-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

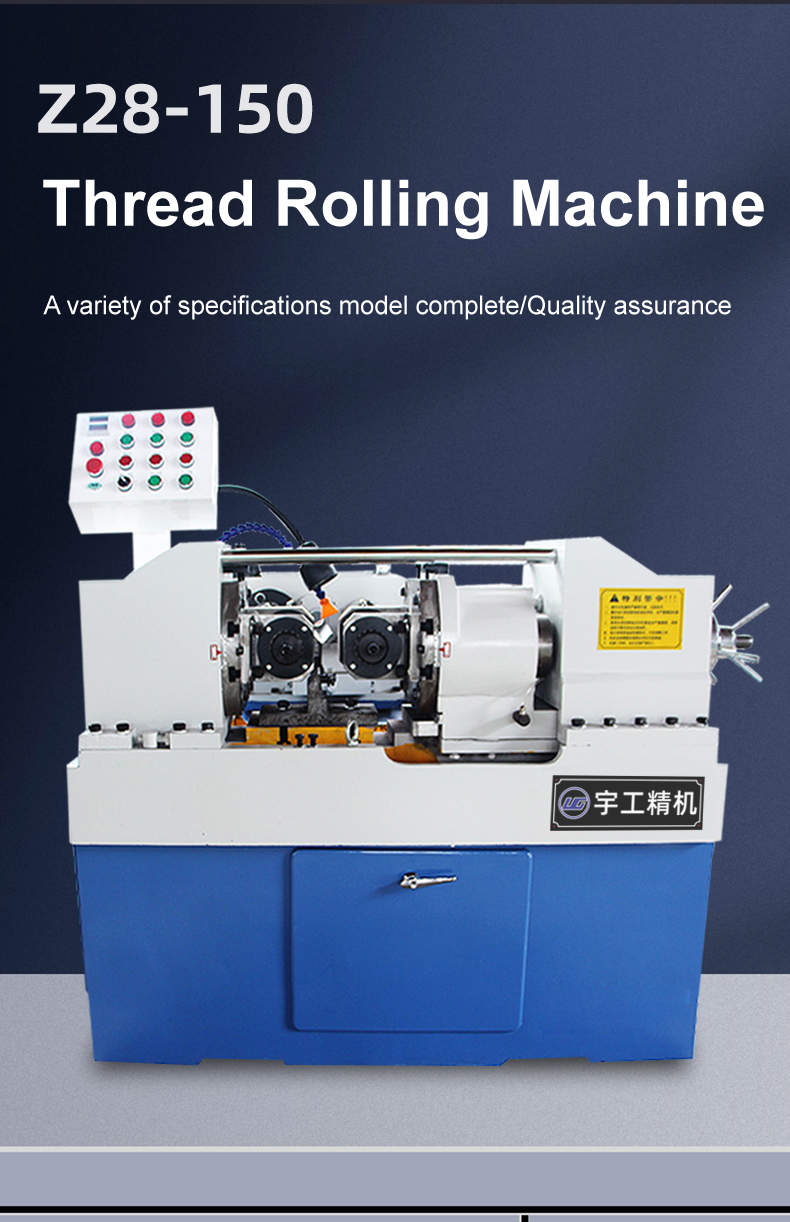

china screw rolling machine

The Versatility and Efficiency of China Screw Rolling Machines

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. One of the crucial components of this efficiency is the machinery employed in the production process. Among these tools, the screw rolling machine stands out as a significant asset, particularly in China, where manufacturing capabilities are continually advancing.

Screw rolling machines are specialized equipment used to manufacture screws and other fasteners through a rolling process. This machine reshapes metal into precise thread forms, providing a cost-effective and efficient alternative to traditional machining methods. The advantages of using a screw rolling machine are numerous, ranging from reduced material waste to enhanced production speed.

The Versatility and Efficiency of China Screw Rolling Machines

Chinese manufacturers have invested heavily in the development of advanced screw rolling technology. The integration of automation and modern control systems into screw rolling machines has revolutionized their operation. These machines can now produce a larger volume of screws in a shorter amount of time, meeting the growing demand from various sectors. Automation reduces labor costs and the likelihood of human error, further enhancing overall production effectiveness.

china screw rolling machine

Moreover, screw rolling machines in China are designed to accommodate a wide range of materials. Whether it is carbon steel, stainless steel, or alloy materials, these machines can handle different alloys with ease, making them versatile for various manufacturing needs. This adaptability is particularly advantageous when manufacturers require a quick switch in production to address market demands or to develop new products.

Environmental concerns are also driving the evolution of screw rolling machines in China. Traditional machining processes are often associated with higher levels of waste and energy consumption. In contrast, the screw rolling process generates significantly less scrap material, which makes it a more sustainable option. Many manufacturers are leaning toward eco-friendly practices, and the adoption of efficient screw rolling machinery aligns well with these sustainability goals.

Furthermore, the aftermarket support and service for screw rolling machines are thriving in China. With a strong manufacturing ecosystem, companies offer comprehensive services, including machine maintenance, upgrades, and training for operators. This ensures that businesses can maximize their investment in screw rolling technology, minimizing downtime and enhancing productivity.

In conclusion, the screw rolling machine represents a pivotal advancement in manufacturing technology, particularly within China's dynamic industrial landscape. With its high precision, material efficiency, adaptability to various materials, and sustainability benefits, it is no wonder that many manufacturers are integrating these machines into their production lines. As the demand for fasteners continues to rise, the screw rolling machine stands out as a critical tool, driving innovation and efficiency in the global manufacturing arena. With ongoing advancements, we are likely to see even more significant developments in this field in the years to come.