-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 31, 2025 05:34

Back to list

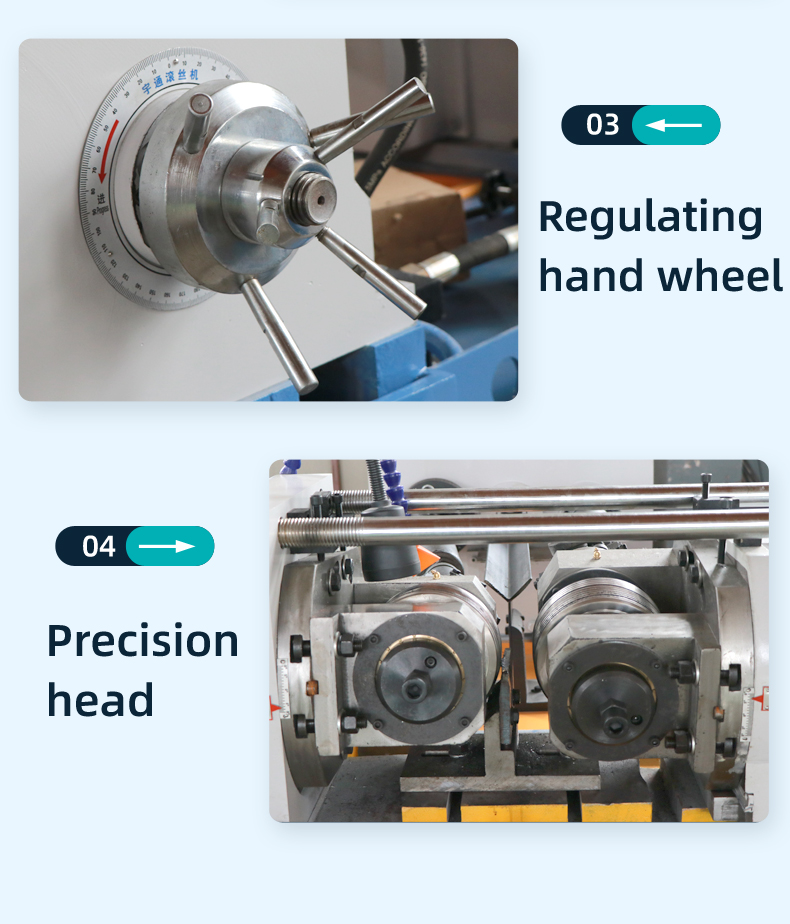

buy automatic thread rolling machine

Exploring the purchase of an automatic thread rolling machine can revolutionize manufacturing operations by enhancing efficiency and consistency. These sophisticated machines are essential for producing high-quality threaded components, pivotal to various industries such as automotive, aerospace, and construction.

Purchasing such machinery also requires attention to the installation environment. A suitable space with proper power supply, climate control, and adequate workflow layout ensures the machine operates at peak efficiency. Assessing the spatial and infrastructural needs before purchase prevents post-installation adjustments and costs. Automatic thread rolling machines also offer significant savings on raw materials. The cold-forming process produces less waste compared to traditional cutting methods, leading to more sustainable production practices. This not only reduces material costs but also aligns with corporate environmental objectives, making these machines a green investment as well as a practical one. One cannot overlook the strategic importance of maintenance in prolonging the lifespan of these advanced machines. Regular inspections, timely replacement of worn parts, and consistent lubrication are vital preventive measures. Some modern machines are equipped with diagnostic systems that alert operators of potential issues, enabling proactive maintenance and minimizing disruption. From an economic standpoint, the initial investment in an automatic thread rolling machine is offset by the increased efficiency and the consistency of production quality. The return on investment can be substantial, especially when tailored to the demands of high-volume production or stringent quality standards. Manufacturers often find that these machines not only boost throughput but also open new avenues for business due to enhanced capabilities. In conclusion, purchasing an automatic thread rolling machine is a strategic decision that can elevate a manufacturing operation to new heights. With their ability to deliver precision, efficiency, and durability, these machines address the complex needs of modern industries. By weighing factors such as quality, training, facility adaptation, and maintenance, companies can ensure that their investment leads to sustained success and operational excellence.

Purchasing such machinery also requires attention to the installation environment. A suitable space with proper power supply, climate control, and adequate workflow layout ensures the machine operates at peak efficiency. Assessing the spatial and infrastructural needs before purchase prevents post-installation adjustments and costs. Automatic thread rolling machines also offer significant savings on raw materials. The cold-forming process produces less waste compared to traditional cutting methods, leading to more sustainable production practices. This not only reduces material costs but also aligns with corporate environmental objectives, making these machines a green investment as well as a practical one. One cannot overlook the strategic importance of maintenance in prolonging the lifespan of these advanced machines. Regular inspections, timely replacement of worn parts, and consistent lubrication are vital preventive measures. Some modern machines are equipped with diagnostic systems that alert operators of potential issues, enabling proactive maintenance and minimizing disruption. From an economic standpoint, the initial investment in an automatic thread rolling machine is offset by the increased efficiency and the consistency of production quality. The return on investment can be substantial, especially when tailored to the demands of high-volume production or stringent quality standards. Manufacturers often find that these machines not only boost throughput but also open new avenues for business due to enhanced capabilities. In conclusion, purchasing an automatic thread rolling machine is a strategic decision that can elevate a manufacturing operation to new heights. With their ability to deliver precision, efficiency, and durability, these machines address the complex needs of modern industries. By weighing factors such as quality, training, facility adaptation, and maintenance, companies can ensure that their investment leads to sustained success and operational excellence.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025