-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

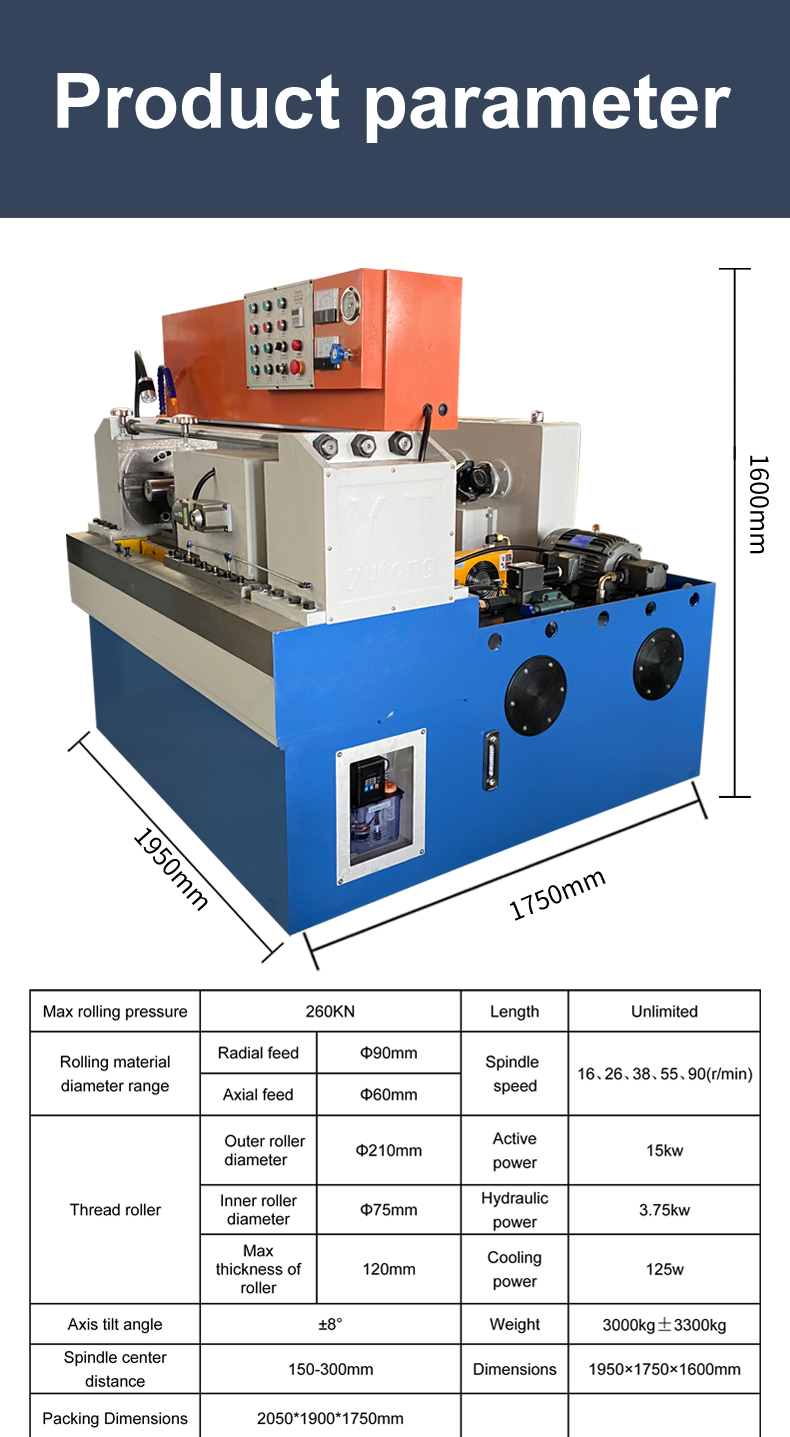

Circular Thread Rolling Machine Manufacturer for Precision Machinery Solutions

The Advancements in Circular Thread Rolling Machine Manufacturing

In the realm of precision engineering and fabrication, circular thread rolling machines stand out as vital tools for producing high-quality threaded components. These machines have become indispensable in various industries, ranging from automotive to aerospace, due to their ability to create strong, consistent threads on metal workpieces. As the demand for efficient and precise manufacturing processes grows, so does the need for innovative factories specializing in the production of these advanced machines.

The Advancements in Circular Thread Rolling Machine Manufacturing

Moreover, the manufacturing processes employed in circular thread rolling machine factories have evolved dramatically. Automation, advanced computer numerical control (CNC) systems, and state-of-the-art robotics have streamlined operations, increasing productivity while maintaining exceptional quality standards. These technological advancements enable factories to produce machines that can handle a wide range of materials, from soft aluminum alloys to hard steel, thus catering to a diverse client base.

circular thread rolling machine factory

A key focus in these factories is the precision of the machines themselves. High-quality dies, which are crucial for the thread rolling process, are engineered to ensure exacting tolerances. Advanced materials such as carbide and high-speed steel are often used to manufacture dies that can withstand the rigors of production. Additionally, incorporating sophisticated software for die design and simulation allows for optimization before physical production begins, reducing waste and enhancing efficiency.

Moreover, sustainability has become an essential consideration in the design and operation of circular thread rolling machine factories. Manufacturers are increasingly adopting eco-friendly practices, such as using energy-efficient machines, optimizing material usage, and implementing recycling programs for metal shavings and other byproducts. These initiatives not only reduce the environmental footprint but also align with the growing market demand for sustainable production methods.

Employee training and expertise are paramount in ensuring the operational efficiency of thread rolling machine factories. Skilled labor is necessary to oversee intricate machine operations, troubleshoot problems, and ensure maintenance is performed correctly. Continuous training programs help keep personnel updated on the latest technologies and best practices, fostering a culture of innovation and excellence within the workforce.

In conclusion, circular thread rolling machine factories play a crucial role in modern manufacturing. Through the integration of advanced technologies, sustainable practices, and a commitment to quality, these facilities are not only meeting the current demands of various industries but are also paving the way for future innovations. As the industry continues to evolve, the impact of these machines will undoubtedly expand, solidifying their position as essential tools in achieving precision and reliability in component manufacturing.