-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

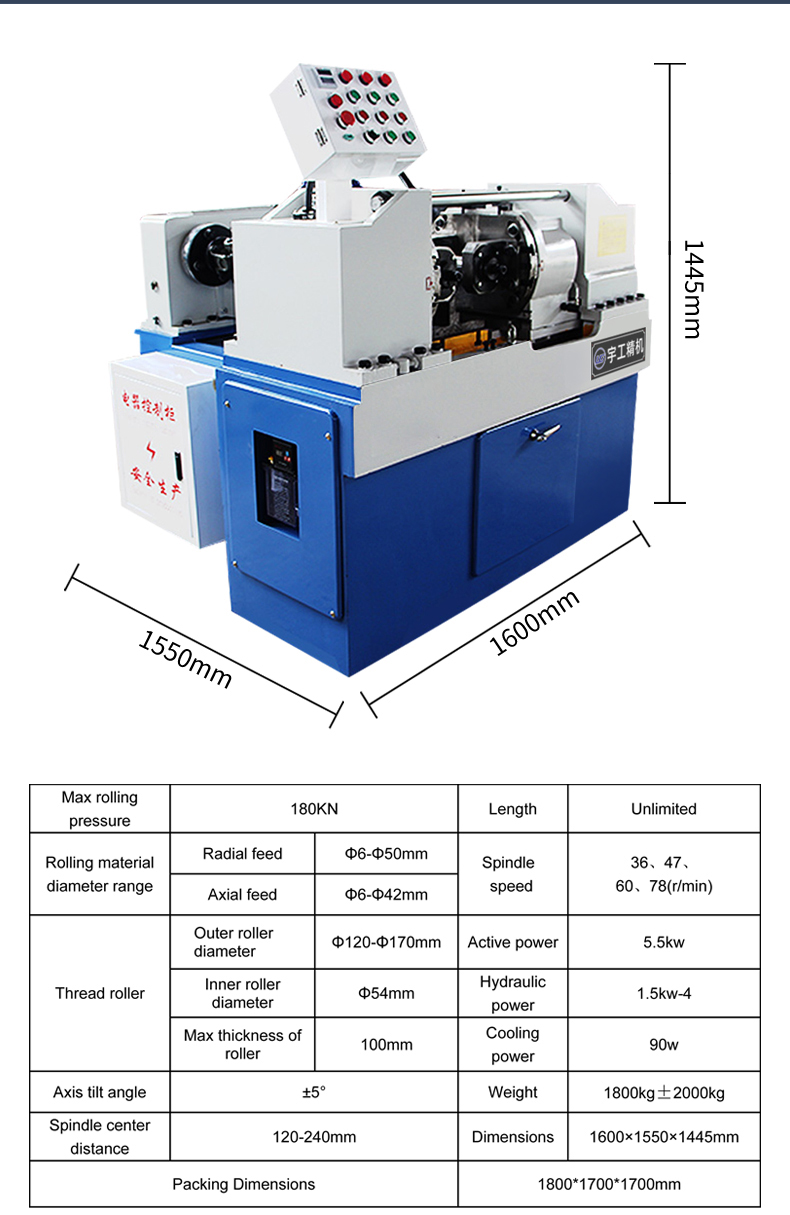

CE Certified Thread Rolling Machines Available for Purchase

CE Certification for Thread Rolling Machines A Comprehensive Overview

Thread rolling is a critical manufacturing process used to create strong and precise threads on metal parts. This technique offers superior strength compared to traditional cutting methods, making it suitable for various industries, including automotive, aerospace, and construction. As demand for high-quality thread rolling machines increases, so does the need for these machines to meet strict safety and quality standards, particularly through CE certification.

What is CE Certification?

CE certification indicates that a product meets the European Union's health, safety, and environmental protection standards. For manufacturers, obtaining CE marking is essential if they intend to market their thread rolling machines within the EU. This certification ensures that the product can coexist with other equipment without compromising safety or health regulations.

Importance of CE Certification for Thread Rolling Machines

1. Safety Assurance CE certification assures users that the machines have been tested and comply with safety standards. This reduces the risk of workplace injuries caused by machine malfunctions, thus protecting operators and maintenance personnel.

2. Quality Standards Thread rolling machines that are CE certified are held to high-quality standards. This means manufacturers can be confident in the durability, reliability, and overall performance of the machines they are purchasing or using.

3. Market Access For manufacturers and suppliers, CE certification is vital for accessing the European market. The CE mark signifies compliance with EU regulations, allowing companies to market their machines more extensively and gaining trust among European customers.

4. Competitive Advantage In a highly competitive manufacturing landscape, having CE certification can set a company apart from its rivals. It signifies a commitment to quality and safety, which can be a deciding factor for potential buyers.

The CE Certification Process for Thread Rolling Machines

ce certification thread rolling machines for sale

Obtaining CE certification involves several steps, including

1. Risk Assessment The first step is to identify potential hazards associated with the machine. This includes evaluating operational risks and ensuring adequate safety measures are in place.

2. Compliance with Directives Manufacturers must ensure that their machines comply with relevant EU directives, such as the Machinery Directive, which outlines essential health and safety requirements.

3. Technical Documentation Manufacturers must compile technical documentation demonstrating how their machines meet safety requirements. This documentation typically includes design and manufacturing processes, safety testing results, and user manuals.

4. Testing Independent testing by a notified body may be required to verify that the machine complies with all safety standards. This step is crucial for ensuring objectivity in the certification process.

5. Declaration of Conformity Once all requirements are met, the manufacturer must issue a Declaration of Conformity, confirming that the machine complies with all applicable EU legislation.

6. CE Marking Finally, the machine can be affixed with the CE mark, allowing it to be marketed and sold within the EU.

Conclusion

CE certification is an essential component for thread rolling machines, ensuring they meet stringent safety and quality standards necessary for the European market. By investing in CE certification, manufacturers enhance their product appeal, ensure compliance, and ultimately contribute to a safer working environment. As industries continue to evolve, having CE-certified equipment will be paramount for companies looking to maintain a competitive edge in the global marketplace. Embracing the CE certification process not only fosters trust among consumers but also aligns businesses with the best practices in manufacturing safety and quality.