-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Purchase Hydraulic Threading Machines for Efficient Industrial Operations

Buying a Hydraulic Threading Machine A Comprehensive Guide

If you are in the industrial sector, particularly in plumbing, construction, or manufacturing, a hydraulic threading machine is an indispensable tool. These machines are designed to create threaded connections in pipes, which are essential for ensuring that various components are securely joined. With the growing demand for these machines, it’s crucial to understand what to consider when buying a hydraulic threading machine.

Why Choose a Hydraulic Threading Machine?

Hydraulic threading machines offer several advantages over traditional manual threading methods. The most significant benefits include increased speed and efficiency, reduced physical strain on the operator, and consistent thread quality. Hydraulic systems provide more torque, allowing for the processing of thicker and tougher materials, which can enhance productivity in projects requiring extensive threading.

Key Features to Look For

When purchasing a hydraulic threading machine, certain features should be prioritized

1. Capacity and Size Make sure to choose a machine that can handle the pipe sizes and materials you typically work with. The capacity often ranges from small pipes to large industrial sizes. Consider the maximum diameter and wall thickness you will need to thread.

2. Hydraulic Power Unit (HPU) The HPU is crucial as it powers the threading machine. Ensure that the HPU is adequately rated to handle the threading task without overheating or underperforming. A good rule of thumb is to select a model with higher horsepower for more demanding jobs.

buy hydraulic threading machine

3. Mobility Depending on your work environment, mobility can be an essential feature. Some machines come with wheels for easy transport, while others are more stationary. If you frequently move between job sites, look for a lightweight and portable option.

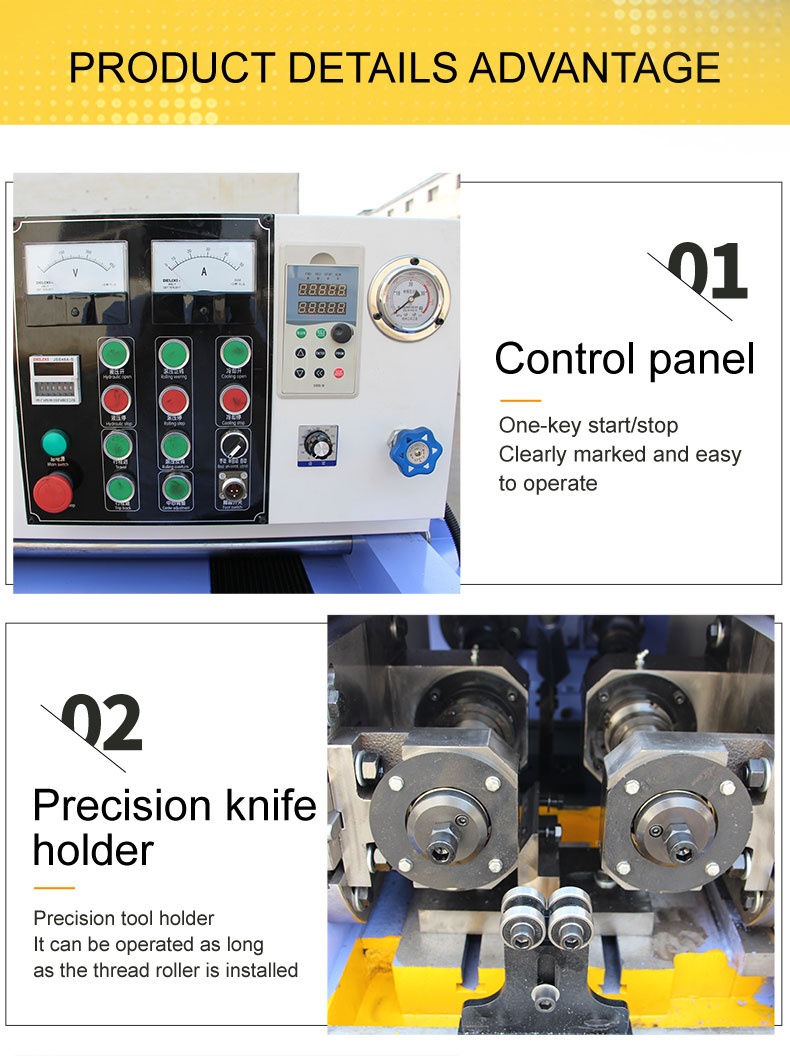

4. Ease of Use A user-friendly design is vital for efficiency and safety. Look for machines that offer intuitive controls and a manual that outlines the operating procedures clearly. Some models even come with digital displays for easier monitoring of operations.

5. Safety Features Hydraulic machines can be dangerous if not handled properly. Look for features such as overload protection, emergency stops, and safety guards to reduce the risk of accidents.

6. Cost and Warranty Set a budget before shopping, but also remember that the cheapest option may not always be the best. A good balance of quality and price is essential. Additionally, check the warranty details; reputable manufacturers often offer warranties ranging from one to three years.

Additional Considerations

Before making your purchase, it's beneficial to read customer reviews and ask for recommendations. Networking with other professionals who use hydraulic threading machines can provide insight into which models have proven reliable over time.

In summary, investing in a hydraulic threading machine is a significant decision that can enhance your operational efficiency. By considering factors such as capacity, mobility, ease of use, and safety features, you can select a machine that meets your needs effectively. Take your time to research before making a purchase, ensuring you choose a model that will serve you well for years to come.