-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

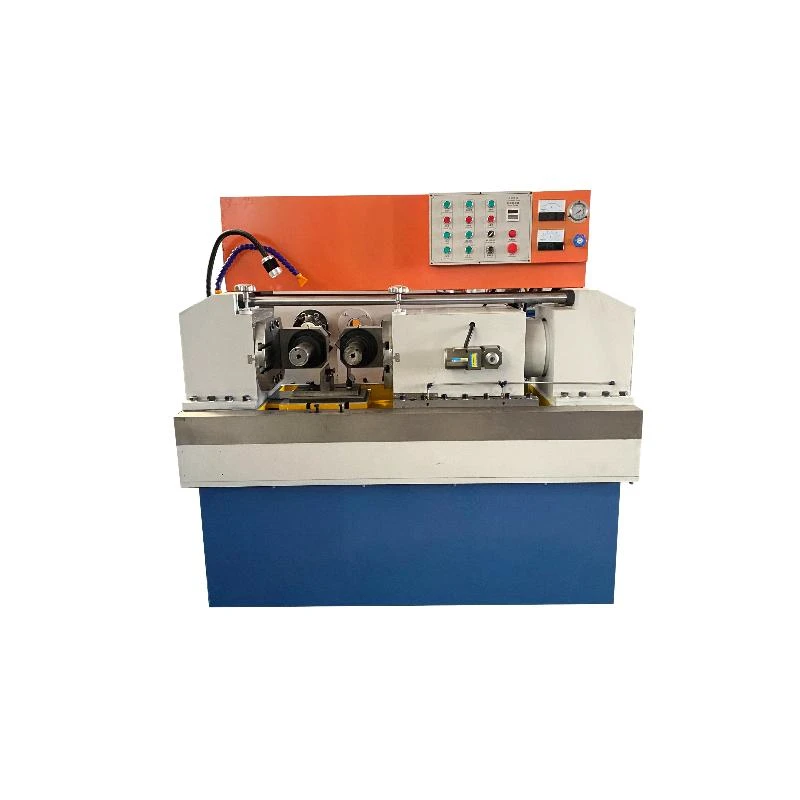

High-Quality Thread Rolling Machines Available for Purchase at Competitive Prices

Custom Thread Rolling Machines for Sale A Comprehensive Guide

In today’s fast-paced manufacturing environment, the efficiency and precision of production processes are paramount. One essential tool that plays a critical role in producing high-quality threaded components is the thread rolling machine. With advancements in technology and the increasing demand for custom solutions, many manufacturers are now turning their attention to custom thread rolling machines tailored to specific needs. This article will explore the importance of these machines, their benefits, and how to choose the right one for your business.

Understanding Thread Rolling Technology

Thread rolling is a cold forming process that creates threads on cylindrical parts by compressing them between two hardened dies. This method is known for its ability to produce high-strength threads with superior surface finishes compared to traditional cutting methods. Thread rolling machines are capable of manufacturing various thread forms, including UN, metric, and specialty threads, making them an indispensable asset in industries such as automotive, aerospace, and construction.

The Benefits of Custom Thread Rolling Machines

1. Tailored Solutions One of the primary advantages of custom thread rolling machines is their ability to meet specific production needs. Every manufacturing process has unique requirements, and customizing a machine allows you to optimize its performance for particular materials, sizes, and thread types. This ensures that you achieve the desired quality and efficiency without compromise.

2. Increased Production Efficiency Custom machines can be designed for rapid setup and quick changeover times, significantly boosting overall production efficiency. With the right configurations, businesses can reduce downtime and increase output, ultimately leading to higher profitability.

3. Enhanced Quality Control A custom thread rolling machine can incorporate specific features that improve quality control measures. This includes advanced monitoring systems that provide real-time feedback on the production process, allowing for immediate adjustments to maintain tolerance levels and ensure consistent quality.

4. Cost-Effectiveness While the initial investment in a custom machine may be higher than standard options, the long-term savings it brings can be substantial. By improving production rates and reducing scrap rates, businesses can lower overall operational costs. Furthermore, custom machines are often more reliable and require less maintenance over time, which can lead to further savings.

custom thread rolling machines for sale

Choosing the Right Custom Thread Rolling Machine

When considering a custom thread rolling machine for your operations, several factors should be taken into account

- Production Volume Assess the expected production volume and choose a machine that can handle your current and future needs. Consider potential scalability as your production demands grow.

- Material Compatibility Ensure that the machine is compatible with the materials you intend to use. Different materials may require distinct rolling processes and machine configurations.

- Thread Specifications Clearly define the types of threads you need to produce, including their size, shape, and tolerance levels. A good manufacturer will work with you to design a machine that accommodates these specifications.

- Technical Support and Maintenance Look for a supplier that offers comprehensive support and maintenance services. A reliable support system can help minimize downtime and ensure the longevity of your machine.

- Budget Considerations Finally, outline your budget. While custom machines typically involve higher upfront costs, consider the long-term return on investment and the potential savings in efficiency and quality.

Conclusion

Investing in a custom thread rolling machine can significantly enhance your manufacturing capabilities, ensuring that you can meet the demands of a competitive market. By understanding the benefits of these machines and carefully choosing the right one for your needs, you can streamline your production processes while consistently delivering high-quality threaded components. As industries continue to evolve, having the right equipment can set your business apart from the competition. Whether you need a single machine or an entire production line, exploring custom solutions could be the key to unlocking your business's full potential.