-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

custom thread rolling machine

Custom Thread Rolling Machines Precision and Efficiency in Manufacturing

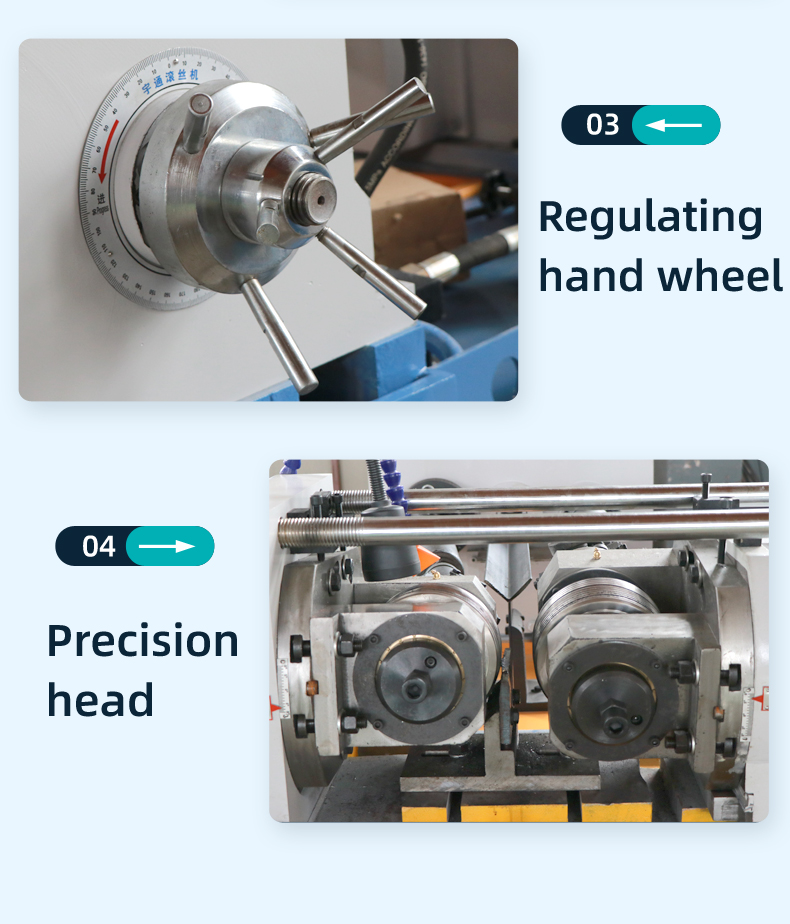

In today's highly competitive manufacturing industry, precision engineering is crucial for producing high-quality threaded components. One of the most effective methods for achieving this precision is through the use of custom thread rolling machines. These specialized machines offer numerous advantages over traditional machining processes, including enhanced efficiency, reduced waste, and improved product consistency.

Thread rolling is a cold forming process where flat or cylindrical metal is shaped into threads by pressing it between two or more moving dies. This technique is widely used for producing fasteners, bolts, and screws, as well as other components requiring high tensile strength and precise dimensions. Custom thread rolling machines are designed to cater to specific manufacturing needs, allowing businesses to optimize their production processes and achieve better results.

One of the key benefits of custom thread rolling machines is their ability to produce threads with exceptional accuracy. Unlike cutting processes that remove material, thread rolling reshapes the metal, resulting in a denser and stronger final product. This not only enhances the performance of the finished components but also minimizes the risk of defects that could arise from machining errors. Moreover, custom machines can be tailored to produce a wide range of thread sizes and types, making them highly versatile for different applications.

custom thread rolling machine

In addition to precision, custom thread rolling machines help to increase production efficiency. The continuous operation of these machines allows for high-speed production runs, significantly reducing cycle times compared to traditional methods. By implementing a custom solution, manufacturers can streamline their workflows, minimize downtime, and ultimately increase their output. This increased efficiency translates to cost savings, enabling businesses to offer competitive pricing without compromising on quality.

Another notable advantage is the reduction of material waste. Traditional machining processes can generate substantial scrap material due to cutting and drilling. In contrast, thread rolling machines utilize the material more effectively, resulting in less waste. This is particularly important in industries where material costs are high and sustainability is a growing concern. By investing in custom thread rolling machinery, companies can not only improve their bottom line but also enhance their environmental responsibility.

Furthermore, custom machines can be equipped with advanced technologies such as computer numerical control (CNC) systems that enable precise programming and automation. This allows for rapid adjustments to production settings, facilitating quick changes in product design or specifications. As a result, businesses can respond more effectively to market demands and customer requirements.

In conclusion, custom thread rolling machines represent a pivotal advancement in manufacturing technology. Their ability to deliver high precision, increased efficiency, reduced waste, and adaptability to various production needs make them an essential asset for any manufacturing facility. As industries continue to evolve and the demand for high-quality threaded components grows, investing in custom thread rolling solutions will undoubtedly pay dividends in terms of quality, productivity, and profitability.