-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 08, 2025 07:40

Back to list

china types of thread rolling

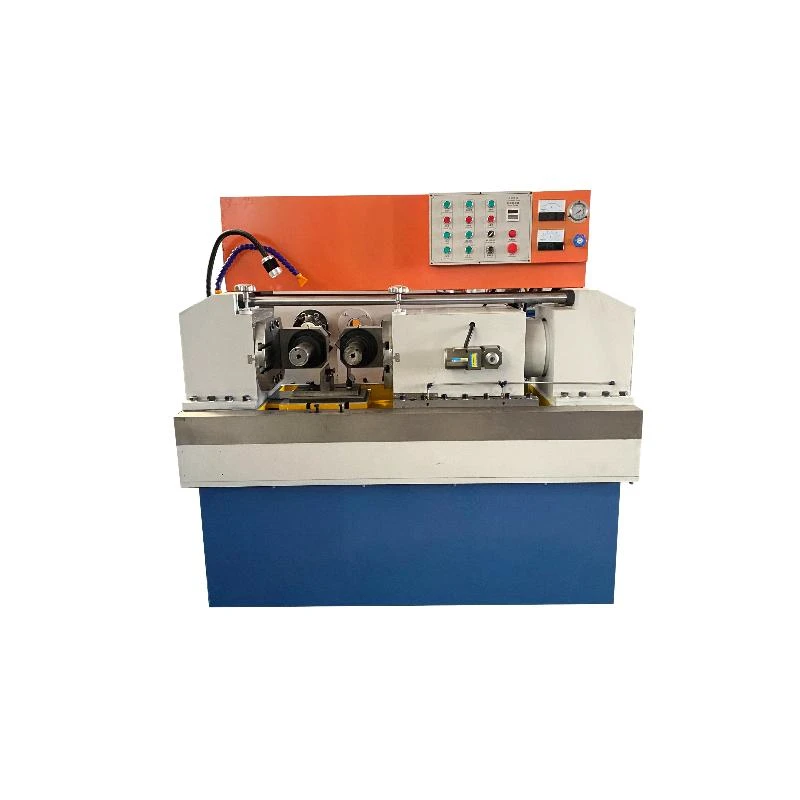

China has emerged as a significant player in the manufacturing sector, with thread rolling techniques being a critical component in its industrial prowess. Thread rolling is a cold forging process that allows for mass production of high-quality threaded components. It is an advantageous alternative to traditional thread cutting due to the superiority of its mechanical properties and material conservation. Understanding the different types of thread rolling processes employed in China can provide businesses with essential insights into efficiency and quality improvements.

Quality Assurance and Enhancements In China, the emphasis on quality assurance in thread rolling is paramount. Sophisticated inspection systems are integrated into the production line to ensure that each component meets the required specifications. Non-destructive testing (NDT) techniques such as eddy current testing and ultrasonic inspection are widely employed to detect any subsurface anomalies. Additionally, China’s adherence to international standards such as ISO and DIN ensures that thread rolled products are competitive on a global scale. The Role of Technological Advancements Recent technological advancements have further refined the thread rolling process in China. CNC-controlled thread rolling machines offer unparalleled precision and repeatability. Incorporating real-time data collection and monitoring systems has improved process efficiency and decreased downtime. Innovations in materials, including the use of high-performance alloys, have allowed for the production of components that can withstand extreme environmental conditions, expanding the applicability of thread rolling in advanced industrial sectors. Sustainability Considerations Thread rolling is inherently more sustainable than traditional thread cutting methods, as it does not generate waste chips. China’s focus on sustainability has led to the adoption of energy-efficient machinery and processes in thread rolling. Many manufacturers are switching to eco-friendly lubricants and are implementing comprehensive recycling programs for unused materials to minimize the environmental footprint. Conclusion China's expertise in various thread rolling techniques represents a blend of traditional methods and modern engineering capabilities. The country's focus on innovation, quality assurance, and sustainability ensures that thread rolled products meet the demanding specifications of international markets. Businesses looking to source thread rolled components can benefit from China’s advanced manufacturing techniques, which are backed by robust quality control and global standards adherence. Whether it is through flat die, planetary die, or two-die cylindrical thread rolling, China provides reliable and high-quality solutions tailored to diverse industrial needs.

Quality Assurance and Enhancements In China, the emphasis on quality assurance in thread rolling is paramount. Sophisticated inspection systems are integrated into the production line to ensure that each component meets the required specifications. Non-destructive testing (NDT) techniques such as eddy current testing and ultrasonic inspection are widely employed to detect any subsurface anomalies. Additionally, China’s adherence to international standards such as ISO and DIN ensures that thread rolled products are competitive on a global scale. The Role of Technological Advancements Recent technological advancements have further refined the thread rolling process in China. CNC-controlled thread rolling machines offer unparalleled precision and repeatability. Incorporating real-time data collection and monitoring systems has improved process efficiency and decreased downtime. Innovations in materials, including the use of high-performance alloys, have allowed for the production of components that can withstand extreme environmental conditions, expanding the applicability of thread rolling in advanced industrial sectors. Sustainability Considerations Thread rolling is inherently more sustainable than traditional thread cutting methods, as it does not generate waste chips. China’s focus on sustainability has led to the adoption of energy-efficient machinery and processes in thread rolling. Many manufacturers are switching to eco-friendly lubricants and are implementing comprehensive recycling programs for unused materials to minimize the environmental footprint. Conclusion China's expertise in various thread rolling techniques represents a blend of traditional methods and modern engineering capabilities. The country's focus on innovation, quality assurance, and sustainability ensures that thread rolled products meet the demanding specifications of international markets. Businesses looking to source thread rolled components can benefit from China’s advanced manufacturing techniques, which are backed by robust quality control and global standards adherence. Whether it is through flat die, planetary die, or two-die cylindrical thread rolling, China provides reliable and high-quality solutions tailored to diverse industrial needs.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025