-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

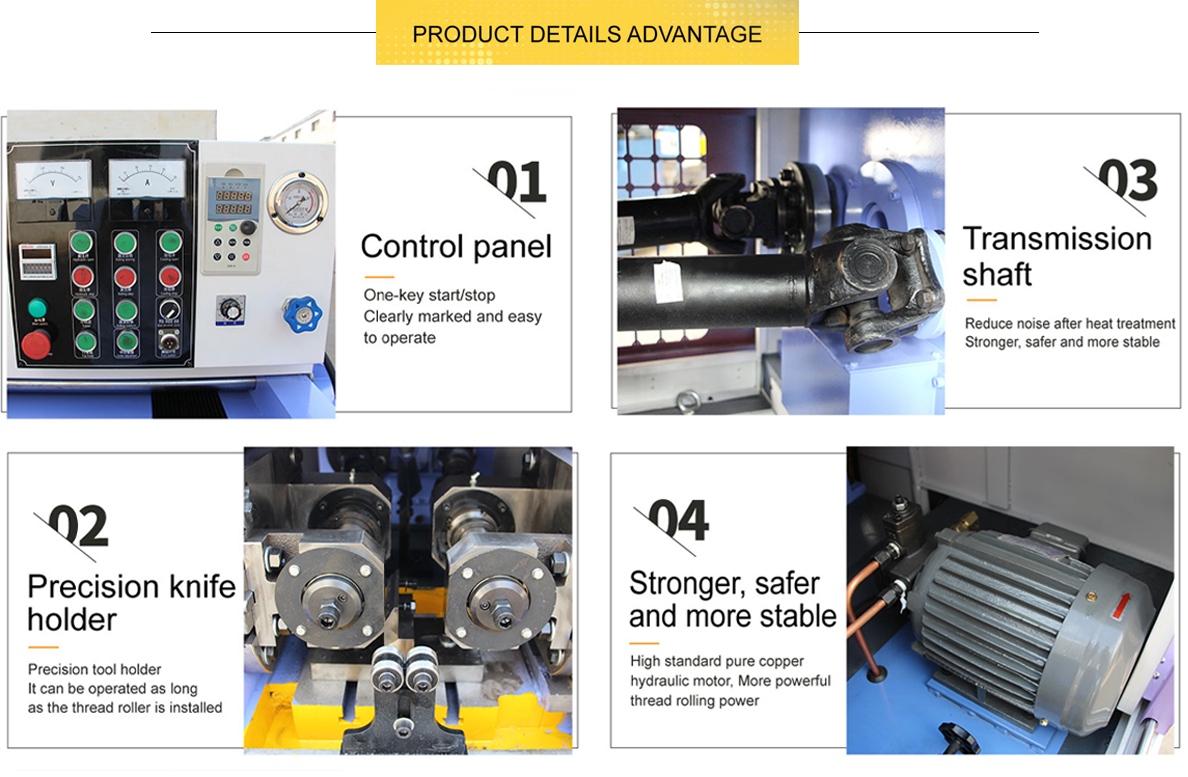

CNC Thread Rolling Machine for Efficient and Precise Metal Thread Production

The Importance of CNC Thread Rolling Machines in Modern Manufacturing

In today’s manufacturing landscape, precision, efficiency, and quality are paramount. Among the various techniques employed to achieve these goals, CNC (Computer Numerical Control) thread rolling machines stand out as a crucial innovation. These machines are essential for producing high-quality threaded components used in numerous industries, including automotive, aerospace, and mechanical engineering.

What is CNC Thread Rolling?

CNC thread rolling is a cold-forming process that creates threads on a workpiece by deforming the material rather than removing it, as in traditional machining methods. This process is known for producing highly accurate threads with improved mechanical properties. The CNC thread rolling machine utilizes computer controls to manage the rolling process, enabling manufacturers to produce complex thread profiles with high precision.

The technology involves two or three cylindrical dies that compress the material into the desired shape as it is passed through the machine. The result is a smooth surface finish with superior strength since the process increases the density of the material without cutting it away.

Benefits of CNC Thread Rolling Machines

1. Enhanced Strength and Durability Since the process is performed at room temperature, the inherent molecular structure of the material remains intact, leading to threads that are not only more durable but also fatigue-resistant. This is particularly important in applications where parts are subject to significant stress and strain.

2. High Precision and Consistency CNC technology allows for precise control over the parameters of the thread-rolling process. This results in exceptional consistency between parts, which is critical for applications that require exact specifications, such as aerospace components or precision machinery.

cnc thread rolling machine

3. Increased Production Speed CNC thread rolling machines can operate at high speeds while maintaining accuracy, significantly improving production capacity. This efficiency can lead to reduced lead times and lower costs for manufacturers.

4. Material Efficiency Unlike traditional cutting methods, thread rolling generates little to no waste since it does not remove material but rather deforms it. This not only saves on raw material costs but also minimizes the environmental impact of the manufacturing process.

5. Versatility CNC thread rolling machines are adaptable and can handle various materials including steel, aluminum, brass, and special alloys. This versatility makes them suitable for a wide range of applications, from simple to complex threaded designs.

Applications of CNC Thread Rolling Machines

CNC thread rolling machines find applications in diverse fields. In the automotive industry, they are essential for producing high-strength bolts, studs, and fasteners that ensure vehicle safety and performance. The aerospace sector relies on precision threaded components that meet strict regulatory standards, where even the smallest deviation can lead to catastrophic failures.

Moreover, in industrial machinery, manufacturers utilize these machines to produce components that endure significant loads and require precise fits. Additionally, the medical device industry has also adopted CNC thread rolling for producing implants and surgical instruments that necessitate high reliability and strength.

Conclusion

The CNC thread rolling machine represents a significant advancement in manufacturing technology. Its ability to produce high-quality threaded components with enhanced strength, precision, and efficiency has made it indispensable across various industries. As manufacturers continue to seek innovative solutions to improve productivity and quality, CNC thread rolling machines will undoubtedly play a pivotal role in shaping the future of manufacturing. Their versatility and effectiveness not only address current market demands but also pave the way for new opportunities in design and application. Embracing this technology is essential for any manufacturer aiming to remain competitive in an ever-evolving industry landscape.