastener industry. In recent years, there has been a significant shift towards automation and smart manufacturing solutions, where traditional machines are integrated with advanced technologies such as robotics and artificial intelligence. This evolution allows for greater precision, reduced labor costs, and higher output rates.

The emphasis on sustainability also impacts manufacturing practices within these factories. Modern bolt thread rolling machine manufacturers are increasingly focusing on developing machines that minimize energy consumption and reduce emissions. This growing concern for the environment aligns with global efforts to promote eco-friendly manufacturing processes, ensuring that industry advancements do not come at the expense of the planet.

bolt thread rolling machine factory

Quality Control and Standards

In the production of bolts, quality control is non-negotiable. Factories must adhere to strict industry standards and specifications to ensure that the fasteners meet safety requirements. Bolt thread rolling machine factories implement rigorous quality assurance protocols throughout the manufacturing process. This includes regular maintenance of machinery, comprehensive testing of finished products, and continuous improvements based on feedback from industry stakeholders.

Moreover, compliance with international quality standards such as ISO and ASTM is vital for factories aiming to compete on a global scale. Such adherence not only enhances the reputation of the manufacturers but also ensures that the products produced are reliable and consistent, which is crucial for industries where safety is paramount.

The Future of Bolt Thread Rolling Machine Factories

As we look to the future, the role of bolt thread rolling machine factories is set to evolve even further. The integration of Industry 4.0 technologies, such as IoT (Internet of Things) and big data analytics, will provide manufacturers with unprecedented insights into production efficiencies and potential areas for improvement. Predictive maintenance, for instance, can significantly reduce downtime and increase overall productivity.

Furthermore, with the advent of lightweight materials and new alloys, thread rolling machines will need to adapt to process these materials effectively. This adaptability will require continuous collaboration between machine manufacturers and their clients, fostering innovation that meets the specific needs of different industries.

Conclusion

In summary, bolt thread rolling machine factories are pivotal in ensuring the production of high-quality fasteners that meet the demands of various industries. Their commitment to innovation, quality control, and sustainability positions them at the forefront of manufacturing technology. As these factories evolve and adapt to new challenges and technologies, they will continue to play an essential role in shaping the future of the fastener industry.