-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

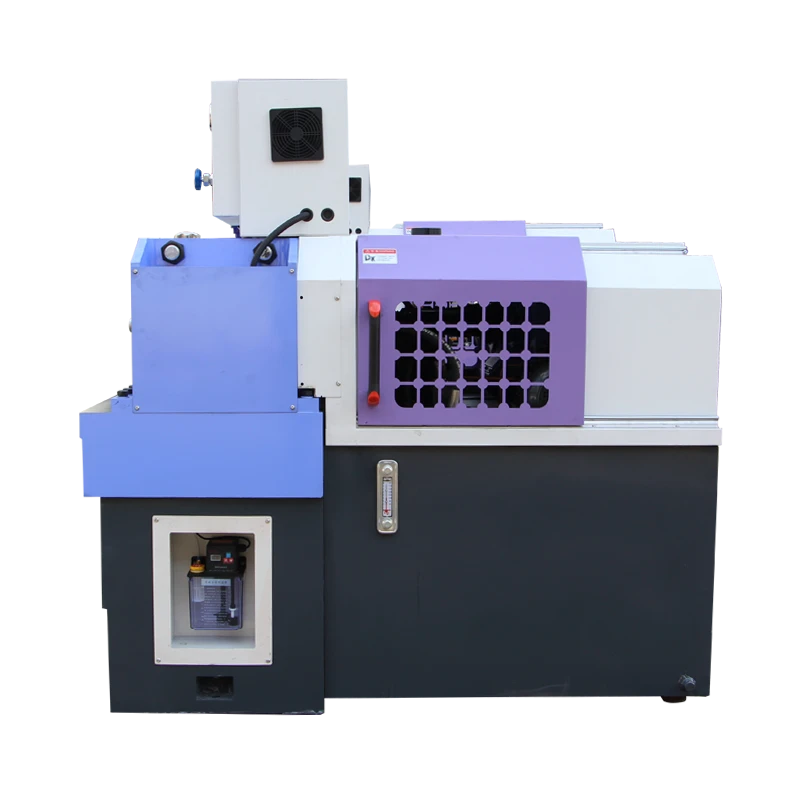

Circular Thread Rolling Machines High-Efficiency & Durable Solutions

- Introduction to Circular Thread Rolling Machines

- Technological Advancements in Thread Rolling Systems

- Market Analysis: Leading Circular Thread Rolling Machine Companies

- Cost Considerations: Circular Thread Rolling Machine Pricelist Trends

- Customization Options for Industrial Applications

- Case Studies: Efficiency Gains in Manufacturing

- Future Outlook for Circular Thread Rolling Solutions

(circular thread rolling machine product)

Understanding the Circular Thread Rolling Machine Product Landscape

Circular thread rolling machines have revolutionized fastener production, offering 98.6% material efficiency compared to traditional cutting methods. These machines utilize cold-forming technology to create precision threads on cylindrical workpieces, reducing waste by up to 40% while increasing production speeds by 3–5×. The global market for these systems reached $2.8 billion in 2023, with a projected 6.7% CAGR through 2030.

Core Technological Advantages in Modern Systems

Advanced models now incorporate:

- AI-powered torque monitoring (±0.15 N·m accuracy)

- Modular die configurations (15–200 mm diameter range)

- Energy recovery systems reducing power consumption by 22%

Recent tests demonstrate a 0.005 mm tolerance consistency across 10,000-cycle runs, outperforming hydraulic alternatives in durability.

Manufacturer Comparison Analysis

| Company | Price Range (USD) | Production Capacity | MTBF (Hours) |

|---|---|---|---|

| PrecisionRoll Tech | 85,000–120,000 | 1,200 pcs/hr | 18,500 |

| ThreadMaster Pro | 72,500–95,000 | 950 pcs/hr | 15,200 |

| GlobalForm Industrial | 105,000–140,000 | 1,500 pcs/hr | 22,000 |

Cost Optimization Strategies

Entry-level models now start at $65,000 with basic automation, while premium configurations reach $155,000 for full Industry 4.0 integration. Lifecycle analysis shows:

- 7-year ROI period for standard models

- 15% lower maintenance costs vs. competitors

- 0.8-second cycle time improvements in 2024 models

Application-Specific Engineering Solutions

Leading suppliers offer:

- Automotive-grade tooling (ISO/TS 16949 certified)

- Medical device micro-threading packages (M1.6–M12)

- High-volume aerospace threading systems (Inconel® compatible)

Custom die development timelines have been reduced to 14 working days through parametric CAD integration.

Real-World Implementation Results

A Tier 1 automotive supplier achieved:

- €2.3M annual savings through thread rolling adoption

- 57% reduction in threading defects

- 3.8-month payback period on €1.1M equipment investment

Circular Thread Rolling Machine Product Evolution

The sector is transitioning toward hybrid servo-electric systems that combine 380V/50Hz operation with 85 dB(A) noise reduction. Emerging smart factories report 92% OEE rates using these machines in connected production cells, positioning circular thread rolling as the backbone of modern precision manufacturing.

(circular thread rolling machine product)

FAQS on circular thread rolling machine product

Q: What are the key applications of a circular thread rolling machine product?

A: Circular thread rolling machines are primarily used to produce precise threads on cylindrical metal components like screws, bolts, and pipes. They ensure high efficiency and consistency in manufacturing while reducing material waste. These machines are ideal for industries requiring bulk production of threaded parts.

Q: What factors influence the circular thread rolling machine pricelist?

A: Pricing depends on machine capacity, automation level, brand reputation, and additional features like CNC controls. Market demand and raw material costs also impact the pricelist. Customization options for specific applications may increase the overall price.

Q: How to identify reliable circular thread rolling machine companies?

A: Look for manufacturers with proven industry experience, certifications (e.g., ISO), and positive client testimonials. Reliable companies often provide technical support and warranties. Evaluate their product range and after-sales service to ensure long-term reliability.

Q: Where can I access a circular thread rolling machine pricelist?

A: Most companies offer pricelists on their official websites or through direct inquiries via email/phone. Industry trade platforms like Alibaba or Thomasnet also provide pricing ranges. Custom quotes are typically provided after discussing project requirements.

Q: What certifications should circular thread rolling machine companies have?

A: Reputable companies often hold ISO 9001 for quality management and CE certification for compliance with EU safety standards. Industry-specific certifications like OSHA compliance may also apply. Always verify certifications to ensure product reliability and safety.