-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

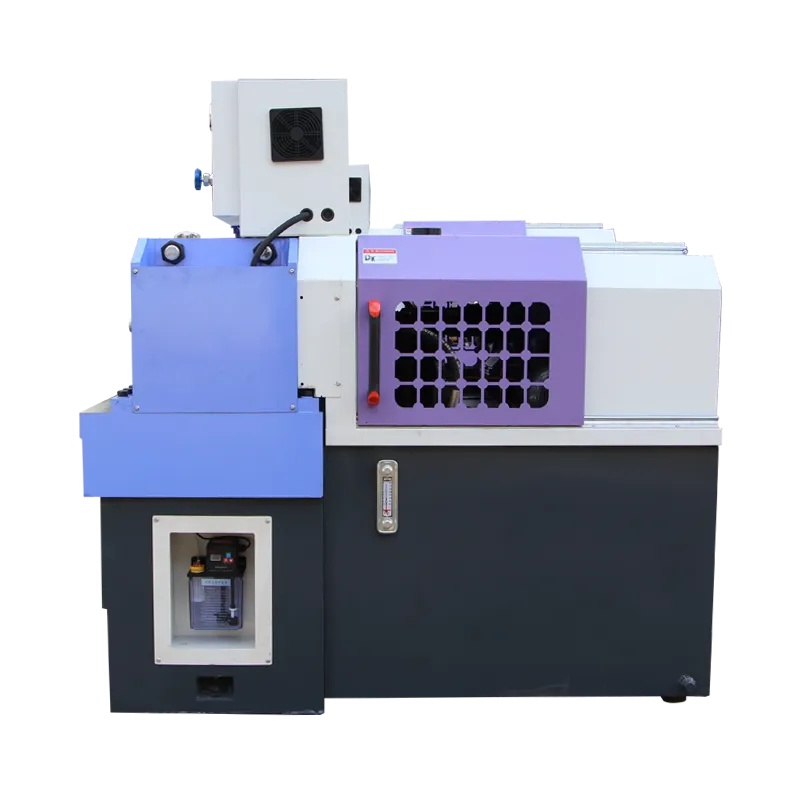

Premium CNC Thread Rolling Machine Factory High-Precision Manufacturing

- Introduction to CNC thread processing technology

- Technical superiority in modern thread rolling equipment

- Comparative analysis of leading manufacturers

- Customization capabilities for specific industrial requirements

- Real-world application scenarios across multiple industries

- Cost-benefit assessment and production impact

- Selecting the ideal manufacturing partner for reliability

(cnc thread rolling machine factory)

Unveiling Precision Engineering in Thread Fabrication

Contemporary manufacturing relies on specialized equipment for producing high-tolerance threaded components. Advanced cold-forming techniques employed by industrial suppliers transform raw materials into precision parts with exceptional dimensional consistency. This technology demonstrates particular advantages when processing hardened steels, aerospace alloys, and medical-grade materials where thread integrity directly impacts product safety and performance.

Rolling specialists optimize cycle times to 4-8 seconds per component depending on thread complexity, significantly outperforming traditional machining. Material savings range between 15-25% since no waste chips are generated during the cold-forming process. Industry-certified facilities follow ISO 9001 standards throughout production, ensuring uniform quality across batches.

Technical Excellence in Thread Formation Equipment

Fourth-generation CNC rolling units incorporate servo-controlled radial infeed mechanisms achieving accuracies within ±0.005mm. Integrated measurement systems automatically compensate for tool wear using real-time feedback loops, maintaining consistency through extended production runs. Automated lubrication dispensers optimize lubricant delivery while connected coolant management systems extend perishable tool life by 30-40%.

Processing capabilities now reach diameters of 0.5mm to 80mm with new linear motor systems enabling production speeds previously unattainable. For stainless steel M6 fasteners, modern equipment demonstrates 20% higher output compared to earlier hydraulic models. Intelligent servo technology permits thread profiles that conventional machining cannot produce cost-effectively, including complex medical implants requiring surface roughness below Ra 0.2μm.

Market Comparison of Industrial Equipment Producers

| Supplier Features | High-Precision Units | Standard Industrial Models | Hybrid Solutions |

|---|---|---|---|

| Maximum Diameter Capacity | 50mm | 80mm | 65mm |

| Production Speed (parts/min) | 18 | 12 | 15 |

| Accuracy Tolerance | ±0.002mm | ±0.01mm | ±0.005mm |

| Automation Integration | Industry 4.0 Protocols | Basic PLC | IoT Connectivity |

| Energy Consumption (kW/h) | 16 | 24 | 20 |

The table illustrates capability variations between three distinct equipment categories. Suppliers offering high-precision configurations prioritize micro-fine accuracy rather than volume throughput, while industrial manufacturers emphasize component size versatility.

