-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Custom CNC Thread Rolling Machine Manufacturer

Custom CNC Thread Rolling Machine Precision Engineering for Optimal Performance

In the realm of modern manufacturing, precision and efficiency are paramount. One of the standout technologies enabling these attributes in metalworking is the custom CNC thread rolling machine. This innovative equipment is designed to meet specific production requirements, offering tailored solutions for a variety of industries, including automotive, aerospace, and electronics.

The Technology Behind CNC Thread Rolling Machines

CNC, or Computer Numerical Control, refers to the automation of machine tools through the use of computers. In thread rolling, this technology allows for the precise shaping of threads on cylindrical metal components through the application of pressure rather than cutting. The process enhances mechanical properties such as tensile strength and fatigue resistance, making it superior to traditional threading methods.

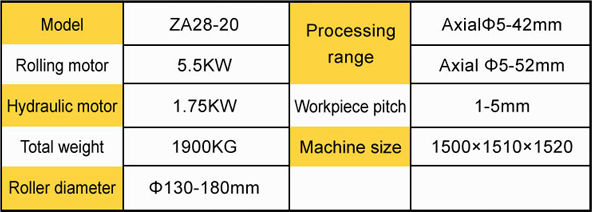

A custom CNC thread rolling machine is specifically designed to accommodate unique specifications of clients. This adaptability enables manufacturers to produce threads of various sizes, shapes, and materials according to the demands of their projects. Whether it is fine threads for delicate applications or coarse threads for heavy-duty parts, a custom solution ensures that the machine operates within the desired parameters.

Advantages of Custom CNC Thread Rolling Machines

1. Increased Efficiency By automating the process, CNC thread rolling machines significantly reduce lead times. High-speed production means that manufacturers can meet tight deadlines while maintaining high standards of quality.

2. Enhanced Precision CNC technology allows for intricate designs and specifications to be met with exceptional accuracy. With advanced software and control systems, manufacturers can achieve tolerances that are difficult to replicate using traditional methods.

custom cnc thread rolling machine

3. Cost-effectiveness While the initial investment in a custom machine may be higher, the longevity and durability of thread rolling machines, combined with reduced material waste, often result in lower total operational costs.

4. Versatility Custom CNC thread rolling machines can handle a wide range of materials, from soft metals like aluminum to harder materials like high-strength stainless steel. This versatility makes them an asset for companies with diverse product lines.

5. Eco-friendly Production Thread rolling is a more sustainable method of producing threads as it generates less scrap material compared to cutting methods. The compacting of material also fosters improved mechanical properties, contributing to longer-lasting products.

Applications in Various Industries

The applications of custom CNC thread rolling machines are extensive. In the automotive industry, these machines are crucial for producing bolts, nuts, and various fasteners that ensure vehicles operate safely and efficiently. The aerospace sector benefits equally, where precision parts are vital to the structural integrity of aircraft. Additionally, in electronics manufacturing, thread rolling machines play a pivotal role in creating components that require finely detailed threading for seamless assembly.

Conclusion

Custom CNC thread rolling machines represent the pinnacle of modern engineering, providing tailored solutions that enhance production processes across various industries. Their ability to increase efficiency, precision, and versatility while being environmentally friendly makes them an invaluable addition to any manufacturing setup. As industries continue to evolve, the demand for tailored machining solutions like CNC thread rolling will likely increase, driving innovation and excellence in manufacturing practices. Embracing this technology not only positions businesses for success but also underscores a commitment to quality and sustainability in an ever-competitive market.