-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

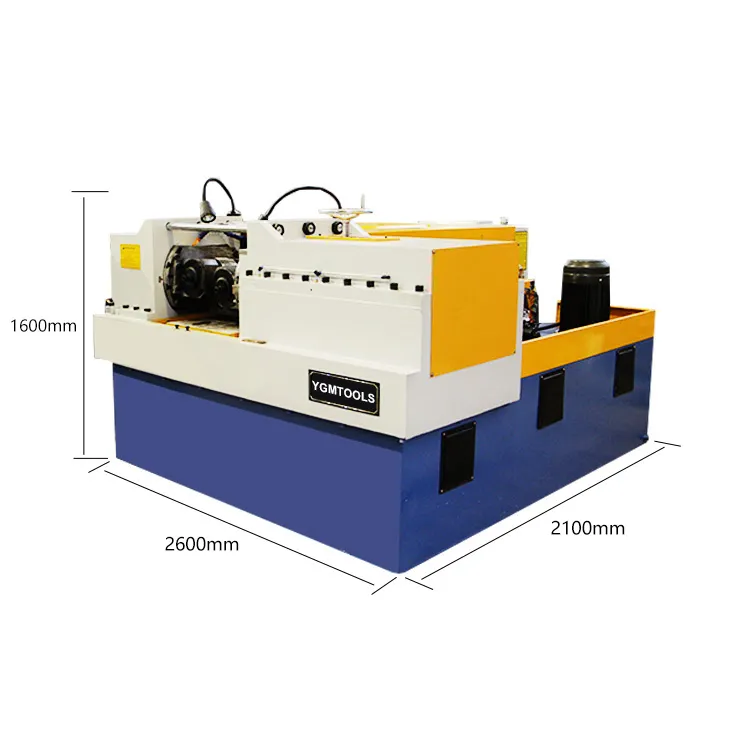

custom small thread rolling machine

Custom Small Thread Rolling Machine Revolutionizing Precision Manufacturing

In today’s fast-paced manufacturing environment, the demand for precision-engineered components is at an all-time high. Industries ranging from automotive to electronics require intricate parts that exhibit strength, reliability, and exact specifications. One of the critical processes that ensure these attributes is thread rolling. Among the various tools used in this process, the custom small thread rolling machine has emerged as a vital asset for manufacturers looking to enhance efficiency and product quality.

Understanding Thread Rolling

Thread rolling is a cold forming process primarily used to produce threads on cylindrical parts. Unlike traditional machining, which removes material to create threads, thread rolling deforms the material through pressure, resulting in threads that are more robust and with tighter tolerances. This method not only improves the mechanical properties of the material—due to the work-hardening effect—but also minimizes waste, making it an environmentally friendly option.

The Role of Custom Small Thread Rolling Machines

Custom small thread rolling machines are designed to cater to specific manufacturing needs. Unlike off-the-shelf machines, custom solutions can be tailored to produce unique thread sizes or styles that meet exacting specifications. This customization is particularly useful for businesses that require intricate thread designs, special pitches, or non-standard materials.

One of the main advantages of using a custom small thread rolling machine is the ability to optimize production processes. Manufacturers can adjust the machine settings to handle various materials, such as steel, aluminum, or plastic, thereby broadening the range of applications. This flexibility allows for rapid prototyping and the adjustment of production lines to meet changing demands, thus ensuring that businesses can remain competitive in an evolving market.

Key Features of Custom Small Thread Rolling Machines

1. Compact Design As the name suggests, small thread rolling machines are designed to save space. Their compact nature makes them ideal for smaller workshops or facilities with limited production floors. Despite their small footprint, these machines deliver high performance and precision.

custom small thread rolling machine

2. High Precision and Repeatability Custom machines are engineered to provide tight tolerances and consistency, essential for maintaining quality control in mass production. The precision of thread rolling contributes significantly to the overall integrity of the finished products.

3. Ease of Use Modern small thread rolling machines often come equipped with user-friendly interfaces and programmable settings. This simplifies the setup process for different thread specifications and allows operators to make adjustments quickly, reducing downtime.

4. Durability and Low Maintenance Built with robust materials and designed to operate under heavy loads, these machines typically require minimal maintenance. This longevity ensures a better return on investment, as companies can rely on consistent performance over time.

5. Energy Efficiency Many manufacturers are focusing on sustainability, and custom small thread rolling machines are no exception. Newer models are designed to consume less energy, which not only lowers operational costs but also minimizes the environmental impact.

Industry Applications

The applications for custom small thread rolling machines are extensive. They are widely used in the production of fasteners, automotive components, machinery parts, and electronic devices. The ability to produce high-quality threads in small batches allows manufacturers to diversify their product offerings, serving niche markets that require unique specifications.

Conclusion

Investing in a custom small thread rolling machine is a strategic move for manufacturers looking to enhance productivity and maintain high-quality standards. By capitalizing on the benefits of thread rolling, such as reduced waste, increased material strength, and design flexibility, businesses can position themselves as leaders in their respective industries. As technology advances further, the capabilities of these machines are likely to expand, paving the way for even more innovative manufacturing solutions. In a world where efficiency and precision are paramount, custom small thread rolling machines stand out as essential tools for success.