-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 12, 2025 21:03

Back to list

bolt thread rolling machine factory

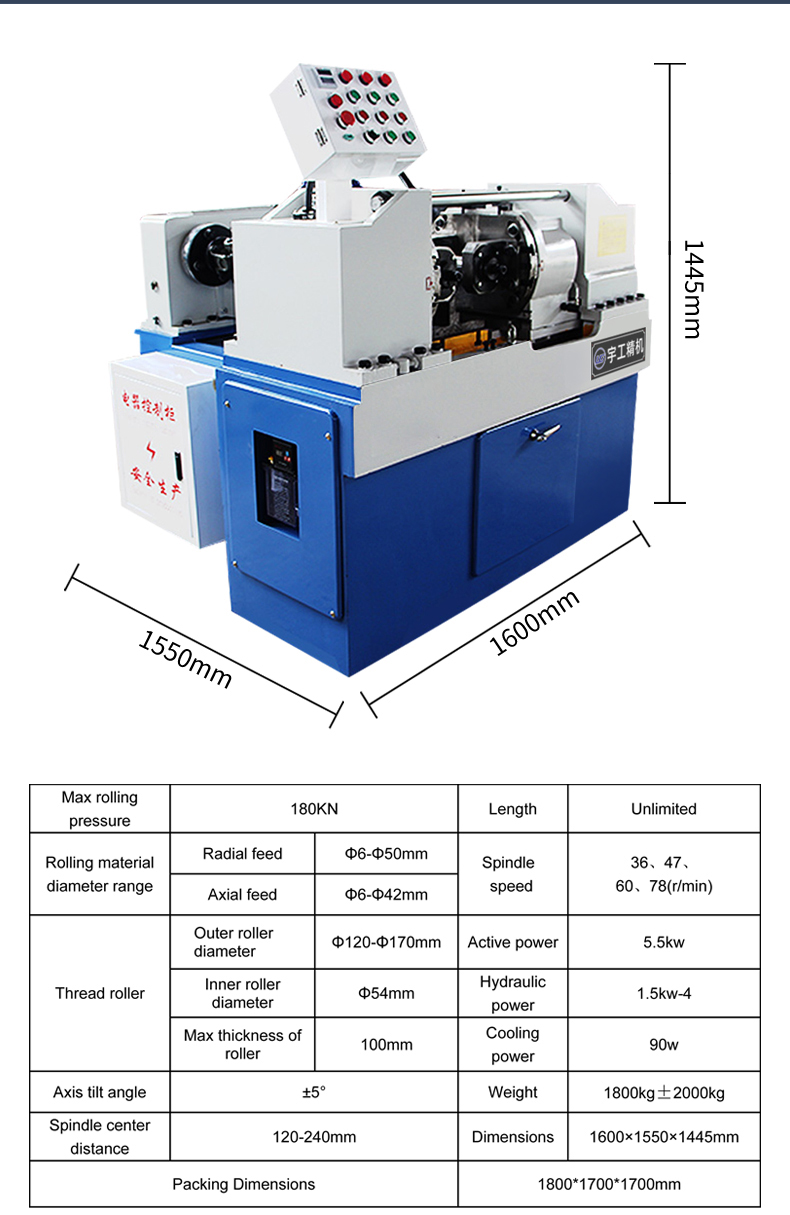

When it comes to the manufacturing of threaded fasteners, bolt thread rolling machines stand out as cornerstone equipment. These machines are pivotal in ensuring the precision and durability of threads, which are essential for the mechanical integrity and reliability of bolts. As a seasoned SEO expert focused on manufacturing technology, let us delve into the multifaceted world of bolt thread rolling machines, tapping into the product's experience, expertise, authoritativeness, and trustworthiness.

Trust is a key element fueling the relationship between bolt thread rolling machine manufacturers and their clients. Trustworthiness is earned by consistently delivering machines that perform reliably in demanding conditions. Manufacturers with a robust portfolio offer more than just machinery; they provide comprehensive support packages including installation, maintenance, and training. These services ensure that clients can maximize the potential of their thread rolling machines, thereby enhancing overall production efficiency. Furthermore, trust is solidified when a manufacturer takes a proactive stance on sustainability. The ecological impact of manufacturing processes is a growing concern. Leading bolt thread rolling machine factories incorporate energy-efficient systems, recycling protocols for coolant fluids, and noise reduction technologies. By advocating for and implementing sustainable practices, these manufacturers not only meet compliance requirements but also appeal to environmentally-conscious businesses. In conclusion, the realm of bolt thread rolling machine factories is defined by a confluence of experience, expertise, authoritativeness, and trustworthiness. Each aspect is interwoven, creating a tapestry that is resilient, reliable, and respected. As these factories continue to innovate, they ensure that the humble bolt, in all its threaded glory, remains a vital component of modern engineering and design, securing structures and systems around the globe.

Trust is a key element fueling the relationship between bolt thread rolling machine manufacturers and their clients. Trustworthiness is earned by consistently delivering machines that perform reliably in demanding conditions. Manufacturers with a robust portfolio offer more than just machinery; they provide comprehensive support packages including installation, maintenance, and training. These services ensure that clients can maximize the potential of their thread rolling machines, thereby enhancing overall production efficiency. Furthermore, trust is solidified when a manufacturer takes a proactive stance on sustainability. The ecological impact of manufacturing processes is a growing concern. Leading bolt thread rolling machine factories incorporate energy-efficient systems, recycling protocols for coolant fluids, and noise reduction technologies. By advocating for and implementing sustainable practices, these manufacturers not only meet compliance requirements but also appeal to environmentally-conscious businesses. In conclusion, the realm of bolt thread rolling machine factories is defined by a confluence of experience, expertise, authoritativeness, and trustworthiness. Each aspect is interwoven, creating a tapestry that is resilient, reliable, and respected. As these factories continue to innovate, they ensure that the humble bolt, in all its threaded glory, remains a vital component of modern engineering and design, securing structures and systems around the globe.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025