-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 28, 2024 11:20

Back to list

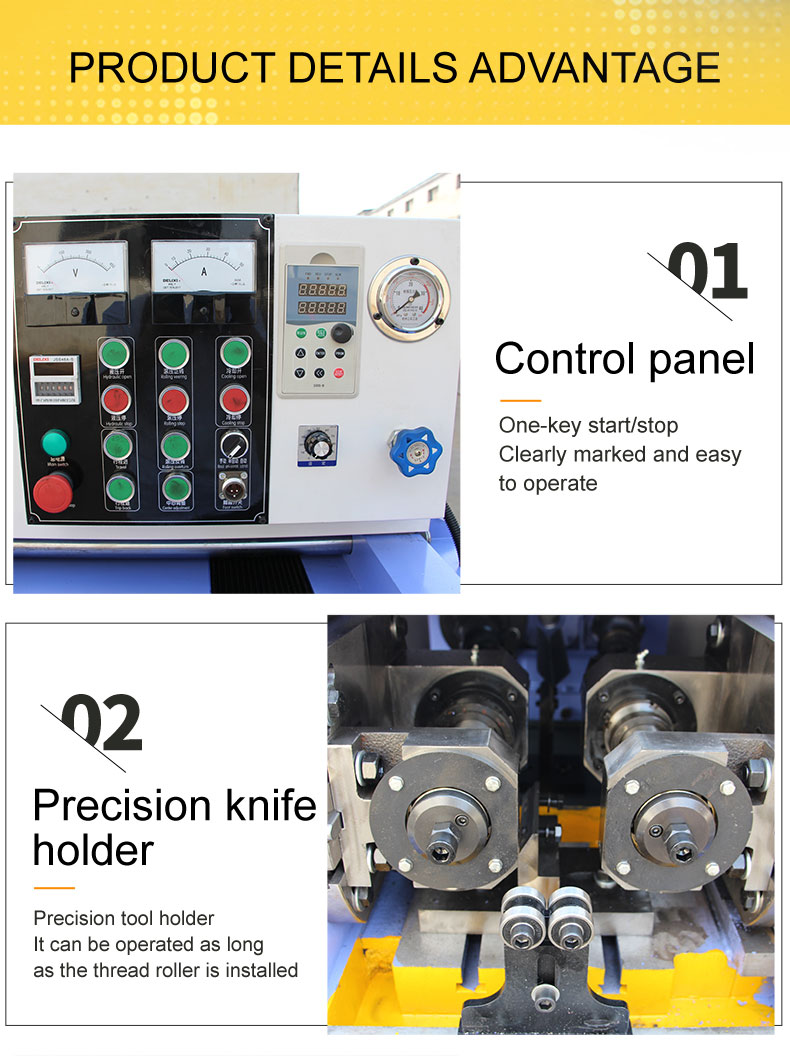

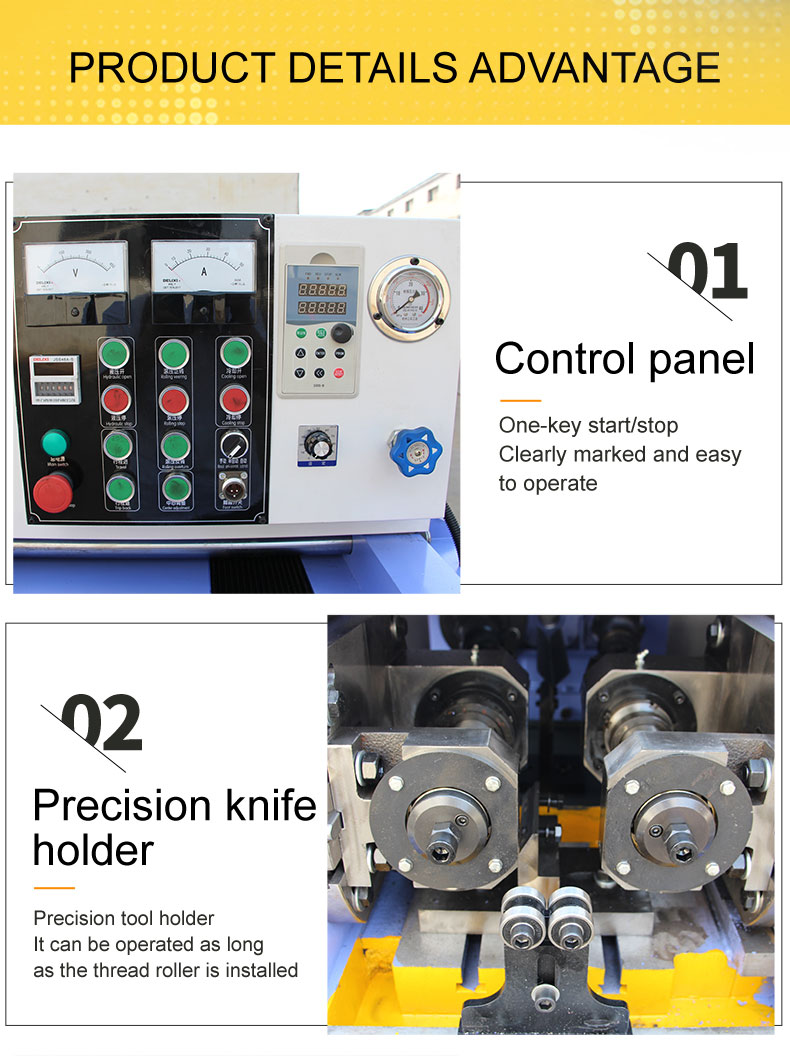

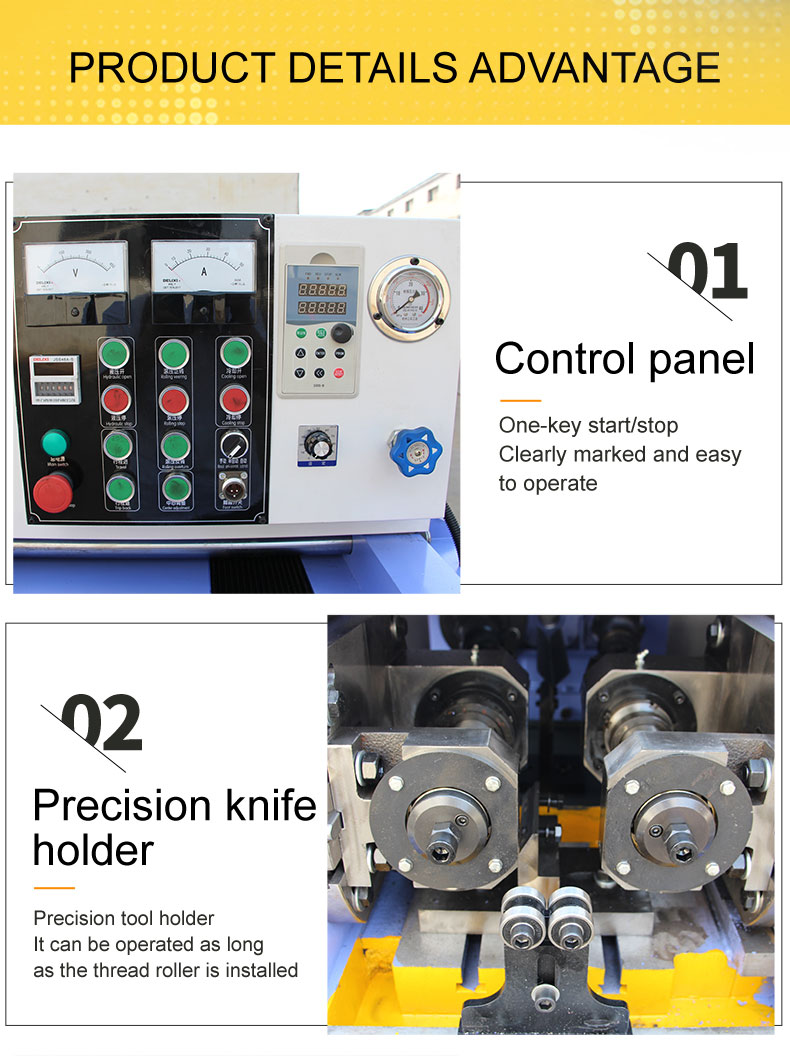

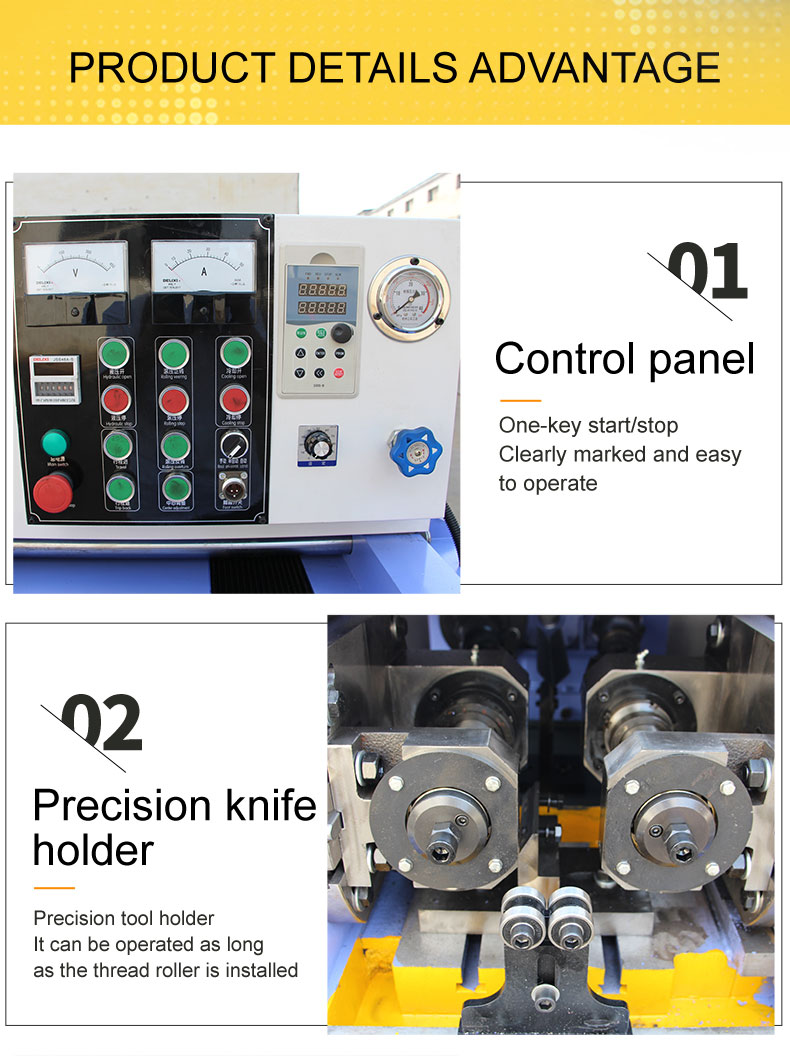

China's No. 3 Die Thread Rolling Machine An Innovative Solution for Precision Manufacturing

Advancements in China's Thread Rolling Machine Technology

The manufacturing sector, especially the metal fabrication industry, is a cornerstone of modern industrial development. In this context, China has made significant strides in the innovation and enhancement of thread rolling machine technology, contributing to its status as a global manufacturing hub. The evolution of these machines, commonly referred to as thread rolling machines or die thread rolling machines, has revolutionized the production process, offering increased efficiency, precision, and cost-effectiveness.

Thread rolling machines are specialized tools designed to form threads on a workpiece without removing any material, unlike cutting or grinding processes. This method is more efficient and produces stronger threads due to the work hardening of the material during the process. As a result, these machines have become essential in various industries, including automotive, aerospace, and fastener manufacturing.

In China, the development of die thread rolling machines has been rapid. With advancements in control systems and mechanical design, Chinese manufacturers have introduced models capable of higher speeds and greater accuracy. These machines often feature CNC (Computer Numerical Control) capabilities, allowing for complex thread formations with minimal human intervention. The automation reduces the potential for human error and increases output consistency.

Furthermore, Chinese engineers have focused on energy efficiency in the design of these machines. By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels

By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels china 3 die thread rolling machine. This commitment to sustainability not only reduces operational costs for businesses but also aligns with global efforts to reduce industrial carbon footprints.

