-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Affordable Quotes for Bolt Thread Rolling Machines and Equipment Solutions

Understanding Bolt Thread Rolling Machines A Comprehensive Overview

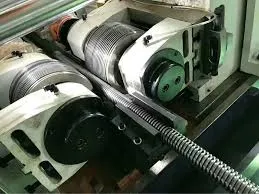

In the manufacturing landscape, the precision and efficiency of tool creation play a pivotal role. Among the myriad of machinery available, bolt thread rolling machines stand out for their ability to produce high-quality, uniform threads for bolts and fasteners. These machines are integral to various industries, including automotive, aerospace, and construction, where reliability and strength are paramount.

What is a Bolt Thread Rolling Machine?

A bolt thread rolling machine is designed to form threads on metal rods using a process known as thread rolling. Instead of cutting threads as done in traditional methods, this machine deforms the material through pressure, resulting in stronger and more resilient threads. The benefits of this method are numerous; it reduces waste, increases material strength due to work hardening, and enhances overall production efficiency.

Benefits of Using Thread Rolling Machines

1. Increased Strength One of the primary advantages of using a bolt thread rolling machine is the increase in the tensile strength of the finished product. Since the material is cold-worked, the grain structure is enhanced, providing better resistance to wear and fatigue compared to cut threads.

2. Material Efficiency Thread rolling produces minimal waste compared to cutting processes. The forming technique utilizes the entire volume of the material without the need for cutting away excess, allowing manufacturers to maximize their raw material usage.

3. Production Efficiency These machines are capable of high-speed operations, which means they can produce large quantities of threaded bolts in a short period. This efficiency is crucial for meeting the demands of fast-paced manufacturing environments.

4. Precision and Uniformity With advanced technology, modern bolt thread rolling machines offer high precision and consistency. This is critical in ensuring that all produced bolts meet the required specifications and standards, reducing the chances of defects.

Key Features to Consider When Choosing a Bolt Thread Rolling Machine

When looking to purchase or evaluate a bolt thread rolling machine, several key features should be considered

bolt thread rolling machine quotes

- Capacity The machine’s capacity in terms of the size and quantity of bolts it can produce is essential. This includes the maximum diameter and length of threads it can handle.

- Speed and Efficiency Consider the machine's cycle time and overall output. Higher speed capabilities can significantly affect production rates.

- Adjustment Mechanisms Ease of setup and adjustment is crucial. Machines that allow for quick changes in thread size and pitch can offer greater flexibility for manufacturers.

- Durability and Maintenance Given the stresses involved in rolling processes, choosing machines built with high-quality materials that require minimal maintenance can lead to long-term savings.

- Automation Features Incorporating automation and smart technology can enhance productivity by streamlining operations and reducing the need for manual intervention.

Current Market Trends

The demand for bolt thread rolling machines is on the rise as industries increasingly seek efficiency and sustainability. Manufacturers are investing in technology that not only enhances the production process but also meets environmental standards. Innovations in machine design are focusing on energy efficiency, reducing the carbon footprint of industrial operations.

Moreover, as global supply chains evolve, there is a greater need for local production capabilities. This shift is leading to an increased focus on acquiring advanced machinery, such as thread rolling machines, to meet the growing demand for quality fasteners.

Conclusion

Bolt thread rolling machines are a fundamental asset for manufacturers looking to produce high-quality threads with maximum efficiency. As industries continue to evolve, the significance of these machines will undoubtedly grow. Understanding the benefits, key features, and current market trends will place manufacturers in a better position to make informed decisions that can enhance their operational capabilities and product offerings. Investing in reliable thread rolling technology can prove to be a game-changer in producing strong, precise, and uniform threaded products essential for various applications across industries.