-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

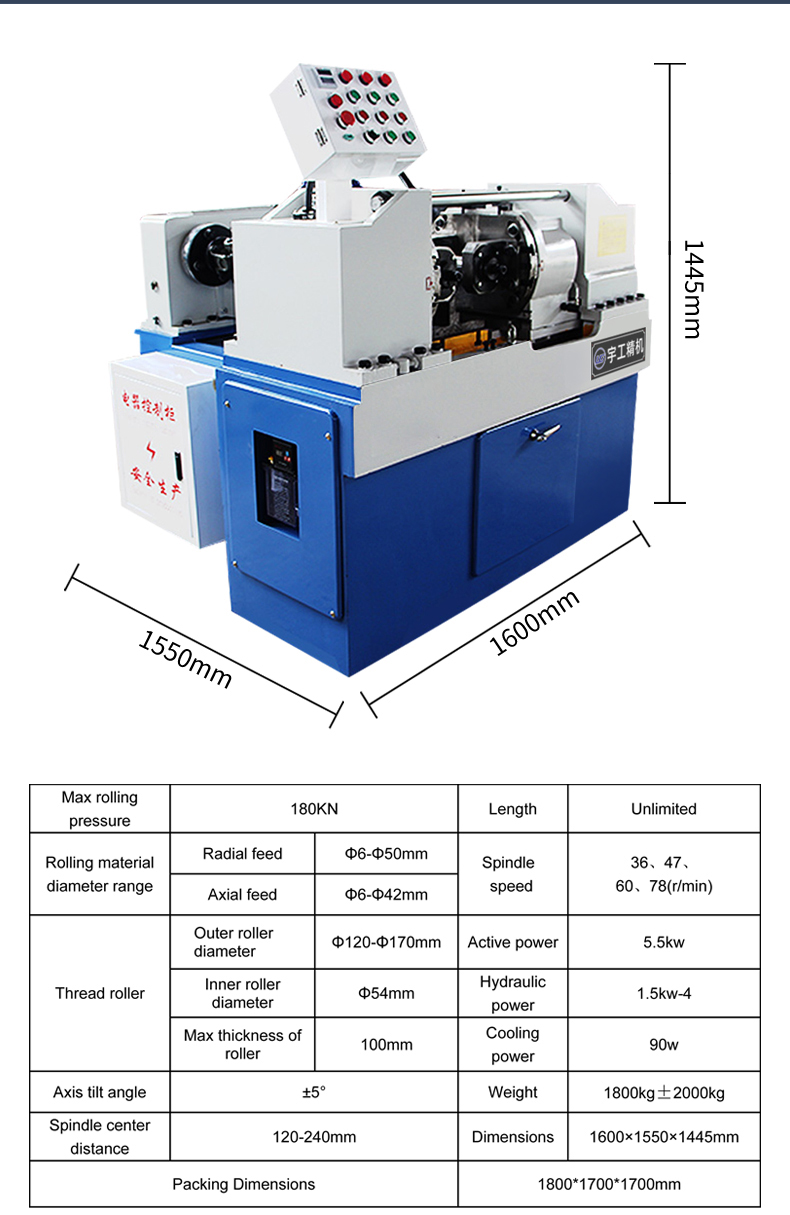

Explore Affordable CNC Thread Rolling Machines for Your Manufacturing Needs

The Benefits of Investing in CNC Thread Rolling Machines

In today's manufacturing landscape, precision and efficiency are paramount. One of the key technologies that has emerged to address these demands is the CNC (Computer Numerical Control) thread rolling machine. These machines play a crucial role in producing high-quality threaded components, which are essential in various industries, including automotive, aerospace, and electronics. If you are considering investing in a CNC thread rolling machine, here are some compelling reasons to make the leap.

Precision Engineering

CNC thread rolling machines provide exceptional precision in the production of threaded parts. Unlike traditional machining methods, which often involve cutting and may leave significant material waste, CNC thread rolling uses the cold forming process to create threads directly from the material. This not only reduces the chance of defects but also enhances the structural integrity of the threads. The use of advanced software and automation in CNC machines ensures that every part is manufactured to exact specifications, minimizing the need for rework.

Increased Efficiency

Efficiency is a critical factor in keeping manufacturing costs down. CNC thread rolling machines can produce threaded components at a significantly faster rate than manual or conventional machines. With the ability to operate continuously with minimal human intervention, these machines can increase production rates, enabling businesses to fulfill larger orders in shorter time frames. Additionally, the automated nature of CNC machines reduces downtime associated with tool changes and setup, further enhancing productivity.

Cost-Effectiveness

buy cnc thread rolling machine

While the initial investment in a CNC thread rolling machine may seem substantial, the long-term savings outweigh the upfront costs. The reduction in material waste, labor costs due to automation, and increased production rates contribute to a lower overall cost per unit. Furthermore, the durability of threaded components produced via cold rolling often leads to fewer returns and warranty claims, resulting in additional cost savings for manufacturers.

Versatility and Flexibility

Modern CNC thread rolling machines are designed with versatility in mind. They can accommodate a variety of thread profiles and materials, making them suitable for an extensive range of applications. Whether you need to produce standard or custom-threaded parts, these machines can be programmed to achieve the required specifications quickly. This flexibility not only streamlines production processes but also enables manufacturers to respond swiftly to changing market demands.

Sustainability Considerations

In an era where sustainability is a significant concern, CNC thread rolling machines offer an environmentally friendly alternative to traditional machining methods. The cold forming process generates less waste material and consumes less energy, contributing to a smaller carbon footprint. By opting for CNC thread rolling technology, companies can improve their sustainability profile while still meeting their production goals.

Conclusion

Investing in a CNC thread rolling machine is a strategic decision that can yield numerous benefits for manufacturers. From precision and efficiency to cost-effectiveness and sustainability, these machines offer a robust solution for producing high-quality threaded components. As industries continue to evolve and demand greater efficiency and quality, the adoption of CNC technology will play a critical role in maintaining competitive advantage in the market. For businesses looking to enhance their manufacturing capabilities, exploring CNC thread rolling machines is a step toward future success.