Project-Specific Engineering Solutions

Specialized equipment manufacturers develop purpose-built configurations for unique manufacturing challenges. Adaptable systems permit modification of roll tooling diameters, pressure optimization for unusual alloys, and integration with secondary processing stations. Aerospace fastener producers particularly benefit from systems producing NAS-approved threads in heat-resistant superalloys, with equipment calibration maintaining accuracy at operating temperatures exceeding 700°C.

Medical implant specialists utilize small-diameter equipment with ISO Class 7 cleanliness protocols to achieve the necessary surface integrity. For these critical applications, customized monitoring systems track over 20 process parameters simultaneously, storing data for traceability requirements. These technical accommodations permit automotive suppliers to implement on-demand threading solutions reducing inventory overheads by 15-30%.

Implementation Across Industrial Segments

Over 75% of new automobiles contain suspension components processed on computer-controlled rolling equipment. This manufacturing approach significantly enhances fatigue resistance, particularly important for safety-critical elements. Electronics manufacturers employ smaller desktop machines producing threaded brass inserts for circuit boards at tolerances meeting IPC specifications.

Petrochemical operations demonstrate substantial cost benefits when adopting custom-configured machines. Production yield for corrosion-resistant pipeline connectors approaches 99.6% versus traditional machining methods. The hydraulic industry similarly benefits from processing capabilities generating leak-proof fluid ports without secondary sealing treatments.

Operational Economics and Productivity Metrics

Industrial assessments consistently indicate 60-70% cost reductions per threaded component when switching from machining to cold-forming methods. This advantage stems from reduced material needs plus labor savings achieved through automation. Facilities report a typical amortization period of 14-18 months based on three-shift operations. Production managers highlight how modular designs minimize non-productive downtime, accomplishing tool changeovers in under 8 minutes.

Energy efficiency measurements show modern computer-controlled machines consume 35% less electricity than hydraulic predecessors while generating higher output volumes. When environmental compliance factors enter calculations, new electrically powered machines produce significantly less waste coolant than previous generations, reducing disposal expenses. Analysis of operational expenditures reveals maintenance constitutes only 3-5% of lifetime ownership costs for premium systems.

Critical Selection Factors for Manufacturing Equipment Partners

Industrial procurement professionals emphasize comprehensive verification protocols when identifying production solutions. Detailed qualification includes examination of design validation documentation plus rigorous material certifications. Leading facilities maintain dedicated application engineering departments to translate customer requirements into customized equipment specifications.

Responsible equipment manufacturers establish long-term reliability commitments through comprehensive support networks. Maintenance agreements incorporating real-time diagnostics minimize potential interruptions with 95% of component repairs resolved remotely. This support structure becomes particularly valuable when international operations require coordinated global technical assistance.

(cnc thread rolling machine factory)

FAQS on cnc thread rolling machine factory

以下是根据要求创建的5组英文FAQs问答,使用HTML富文本形式:Q: Where can I find a reliable CNC thread rolling machine factory?

A: Our manufacturing plants in industrial zones house state-of-the-art CNC machining centers. All factories maintain ISO 9001 certification and offer onsite technical support. Production facilities are strategically located near major seaports for efficient global distribution.

Q: What distinguishes your cnc thread rolling machine company from competitors?

A: We integrate AI-driven quality control systems and IoT-enabled predictive maintenance. Our patented rolling head technology ensures ±0.005mm precision consistently. Every machine undergoes 72-hour continuous stress testing before shipment.

Q: Can cnc thread rolling machine suppliers provide custom thread profiles?

A: Yes, we engineer specialized dies for unique thread forms like trapezoidal or multi-start threads. Our R&D department uses 3D simulation software to prototype custom profiles. Customization requests typically have 15-day turnaround from design approval.

Q: What materials can your CNC thread rolling machines process?

A: Our equipment handles materials from soft aluminum alloys to hardened steels up to 60 HRC. Dual-pressure hydraulic systems adapt to material hardness variations. Specialized machines are available for exotic metals like Inconel and titanium.

Q: Do you provide technical training for CNC thread rolling machine operators?

A: Comprehensive training programs include hands-on machine operation and CNC programming. Certified trainers conduct sessions at your facility or our training centers. All trainees receive detailed operation manuals and troubleshooting guides.