-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ce certification types of thread rolling machine

Understanding CE Certification for Types of Thread Rolling Machines

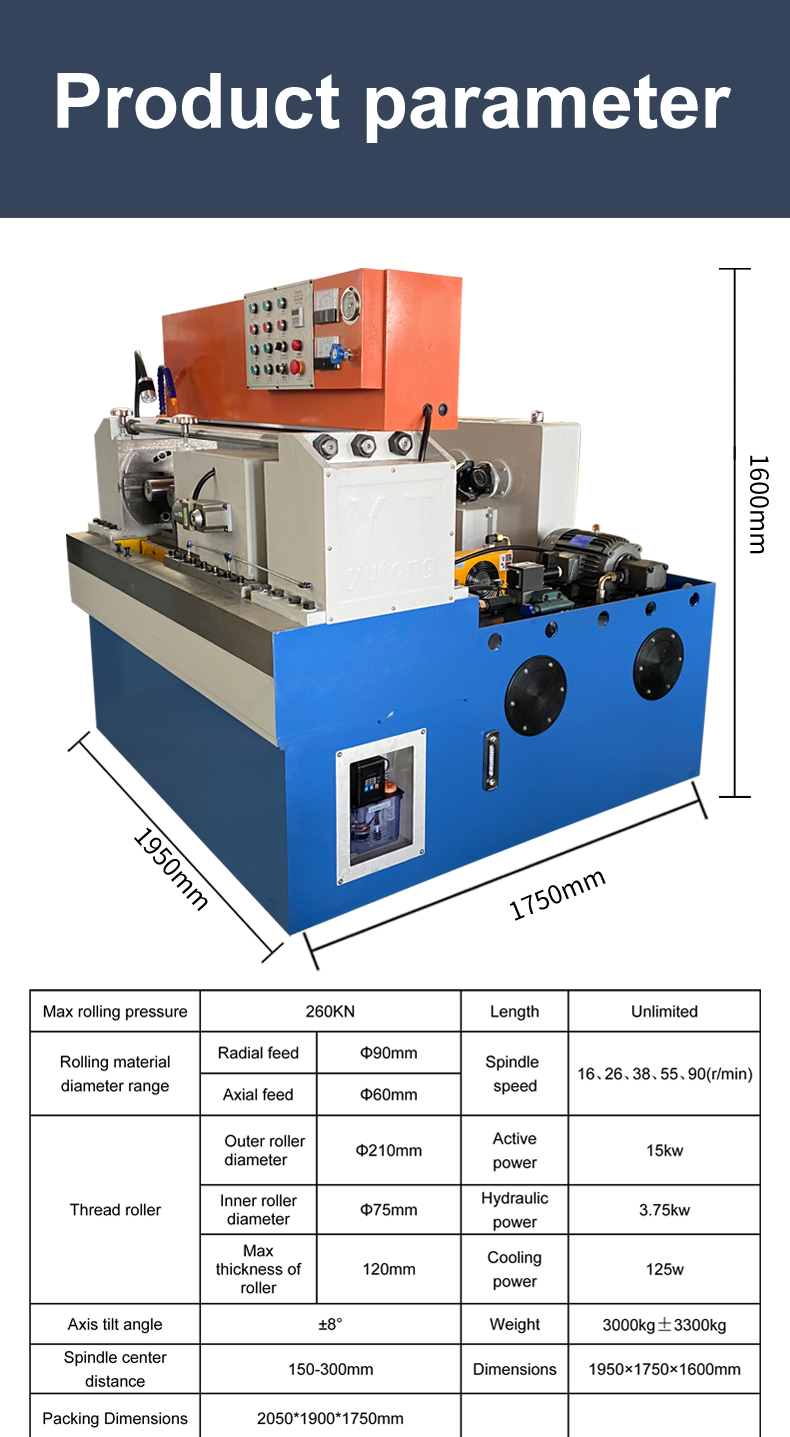

Thread rolling machines are essential tools in manufacturing, playing a critical role in the production of threaded fasteners such as screws, bolts, and nuts. These machines form threads by deforming the material, which results in strong and precise threads. Given the increasing demand for quality assurance and safety compliance in industrial machines, CE certification has become crucial for manufacturers and operators of thread rolling machines. This article delves into CE certification, its importance, and the various types of thread rolling machines that require this certification.

What is CE Certification?

CE marking is a certification mark indicating that a product meets the European Union (EU) safety, health, and environmental protection standards. The CE stands for Conformité Européenne, which translates to European Conformity. Obtaining CE certification is mandatory for many products sold within the European Economic Area (EEA), particularly those categorized under various directives such as the Machinery Directive, which directly pertains to industrial machines, including thread rolling machines.

Importance of CE Certification for Thread Rolling Machines

1. Safety Assurance CE certification ensures that thread rolling machines comply with stringent safety and health requirements, minimizing the risk of accidents and injuries in the workplace.

2. Market Access Products that bear the CE mark can be marketed and sold throughout the EEA without facing additional barriers. This facilitates a smoother market entry for manufacturers.

3. Quality Compliance The certification process compels manufacturers to maintain high standards in production and quality control, ensuring that the machines operate efficiently and reliably.

ce certification types of thread rolling machine

Types of Thread Rolling Machines and CE Certification

Thread rolling machines come in several types, each designed for specific applications and industrial requirements. Here are the most commonly used types, each of which must adhere to CE certification standards

1. Flat Die Thread Rolling Machines These machines use flat dies to create threads on cylindrical workpieces. They are typically used for producing screws and bolts with standard thread profiles. CE certification ensures these machines operate safely and meet mechanical standards.

2. Circular Die Thread Rolling Machines Utilizing circular dies, these machines are ideal for high-volume production of fasteners with more complex thread forms. The CE certification process assesses their design and operational safety features, ensuring they can handle the stresses of high-speed production.

3. Multi-Station Thread Rolling Machines These advanced machines incorporate multiple thread rolling stations, allowing for the simultaneous formation of threads on several workpieces. Due to the complexity and risks associated with their operation, achieving CE certification for multi-station machines is essential to confirm their safety and efficiency.

4. Inclined Thread Rolling Machines Designed for producing specific thread pitches and angles, these machines use inclined rolls to form threads accurately. CE certification evaluates their alignment, operation, and overall safety measures.

5. Hydraulic Thread Rolling Machines Utilizing hydraulic systems for power, these machines offer precise control and adaptability for various thread-size applications. The CE certification process scrutinizes these systems to ensure they are safe and compliant with hydraulic machinery regulations.

Conclusion

CE certification is a vital component for manufacturers and operators of thread rolling machines, ensuring that they meet safety, health, and environmental standards in the EU market. Understanding the different types of thread rolling machines and the CE certification requirements associated with them not only aids in compliance but also enhances product quality and reliability. Consequently, manufacturers should prioritize obtaining CE certification to promote safety, facilitate market access, and reduce legal liabilities while navigating the competitive landscape of the fastener industry. As demand for high-quality threaded products continues to grow, adhering to CE standards will be indispensable for success in the global market.