-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

buy wire thread rolling machine

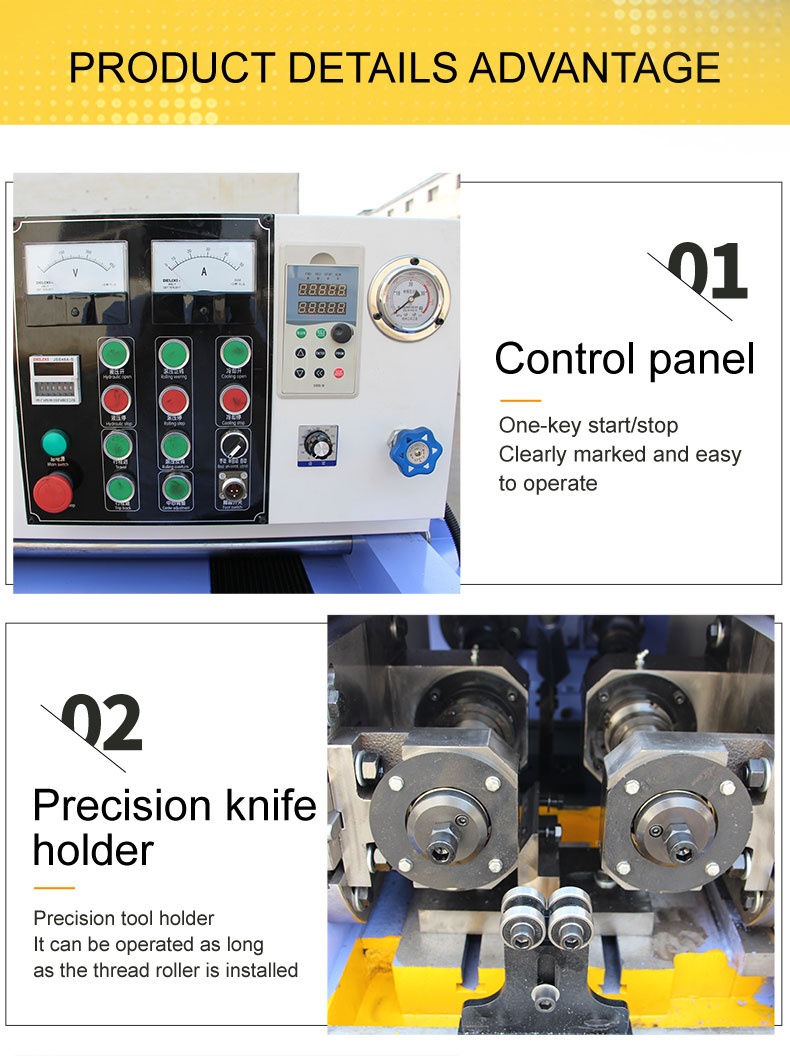

The Importance of Wire Thread Rolling Machines in Modern Manufacturing

In the fast-paced world of modern manufacturing, the efficiency and precision of production processes are paramount. One essential component in many industries is the wire thread rolling machine, a versatile tool that significantly enhances the production of threaded components. This article explores the functionality, advantages, and applications of wire thread rolling machines.

Understanding Wire Thread Rolling Machines

Wire thread rolling machines are specialized equipment designed to create threads on metal wires or rods without the removal of material. Unlike traditional cutting methods, which can result in waste and longer processing times, thread rolling utilizes a cold forming process. The machine applies a combination of pressure and rotary motion, which displaces the material to form a precise thread shape. This process not only increases the strength of the threads but also improves surface finish, making it ideal for high-quality applications.

Key Advantages

1. Efficiency One of the most notable advantages of wire thread rolling machines is their efficiency. The cold forming process allows for rapid production rates, making it possible to produce thousands of threaded components in a short amount of time. This efficiency is crucial in industries that demand high-volume production, such as automotive, aerospace, and general manufacturing.

2. Material Savings Since thread rolling does not cut away material but rather shapes it, this process results in less waste. This attribute not only reduces costs associated with raw materials but also minimizes the environmental impact of production, making it a more sustainable manufacturing option.

buy wire thread rolling machine

3. Improved Product Quality The threads produced through rolling are generally stronger and more uniform than those made by cutting processes. The cold forming method enhances the mechanical properties of the material, leading to improved fatigue resistance and overall durability. This is particularly important in applications where reliability is critical.

4. Versatility Wire thread rolling machines cater to a wide range of industries and can produce various thread profiles, including standard and custom designs. This versatility allows manufacturers to meet diverse client specifications and adapt to changing market demands effectively.

Applications in Various Industries

Wire thread rolling machines have applications in multiple sectors. In the automotive industry, they are used to create components like bolts, screws, and fasteners that require high tensile strength and precision. In construction, these machines are vital for manufacturing threaded rods and anchors used in structural applications. Additionally, the aerospace sector benefits from the production of lightweight, high-strength components that meet stringent safety regulations.

Conclusion

The wire thread rolling machine is an indispensable tool in contemporary manufacturing, offering unparalleled efficiency, material savings, and product quality. As industries continue to evolve, the demand for advanced manufacturing technologies will grow, and wire thread rolling machines will play a crucial role in meeting these challenges. Companies looking to enhance their production capabilities and maintain a competitive edge should consider incorporating this technology into their operations. Investing in a wire thread rolling machine not only streamlines manufacturing processes but also positions businesses for success in a rapidly changing market.