-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

buy mini thread rolling machine

Buying a Mini Thread Rolling Machine A Comprehensive Guide

In today's fast-paced manufacturing environment, operators are constantly seeking efficient and cost-effective solutions to enhance production quality and speed. One such solution that has gained popularity among manufacturers is the mini thread rolling machine. This compact yet powerful device is designed to convert plain bars into threaded rods, screws, and other fasteners with incredible precision. If you are considering investing in a mini thread rolling machine, this article will guide you through the key aspects to consider.

What is a Mini Thread Rolling Machine?

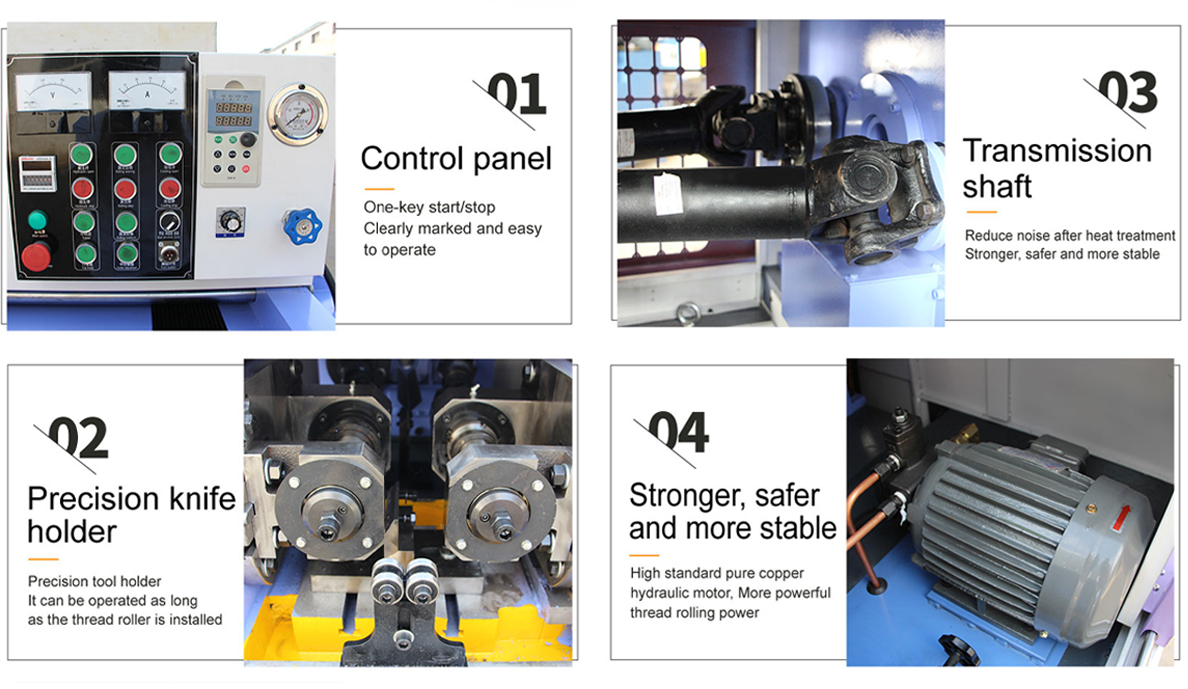

A mini thread rolling machine utilizes the process of cold forming to create threads on metal rods. Unlike traditional cutting methods, which remove material to create threads, thread rolling compresses the material, resulting in stronger and more precisely defined threads. This process not only enhances durability but also improves the overall accuracy of the finished product. Mini thread rolling machines are designed for small-scale operations or for workshops where space is limited but demand for high-quality threaded products remains high.

Benefits of Mini Thread Rolling Machines

1. Space-Saving Design As the name suggests, mini thread rolling machines are compact, making them ideal for small workshops or production lines where space is at a premium. Their efficient design allows for easy integration into existing operations without requiring significant floor space.

2. Increased Production Efficiency These machines can operate at high speeds, allowing manufacturers to produce a large volume of threaded components in a shorter time. This increased efficiency can significantly boost productivity and meet higher demand without sacrificing quality.

3. Cost-Effective Investing in a mini thread rolling machine can offer substantial cost savings in the long run. The cold-forming process reduces material wastage and minimizes the wear and tear on tools, translating to lower operational costs.

buy mini thread rolling machine

4. Enhanced Quality Control The precision of the mini thread rolling process ensures that each product meets stringent quality standards. The rolled threads are often more uniform and consistent compared to those produced by conventional cutting methods.

Considerations Before Purchase

1. Specifications Determine the specific requirements of your production needs, including the types of materials to be used, thread sizes, and production volume. This information will help you choose the right model that fits your operations.

2. Manufacturer Reputation Before making a purchase, research various manufacturers and their machines’ reliability. Opt for well-known brands that offer warranties and after-sales support to ensure you are making a sound investment.

3. Budget While mini thread rolling machines can be a cost-effective solution, they do come with varying price points. Establish a budget and compare different models to find one that offers the best value for money without compromising essential features.

4. Training and Maintenance Ensure that you have adequate training for your operators on the use and maintenance of the machine. Proper operation and regular maintenance are crucial for maximizing the lifespan and performance of your investment.

Conclusion

A mini thread rolling machine can be an invaluable asset for manufacturers looking to enhance productivity and quality while saving on costs and space. By considering the factors outlined in this guide, you can make an informed decision that will benefit your production process in the long run. Whether you’re a small workshop or part of a larger manufacturing operation, investing in a mini thread rolling machine could be the key to unlocking greater efficiency and success.