-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

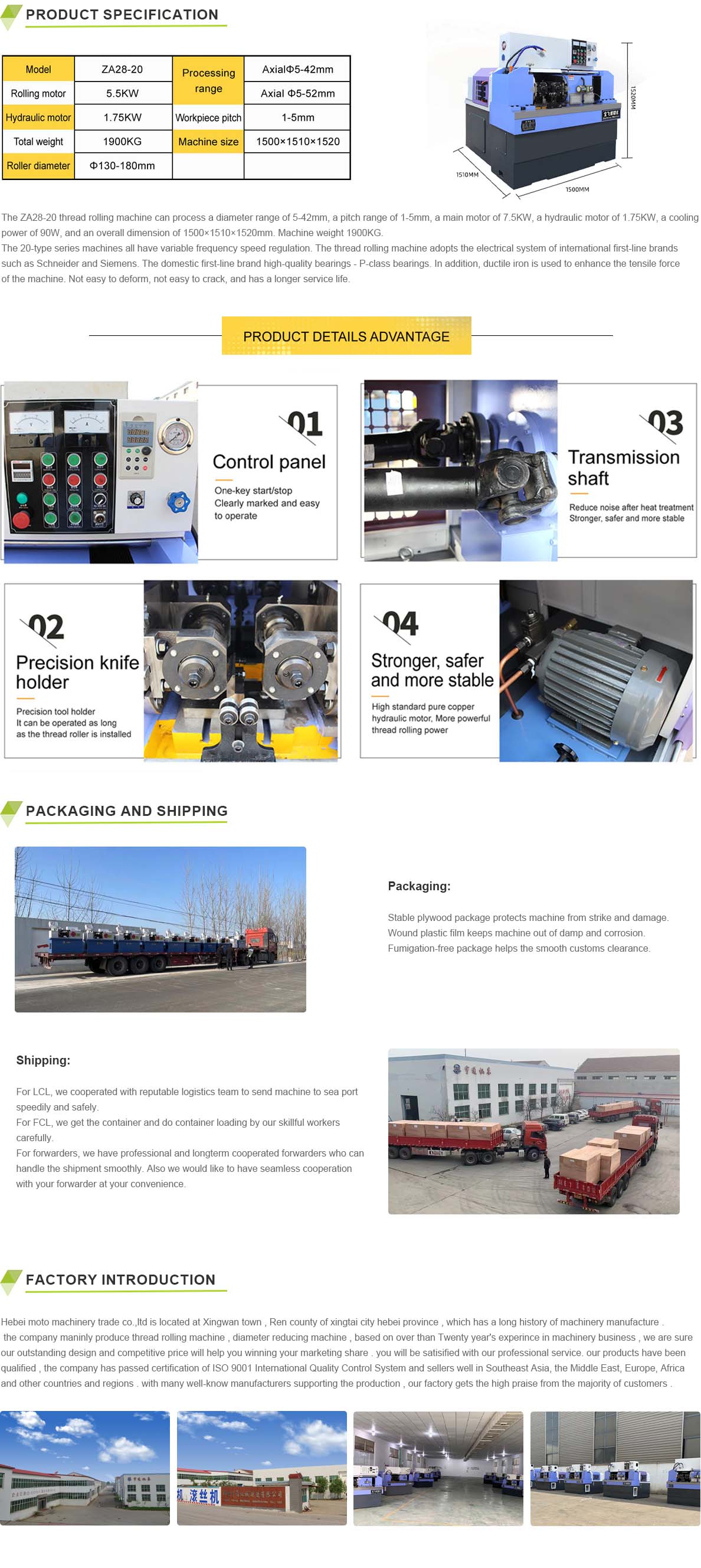

Custom Thread Rolling Machines for OEM Pipe Production with High Precision and Efficiency Solutions

The Importance of OEM Pipe Thread Rolling Machines in Modern Manufacturing

In the world of manufacturing, efficiency and precision are paramount, particularly when it comes to specialized processes like pipe thread rolling. As industries evolve, the demand for Original Equipment Manufacturer (OEM) pipe thread rolling machines has surged, revolutionizing the way threaded pipes are produced. This article explores the significance of these machines and their implications for modern manufacturing.

What is a Pipe Thread Rolling Machine?

A pipe thread rolling machine is a specialized piece of equipment used to create threads on pipes through a process known as rolling. Unlike traditional cutting methods, which remove material to create threads, thread rolling compresses the pipe surface, resulting in stronger threads and less material waste. This process is highly efficient, enabling manufacturers to produce threaded pipes rapidly and with high precision.

The Role of OEMs in Pipe Thread Rolling Machines

OEMs play a crucial role in the production and distribution of pipe thread rolling machines. These manufacturers design the machines to specific client requirements, ensuring that they meet the unique needs of various industries, including oil and gas, construction, and plumbing. OEMs typically focus on quality, durability, and innovation, enabling them to create machines that withstand the rigors of heavy usage and provide longevity to manufacturers.

Advantages of Using OEM Pipe Thread Rolling Machines

1. Precision Engineering OEM machines are built with advanced engineering techniques, ensuring that the threads produced are precise and consistent. This precision reduces the likelihood of defects and rework, ultimately enhancing productivity.

2. Customization One of the standout features of OEM machines is their ability to be customized according to the specific requirements of a manufacturing operation. Customization can include adjustments in size, speed, and thread profiles, allowing businesses to cater to diverse products.

oem pipe thread rolling machine

3. Efficiency and Speed Pipe thread rolling machines designed by OEMs tend to operate at higher speeds compared to traditional threading methods. This improves output and reduces lead times, which is essential in today's fast-paced manufacturing landscape.

4. Cost-Effectiveness While the initial investment in OEM machines may be substantial, the long-term savings accrued from reduced material waste, lower labor costs, and increased productivity often outweigh these upfront costs.

5. Advanced Technology OEMs continuously invest in research and development, which translates into cutting-edge technology in their machines. Innovations such as automated controls, enhanced safety features, and user-friendly interfaces make these machines easier to operate and maintain.

The Future of Pipe Thread Rolling Machines

As industries continue to evolve, the demand for higher efficiency and sustainable practices will shape the future of pipe thread rolling machines. OEMs will likely focus on integrating smart technology, such as IoT connectivity and AI-driven analytics, to enhance machine performance and predictive maintenance capabilities. This evolution will not only optimize production processes but also reduce downtime and operational costs.

Furthermore, with the increasing emphasis on environmental sustainability, OEMs may explore eco-friendly materials and energy-efficient technologies in their machine designs, aligning with global sustainability goals.

Conclusion

OEM pipe thread rolling machines are invaluable assets in modern manufacturing, driving efficiency, precision, and customization in the production of threaded pipes. As technology continues to advance, these machines will play an essential role in shaping the future of multiple industries. Manufacturers that leverage the capabilities of these innovative machines will position themselves favorably in an ever-competitive market, ready to meet the challenges of tomorrow's manufacturing demands.