-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

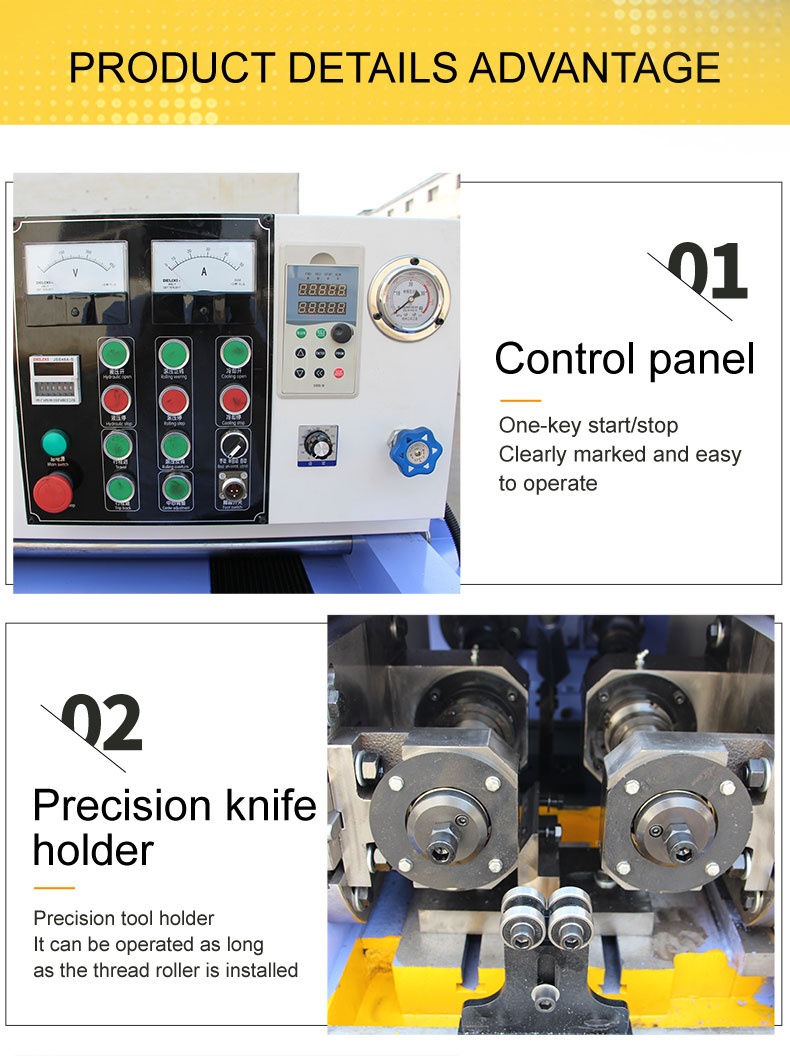

Custom Compact Thread Rolling Equipment for Precision Fastening Solutions

Custom Small Thread Rolling Machines Revolutionizing Precision Manufacturing

In today's rapidly evolving manufacturing landscape, the demand for precision and efficiency has never been greater. Among the crucial technologies that facilitate these demands is the custom small thread rolling machine. These machines have emerged as essential tools for industries ranging from automotive to aerospace, offering superior threading solutions that cater to specific manufacturing needs.

Understanding Thread Rolling Technology

Thread rolling is a cold forming process that involves the creation of external threads on a workpiece by deforming it with a pair of dies. Unlike traditional cutting methods, which remove material and can lead to waste, thread rolling compresses the material, resulting in enhanced material properties. This process not only increases the tensile strength of the threaded parts but also improves their resistance to wear and fatigue.

Custom Solutions for Diverse Applications

What sets custom small thread rolling machines apart is their adaptability to various applications. Standard machines may not meet the unique specifications required by different industries, which is where custom machines come into play. Manufacturers can specify parameters such as thread profile, size, and material type, ensuring that the machine is tailor-made to suit their precise production requirements.

For example, in the aerospace sector, components often require tight tolerances and specialized thread forms to ensure safe and reliable performance. Custom small thread rolling machines enable manufacturers to produce these intricate parts with minimal variability. Similarly, in the automotive industry, where fasteners play a critical role in vehicle assembly, the ability to create custom threads quickly and efficiently is invaluable.

Advantages of Using Custom Small Thread Rolling Machines

1. Enhanced Efficiency These machines are designed for high-speed production, drastically reducing cycle times compared to traditional methods. This efficiency helps manufacturers meet tight deadlines and increases overall output.

custom small thread rolling machine

2. Improved Product Quality Custom machines allow for precise control over the threading process, resulting in higher-quality products with better fit and finish. This level of precision is particularly crucial in sectors where safety and reliability are paramount.

3. Cost-Effectiveness Although the initial investment in a custom machine might be higher, the overall reduction in waste, rework, and increased production rates can lead to significant long-term savings. Additionally, the durability of threads produced through rolling benefits the end product by reducing the risk of failure.

4. Flexibility Custom small thread rolling machines can often be programmed or adjusted to handle a variety of thread sizes and types. This flexibility allows manufacturers to switch between different products with relative ease, adapting to market demands without requiring new equipment.

The Future of Thread Rolling Machines

As technology advances, the future of custom small thread rolling machines looks promising. Innovations such as automation and integration with Industry 4.0 practices are transforming how these machines operate. Equipped with smart sensors and data analytics capabilities, future machines will be able to monitor processes in real time, leading to further improvements in efficiency and quality control.

Moreover, with the growing emphasis on sustainability in manufacturing, thread rolling machines that utilize eco-friendly practices and materials are becoming increasingly popular. As manufacturers strive to reduce their carbon footprint, the move towards more sustainable processes will likely shape the development of future thread rolling technologies.

Conclusion

In conclusion, custom small thread rolling machines represent a significant advancement in precision manufacturing. Their ability to create high-quality, tailored threaded components efficiently makes them indispensable to various industries. As technology continues to progress, these machines will undoubtedly play a crucial role in meeting the demands of modern manufacturing, paving the way for innovation and excellence in production processes.