Another area of innovation is the integration of advanced sensors and diagnostic tools. These features enable real-time monitoring of the thread rolling process, ensuring quality control and minimizing defects. Such technological enhancements have made Chinese thread rolling machines highly competitive in the international market, where precision and reliability are paramount.

Despite challenges such as trade barriers and competition from established manufacturing nations, China continues to invest heavily in research and development for thread rolling technologies. Collaborations between universities, research institutions, and private enterprises foster an environment conducive to innovation. As a result, Chinese thread rolling machines are becoming increasingly sophisticated, catering to diverse industrial needs worldwide.

In conclusion, China's progress in thread rolling machine technology underscores its dedication to advancing manufacturing processes. Through continuous innovation, these machines are at the forefront of efficiency, sustainability, and precision. As China looks towards the future, the development of thread rolling machines will undoubtedly remain a key area of focus, promising further advancements that could reshape global manufacturing standards.

china 3 die thread rolling machine. This commitment to sustainability not only reduces operational costs for businesses but also aligns with global efforts to reduce industrial carbon footprints.

Another area of innovation is the integration of advanced sensors and diagnostic tools. These features enable real-time monitoring of the thread rolling process, ensuring quality control and minimizing defects. Such technological enhancements have made Chinese thread rolling machines highly competitive in the international market, where precision and reliability are paramount.

Despite challenges such as trade barriers and competition from established manufacturing nations, China continues to invest heavily in research and development for thread rolling technologies. Collaborations between universities, research institutions, and private enterprises foster an environment conducive to innovation. As a result, Chinese thread rolling machines are becoming increasingly sophisticated, catering to diverse industrial needs worldwide.

In conclusion, China's progress in thread rolling machine technology underscores its dedication to advancing manufacturing processes. Through continuous innovation, these machines are at the forefront of efficiency, sustainability, and precision. As China looks towards the future, the development of thread rolling machines will undoubtedly remain a key area of focus, promising further advancements that could reshape global manufacturing standards.

By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels

By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels By optimizing motor sizes and power usage, newer thread rolling machines consume less energy while maintaining or even improving performance levels china 3 die thread rolling machine. This commitment to sustainability not only reduces operational costs for businesses but also aligns with global efforts to reduce industrial carbon footprints.

Another area of innovation is the integration of advanced sensors and diagnostic tools. These features enable real-time monitoring of the thread rolling process, ensuring quality control and minimizing defects. Such technological enhancements have made Chinese thread rolling machines highly competitive in the international market, where precision and reliability are paramount.

Despite challenges such as trade barriers and competition from established manufacturing nations, China continues to invest heavily in research and development for thread rolling technologies. Collaborations between universities, research institutions, and private enterprises foster an environment conducive to innovation. As a result, Chinese thread rolling machines are becoming increasingly sophisticated, catering to diverse industrial needs worldwide.

In conclusion, China's progress in thread rolling machine technology underscores its dedication to advancing manufacturing processes. Through continuous innovation, these machines are at the forefront of efficiency, sustainability, and precision. As China looks towards the future, the development of thread rolling machines will undoubtedly remain a key area of focus, promising further advancements that could reshape global manufacturing standards.

china 3 die thread rolling machine. This commitment to sustainability not only reduces operational costs for businesses but also aligns with global efforts to reduce industrial carbon footprints.

Another area of innovation is the integration of advanced sensors and diagnostic tools. These features enable real-time monitoring of the thread rolling process, ensuring quality control and minimizing defects. Such technological enhancements have made Chinese thread rolling machines highly competitive in the international market, where precision and reliability are paramount.

Despite challenges such as trade barriers and competition from established manufacturing nations, China continues to invest heavily in research and development for thread rolling technologies. Collaborations between universities, research institutions, and private enterprises foster an environment conducive to innovation. As a result, Chinese thread rolling machines are becoming increasingly sophisticated, catering to diverse industrial needs worldwide.

In conclusion, China's progress in thread rolling machine technology underscores its dedication to advancing manufacturing processes. Through continuous innovation, these machines are at the forefront of efficiency, sustainability, and precision. As China looks towards the future, the development of thread rolling machines will undoubtedly remain a key area of focus, promising further advancements that could reshape global manufacturing standards. Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025