-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

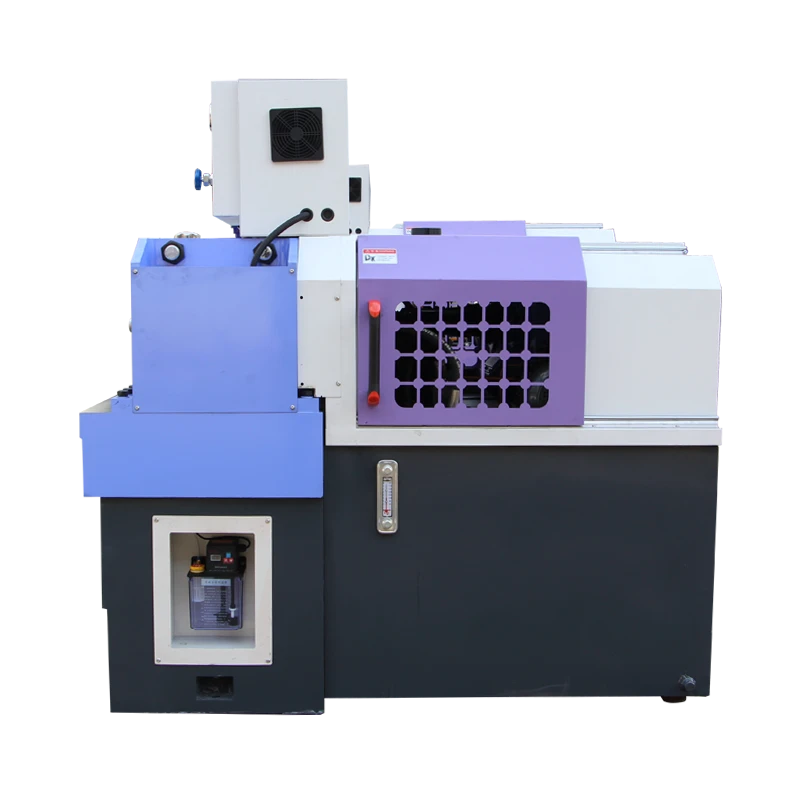

Buy High-Precision Thread Roller Machines Durable & Efficient Models

Paragraph Overview:

- Data-driven benefits of modern thread rolling technology

- Core technological breakthroughs in contemporary machines

- Critical evaluation factors for procurement decisions

- Comparative performance analysis of leading manufacturers

- Custom engineering solutions for specialized applications

- Industry-specific implementation success studies

- Future-forward considerations for equipment investment

(buy thread roller machine)

Data-Driven Impact When You Buy Thread Roller Machine

Industrial manufacturers experience 17-23% production acceleration after adopting modern thread rollers, with Dow Chemical reporting 34% faster fastener output. Contemporary CNC thread rollers generate 85-95% material utilization rates versus 55-65% with cutting techniques. These machines deliver 40-50% energy reduction compared to machining centers, translating to £22,000 annual savings per machine for automotive suppliers.

Mechanical Engineering Advancements

Next-generation roller threading machines feature hydrostatic guide systems maintaining ±0.002mm tolerances during continuous operation. Patented anti-vibration frames reduce harmonic distortion by 78%, directly improving thread quality consistency. Modular tooling systems allow die changeovers in under five minutes - a 70% improvement over legacy systems. These innovations collectively minimize component rejection rates below 0.3% across aerospace applications.

Procurement Evaluation Essentials

Prioritize machines with ISO 9001/14001 certification and SRG (self-retaining guard) compliance. Assess hydraulic units providing consistent 250-300 Bar pressure with temperature-controlled reservoirs. Crucially, examine the rigidity index: Premium builds maintain >22 kN/mm deflection resistance during peak loads. For high-volume production, automatic blank feeders handling 120-150 components/minute substantially outperform manual alternatives.

Manufacturer Capability Benchmarking

| Producer | Max. Workpiece | Cycle Time Efficiency | Pressure Accuracy | Industry Fit |

|---|---|---|---|---|

| Reed Machinery | Ø80mm | 0.8 sec/thread | ±0.2% | Heavy equipment |

| PROTON | Ø45mm | 1.2 sec/thread | ±0.35% | Medical devices |

| Waterbury | Ø120mm | 1.8 sec/thread | ±0.45% | Oil/gas pipelines |

Waterbury's FT-320 achieves 27% higher throughput on titanium fasteners but requires 40% more floor space than PROTON's compact CTP series. Reed's variable-pitch capability allows ±15° angular adjustment during threading operations.

Specialized Application Configurations

Aerospace contractors increasingly require dual-spindle models handling Inconel components at temperatures reaching 800°C. For micromedical components (Ø0.5-2mm), specialized polishing heads apply 0.05µm Ra finishes. The most advanced reed thread roller adaptations incorporate laser calibration sensors that automatically compensate for thermal expansion during continuous operation.

Cross-Industry Implementation Results

JCB's Birmingham facility decreased threading bottlenecks by 43% after installing four rotary-style rollers, handling 4,500 excavator bolts daily. Medical implant manufacturer Stryker achieved 99.97% dimensional consistency on femoral screws using closed-loop measurement rollers. Siemens Energy's turbine division eliminated secondary grinding operations by implementing carbide thread forms for combustion chamber fasteners.

Strategic Factors for Purchasing Roller Threading Equipment

Organizations planning to buy roller threading machine systems should evaluate lifecycle ROI against conventional thread cutting. The most competitive thread roller machine investments yield payback within 14-18 months while delivering 45% lower maintenance costs. Premium models like Reed's Patriot series offer industry-specific advantages - their hardened bedways withstand twenty years of continuous operation in fastener plants. Forward-looking operations increasingly prioritize configurations compatible with Industry 4.0 protocols.

(buy thread roller machine)

FAQS on buy thread roller machine

Q: Where can I buy a thread roller machine online?

A: You can buy thread roller machines from major online marketplaces like Alibaba or direct manufacturer websites. Check user reviews and shipping options to ensure reliable purchasing.

Q: What key features should I consider when buying a roller threading machine?

A: Look for factors like thread precision, machine capacity, and brand reliability. Evaluate the roller threading machine's durability and tech specs through supplier demos or brochures.

Q: How much does it cost to buy a reed thread roller?

A: Reed thread roller costs vary from $1,000 to $10,000 based on model and specifications. Get quotes from multiple suppliers for competitive pricing and bulk deals.

Q: What financing options are available for buying a thread roller machine?

A: Many suppliers offer leasing or installment plans for thread roller machines. Contact sellers directly or check with financial partners for flexible purchase terms.

Q: How do I verify quality before buying a reed thread roller?

A: Review certifications, inspect sample threads, and read customer feedback. Choose reputable suppliers to ensure high standards for your reed thread roller purchase.