-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 13:23

Back to list

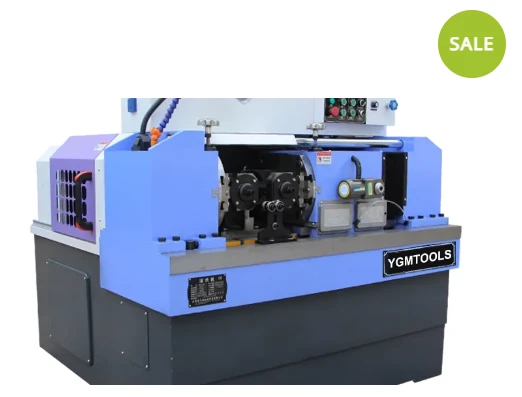

cheap thread rolling equipment

Investing in cheap thread rolling equipment can significantly enhance manufacturing processes for businesses seeking cost-effective solutions without compromising quality. Thread rolling is an indispensable process in the industrial sector, particularly in metalworking, where precision and strength are paramount. Despite its financial advantages, questions often arise about the reliability and efficiency of low-cost equipment. This article explores valuable insights into the utility, performance, and benefits of affordable thread rolling machinery, ensuring optimal outcomes for your production line while maintaining quality standards.

Authoritativeness from Reputable Manufacturers Many manufacturers producing low-cost thread rolling equipment maintain high authority in the industry. By leveraging cutting-edge technologies, these companies provide durable machinery with advanced features. Often, cheaper alternatives to high-end models benefit from similar engineering principles and tech innovations. Purchase decisions should consistently involve verifying manufacturer credentials, examining certifications, and ensuring adherence to international quality standards which signify commitment to excellence at an affordable price. Trustworthiness through Reliable Support Essential to procuring affordable thread rolling equipment is ensuring dependable after-sales support. Trustworthiness extends beyond the purchase phase, involving continued provision of maintenance, troubleshooting, and parts availability from the supplier. Companies that prioritize customer satisfaction typically offer robust support and transparent communication channels, enhancing buyer confidence, especially when dealing with economical machinery. Long-term partnership with trustworthy suppliers represents a fundamental asset, preventing operational disruptions while maximizing equipment lifespan. Conclusion Balancing Cost and Quality Choosing cheap thread rolling equipment doesn't have to mean sacrificing quality. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can adeptly integrate affordable machines into their production lines. Detailed evaluations prior to purchases and committing to reputable suppliers safeguard long-term operational goals. With strategic implementation, businesses can leverage economically priced machinery to perform at par with premium counterparts, reinforcing production capabilities and achieving sustained growth while embracing cost efficiencies.

Authoritativeness from Reputable Manufacturers Many manufacturers producing low-cost thread rolling equipment maintain high authority in the industry. By leveraging cutting-edge technologies, these companies provide durable machinery with advanced features. Often, cheaper alternatives to high-end models benefit from similar engineering principles and tech innovations. Purchase decisions should consistently involve verifying manufacturer credentials, examining certifications, and ensuring adherence to international quality standards which signify commitment to excellence at an affordable price. Trustworthiness through Reliable Support Essential to procuring affordable thread rolling equipment is ensuring dependable after-sales support. Trustworthiness extends beyond the purchase phase, involving continued provision of maintenance, troubleshooting, and parts availability from the supplier. Companies that prioritize customer satisfaction typically offer robust support and transparent communication channels, enhancing buyer confidence, especially when dealing with economical machinery. Long-term partnership with trustworthy suppliers represents a fundamental asset, preventing operational disruptions while maximizing equipment lifespan. Conclusion Balancing Cost and Quality Choosing cheap thread rolling equipment doesn't have to mean sacrificing quality. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can adeptly integrate affordable machines into their production lines. Detailed evaluations prior to purchases and committing to reputable suppliers safeguard long-term operational goals. With strategic implementation, businesses can leverage economically priced machinery to perform at par with premium counterparts, reinforcing production capabilities and achieving sustained growth while embracing cost efficiencies.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025