-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

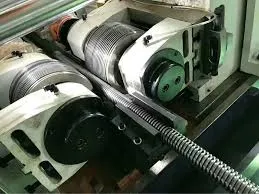

custom scaffolding pipe thread rolling machine

Custom Scaffolding Pipe Thread Rolling Machines Enhancing Efficiency in Construction

In the ever-evolving construction industry, the need for efficiency and precision has never been more critical. Among the myriad of tools designed to facilitate construction processes, custom scaffolding pipe thread rolling machines stand out as essential apparatuses that ensure the seamless manufacturing of threaded scaffolding pipes. These machines not only enhance productivity but also improve the quality and safety of construction projects.

Understanding Thread Rolling Technology

At the heart of a custom scaffolding pipe thread rolling machine is the thread rolling technology, which involves deforming metal to create threads instead of cutting them. This process is generally more efficient than traditional cutting methods. It enhances the physical properties of the material, resulting in stronger threads that can withstand the high stress and load demands typical in construction environments. The method produces threads that are uniform, precise, and free of the imperfections often associated with cutting processes.

Customization Meeting Diverse Needs

One of the standout features of modern thread rolling machines is their capacity for customization. Different construction projects may require a variety of pipe sizes, types, and thread specifications. Custom scaffolding pipe thread rolling machines can be tailored to meet these diverse demands, allowing manufacturers to produce scaffolding pipes that precisely fit project-specific requirements.

For instance, a project may necessitate pipes with specific material properties or distinct thread profiles. The ability to customize not only streamlines the production process but also reduces waste caused by misfits, ultimately leading to cost savings. Such flexibility in manufacturing empowers companies to respond quickly to changing market demands while maintaining high standards of quality.

Increased Productivity and Cost Efficiency

Another significant advantage of custom scaffolding pipe thread rolling machines is the increase in productivity. Traditional methods of pipe threading can be time-consuming and labor-intensive. In contrast, thread rolling machines can operate at high speeds with minimal operator intervention, allowing manufacturers to produce large volumes of threaded pipes in a shorter amount of time.

custom scaffolding pipe thread rolling machine

Moreover, the efficiency gained from using thread rolling technology translates to lower labor costs and increased throughput. Businesses can take on more projects or allocate resources more effectively, boosting their competitive edge in the market.

Ensuring Quality and Safety

Safety is paramount in the construction industry. The integrity of scaffolding systems directly affects the safety of workers at height. Custom scaffolding pipe thread rolling machines are designed to produce consistent and high-quality threads that enhance the reliability of scaffolding structures. By minimizing human error in the threading process and ensuring uniformity, these machines contribute to safer working conditions.

Additionally, advanced threading techniques yield pipes with superior tensile strength, which can withstand greater loads and stresses. This quality assurance fosters confidence in scaffolding installations and mitigates the risks associated with structural failures.

Environmental Considerations

In today's environmentally conscious world, manufacturers are also seeking ways to reduce their carbon footprint. Custom scaffolding pipe thread rolling machines contribute to a greener approach to construction. By minimizing material waste and energy consumption during the manufacturing process, these machines align with sustainable practices. Many modern machines are designed with energy-efficient systems that not only reduce costs but also support eco-friendly initiatives.

Conclusion

Custom scaffolding pipe thread rolling machines represent a significant advancement in construction technology, merging efficiency, customization, and safety. As construction demands continue to grow, the adoption of such innovative machines will play a critical role in helping manufacturers meet project requirements while fostering safer and more sustainable construction practices. Embracing this technology not only enhances productivity but also solidifies a company's reputation for quality and reliability in the competitive construction landscape.