-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 11:31

Back to list

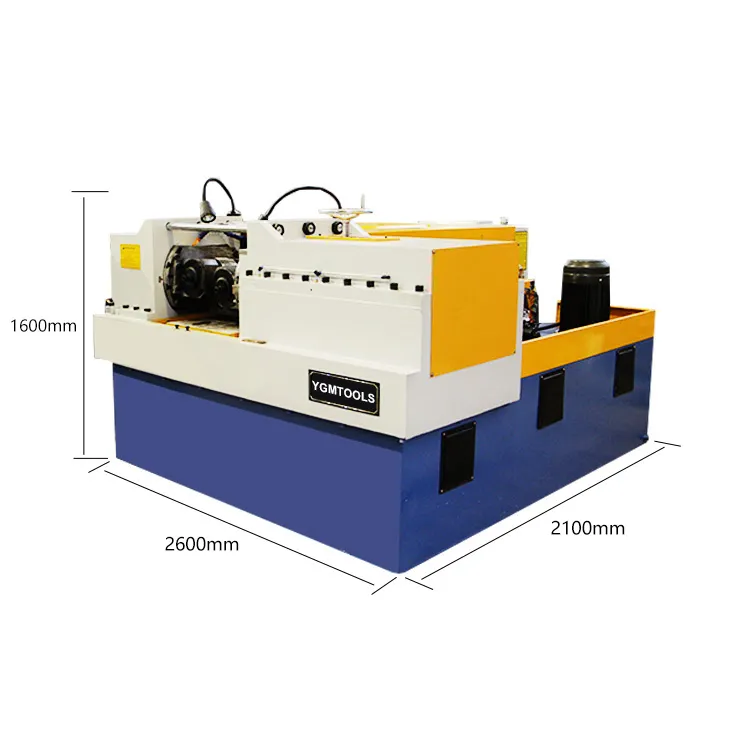

cheap thread rolling machine

Finding the right thread rolling machine is essential for any manufacturing business aiming to optimize production processes and reduce costs. Investing in a cheap thread rolling machine doesn't mean sacrificing quality; instead, it can be a strategic move when done correctly. Here's an insightful exploration based on real-world experiences and professional expertise, providing a trustworthy guide for selecting cost-effective thread rolling machinery.

4. Case Studies from the Field Real-life examples can be quite illuminating. Consider a mid-sized automotive parts manufacturer that reduced operation costs by 30% after integrating a cost-effective rolling machine. Although initially skeptical, they found the machine met their production standards without incurring frequent downtimes. Such success stories underscore the potential of choosing budget-friendly models. 5. Professional Authority and Recommendations Industry veterans recommend partnering with suppliers who have a track record of reliability. They advise against models that seem too good to be true at exceptionally low prices. Instead, focus on those that balance cost with documented performance metrics. Leveraging networks to get peer recommendations can also provide credible insights. 6. Enhancing Trust Through Certifications Another layer of trust can be achieved by verifying machine certifications. Equipment adhering to international standards not only assures compliance but also signifies a commitment to quality. ISO certifications, for instance, are markers of efficiency and reliability. In conclusion, securing a cheap thread rolling machine is about aligning your specific needs with market offerings smartly. It involves understanding the production requirements, focusing on key functional features, and trusting reputable brands and suppliers. With these considerations in mind, businesses can make informed decisions that bolster operational efficiency while staying within budget. Investing time in research and leveraging expert recommendations can facilitate a wise selection, ensuring that affordability aligns seamlessly with quality and durability—proving that cheaper options, when selected wisely, can indeed deliver substantial value.

4. Case Studies from the Field Real-life examples can be quite illuminating. Consider a mid-sized automotive parts manufacturer that reduced operation costs by 30% after integrating a cost-effective rolling machine. Although initially skeptical, they found the machine met their production standards without incurring frequent downtimes. Such success stories underscore the potential of choosing budget-friendly models. 5. Professional Authority and Recommendations Industry veterans recommend partnering with suppliers who have a track record of reliability. They advise against models that seem too good to be true at exceptionally low prices. Instead, focus on those that balance cost with documented performance metrics. Leveraging networks to get peer recommendations can also provide credible insights. 6. Enhancing Trust Through Certifications Another layer of trust can be achieved by verifying machine certifications. Equipment adhering to international standards not only assures compliance but also signifies a commitment to quality. ISO certifications, for instance, are markers of efficiency and reliability. In conclusion, securing a cheap thread rolling machine is about aligning your specific needs with market offerings smartly. It involves understanding the production requirements, focusing on key functional features, and trusting reputable brands and suppliers. With these considerations in mind, businesses can make informed decisions that bolster operational efficiency while staying within budget. Investing time in research and leveraging expert recommendations can facilitate a wise selection, ensuring that affordability aligns seamlessly with quality and durability—proving that cheaper options, when selected wisely, can indeed deliver substantial value.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025