-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

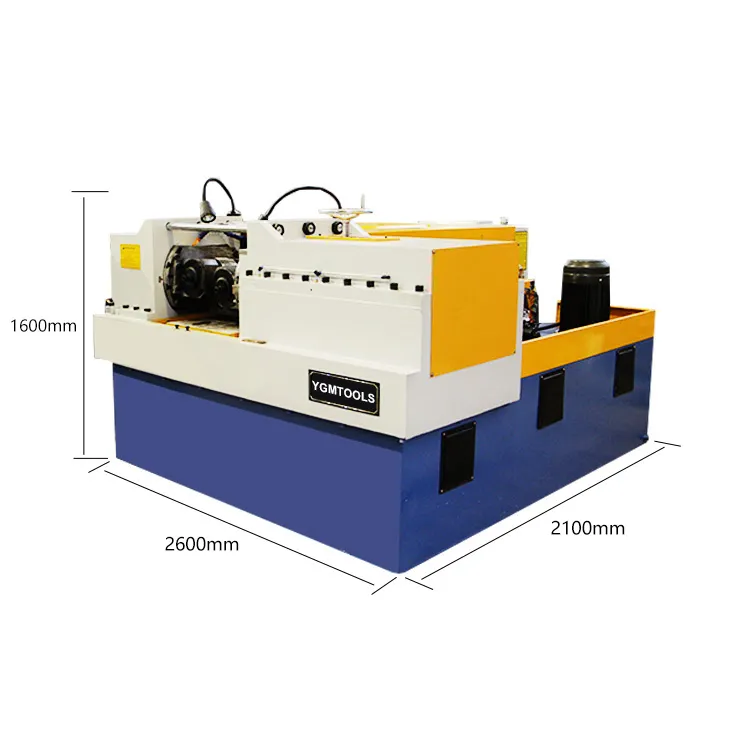

custom wire thread rolling machine

Custom Wire Thread Rolling Machines An Overview

In the modern manufacturing landscape, precision and efficiency are paramount. One of the standout technologies that have evolved to meet these demands is the custom wire thread rolling machine. These machines have become essential in various industries, providing the ability to create high-quality threaded components efficiently and accurately.

What is Thread Rolling?

Before delving into the specifics of custom machines, it's important to understand the thread rolling process. Thread rolling is a cold-forming process that creates threads on the surface of a workpiece by deforming the material rather than removing it. This method has several advantages over traditional machining methods, including better material utilization, increased strength of the finished threads, and a smoother surface finish.

The process involves rotating two dies that exert pressure on the wire as it is passed through. This rolling action displaces the material and forms the desired thread profile. The result is a product that is not only stronger due to the work-hardening effects of the process but also generally more cost-effective to produce.

The Importance of Customization

While many standard thread rolling machines exist, the need for customization has led to the development of bespoke solutions tailored to specific client requirements

. Custom wire thread rolling machines can accommodate various types of materials, thread profiles, and sizes, making them versatile tools for manufacturers.Custom machines are designed to meet specific production requirements, which can include adjusting speeds, loads, and operational parameters based on the unique needs of each application. This level of customization unlocks a new realm of possibilities for manufacturers, allowing them to optimize their production processes, reduce waste, and improve overall throughput.

Advantages of Custom Wire Thread Rolling Machines

1. Increased Precision and Quality Tailored machines can incorporate the latest technologies and features such as advanced sensors and software-controlled systems. This ensures that every component meets stringent quality requirements and tolerances.

custom wire thread rolling machine

2. Enhanced Production Efficiency Customized machines can be optimized for speed and efficiency, reducing cycle times and increasing overall output. They can be programmed to handle multiple tasks, which minimizes downtime and enhances productivity.

3. Flexibility for Diverse Applications Industries such as automotive, aerospace, medical, and construction all require various threaded components. Custom machines can be designed to work with different materials and thread designs, ranging from fine to coarse threads.

4. Cost Effectiveness While custom machines may have a higher initial investment, the long-term cost benefits through improved efficiency, reduced waste, and lower labor costs can significantly outweigh the upfront expenses.

5. Simplified Maintenance and Support Custom machines can be built with user-friendly interfaces and modular designs, making maintenance easier. Additionally, manufacturers often provide ongoing support and training tailored to the customer’s specific machine configuration.

Key Considerations for Custom Machines

When investing in a custom wire thread rolling machine, there are several factors to consider

- Material Compatibility Ensure that the machine can handle the types of materials you will be working with. - Thread Specifications Clearly define the thread profiles you need and make sure the machine is capable of producing these efficiently. - Volume Requirements Consider the anticipated production volume and ensure the machine can scale accordingly. - Future Expansion Think about your future needs; a machine that can adapt to new requirements can save significant costs in the long run.

Conclusion

Custom wire thread rolling machines represent a vital investment for manufacturers looking to stay competitive in today’s fast-paced market. By leveraging the advantages of precision engineering and tailored solutions, companies can enhance their production capabilities, improve product quality, and reduce operational costs. As industries continue to evolve, the demand for customizable machinery will only grow, underscoring the importance of innovation in manufacturing processes. In a world where efficiency meets specificity, custom wire thread rolling machines stand out as indispensable tools for success.