-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

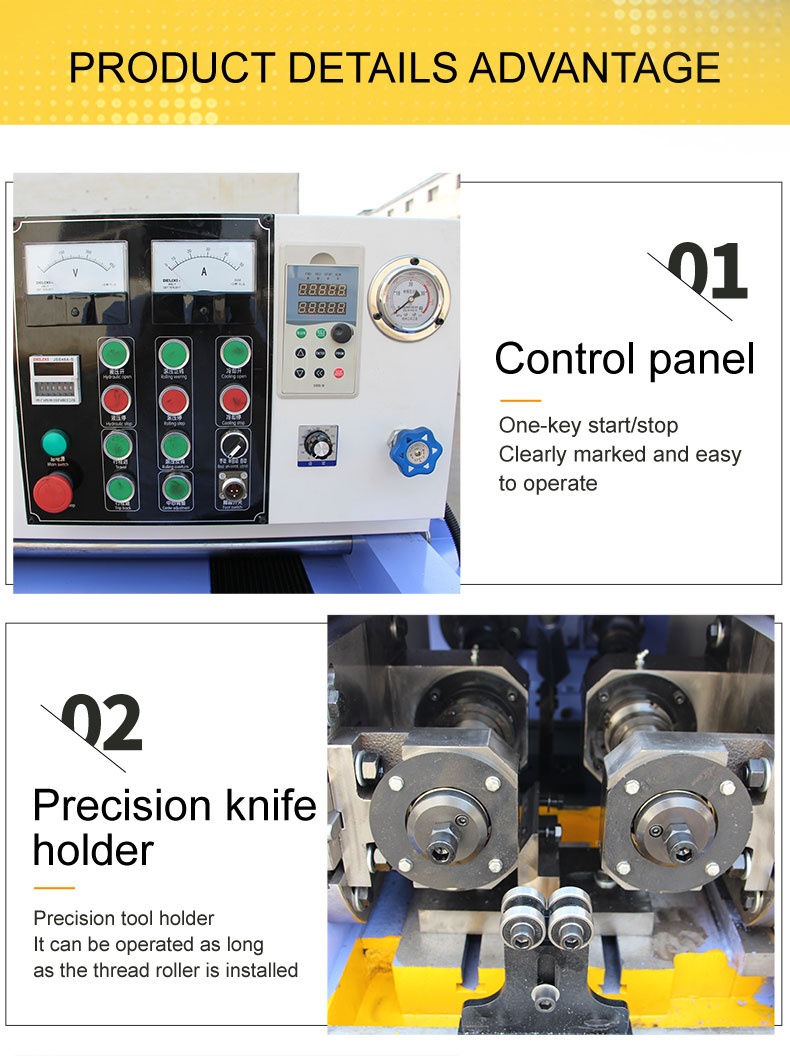

Hydraulic Threading Machines for Efficient and Precise Pipe Connections in China

The Advancements and Importance of Hydraulic Threading Machines in China

In recent years, the manufacturing sector in China has witnessed significant technological advancements, particularly in the field of hydraulic machinery. Among these innovations, hydraulic threading machines have emerged as pivotal tools for various industries, including construction, plumbing, and manufacturing. These machines have revolutionized the way threaded components are produced, offering enhanced efficiency, precision, and versatility.

What is a Hydraulic Threading Machine?

A hydraulic threading machine is specifically designed to create threaded ends on pipes and other metal components. Utilizing hydraulic power, these machines can generate the necessary force to cut threads accurately on a variety of materials, including steel, copper, and PVC. The hydraulic system enables smoother operation and greater force application compared to traditional threading machines, making it an essential equipment in settings where precision is crucial.

Advantages of Hydraulic Threading Machines

1. Precision and Consistency One of the primary advantages of hydraulic threading machines is their ability to produce threads with high precision. The hydraulic system allows for controlled cutting speeds and depths, which results in consistently high-quality threads. This level of precision is critical in industries where the integrity of threaded connections affects overall safety and performance.

2. Efficiency Hydraulic threading machines are designed to operate quickly and efficiently, significantly reducing the time required to produce threaded components. The automation features often found in hydraulic models allow for rapid setup and operation, enabling manufacturers to meet high demand without compromising on quality.

3. Versatility These machines can accommodate a wide range of materials and sizes, making them suitable for various applications. From small diameter pipes to large industrial components, hydraulic threading machines can be adjusted to meet specific project requirements. This versatility makes them invaluable in diverse sectors such as oil and gas, water supply, and construction.

4. Labor Savings The automation and hydraulic mechanisms reduce the physical strain on operators, leading to lower labor costs and increased safety on job sites. Workers can operate these machines with minimal manual intervention, which not only improves productivity but also reduces the risk of workplace injuries associated with manual threading processes.

china hydraulic threading machine

The Role of Chinese Manufacturers

Chinese manufacturers have played a crucial role in the development and production of hydraulic threading machines. The country boasts a robust machinery manufacturing sector, with numerous companies specializing in hydraulic technology. These manufacturers have invested heavily in research and development, leading to innovations that enhance the performance and reliability of threading machines.

Additionally, many Chinese firms have adopted advanced manufacturing techniques, such as computer numerical control (CNC) technology, which further improves the precision of hydraulic threading machines. As a result, China's hydraulic threading machines are increasingly being recognized on a global scale for their quality and innovation.

Challenges and Future Outlook

Despite the advantages, the hydraulic threading machine industry in China faces several challenges. Competition from both domestic and international manufacturers is intensifying, prompting companies to innovate continuously. Furthermore, the fluctuating prices of raw materials can impact production costs and pricing strategies.

Looking ahead, the future of hydraulic threading machines in China appears promising. With ongoing advancements in automation and smart technologies, the industry is likely to see the emergence of more sophisticated machinery. The integration of artificial intelligence and IoT (Internet of Things) will further enhance operational efficiencies and predictive maintenance capabilities.

Conclusion

Hydraulic threading machines represent a significant technological leap within China's manufacturing landscape. Their precision, efficiency, and versatility make them indispensable in various applications, from construction to manufacturing. As Chinese manufacturers continue to innovate and adopt cutting-edge technologies, the hydraulic threading machine industry is poised for growth, ensuring its vital role in meeting both domestic and global market demands. The evolution of these machines not only reflects the advancements in manufacturing technology but also underscores the crucial importance of quality and efficiency in today’s industrial environment.