-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

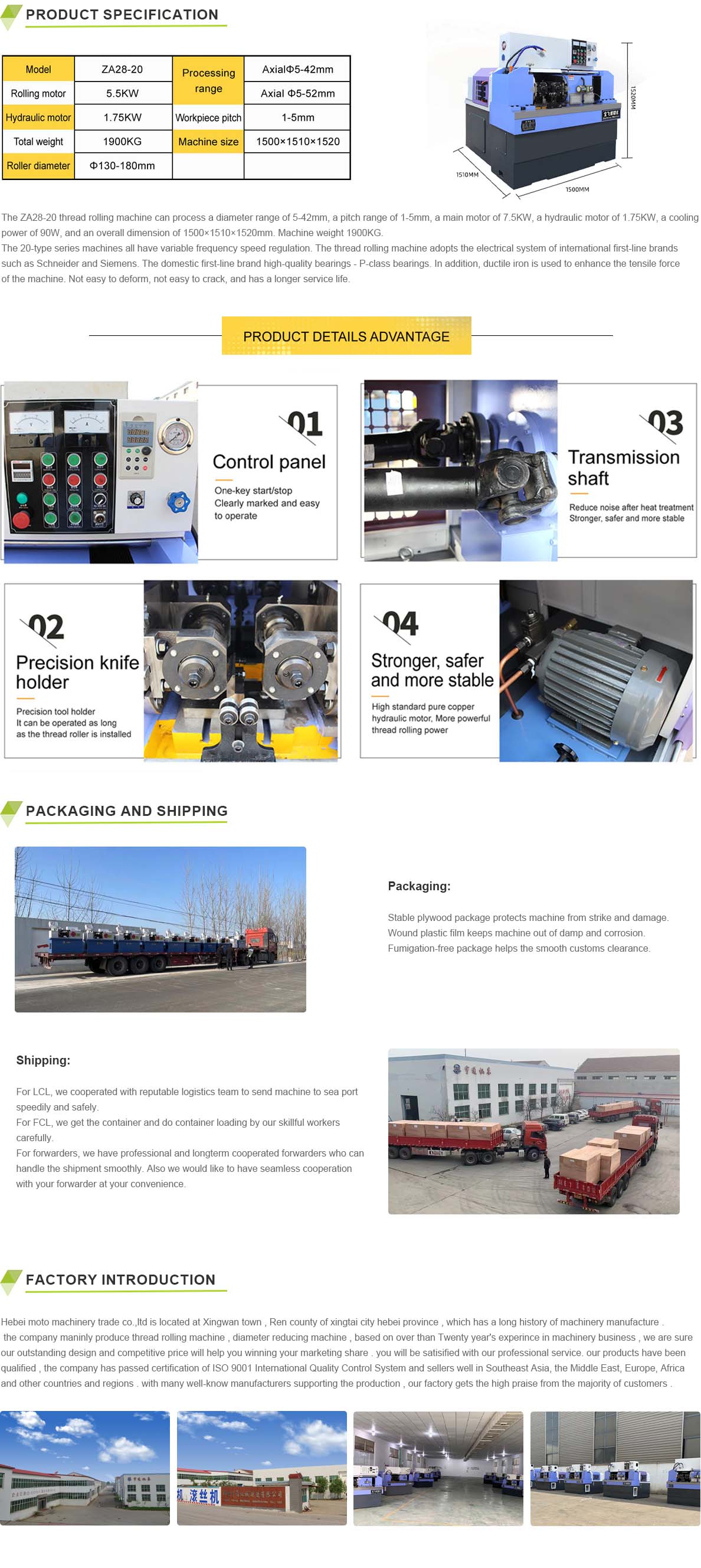

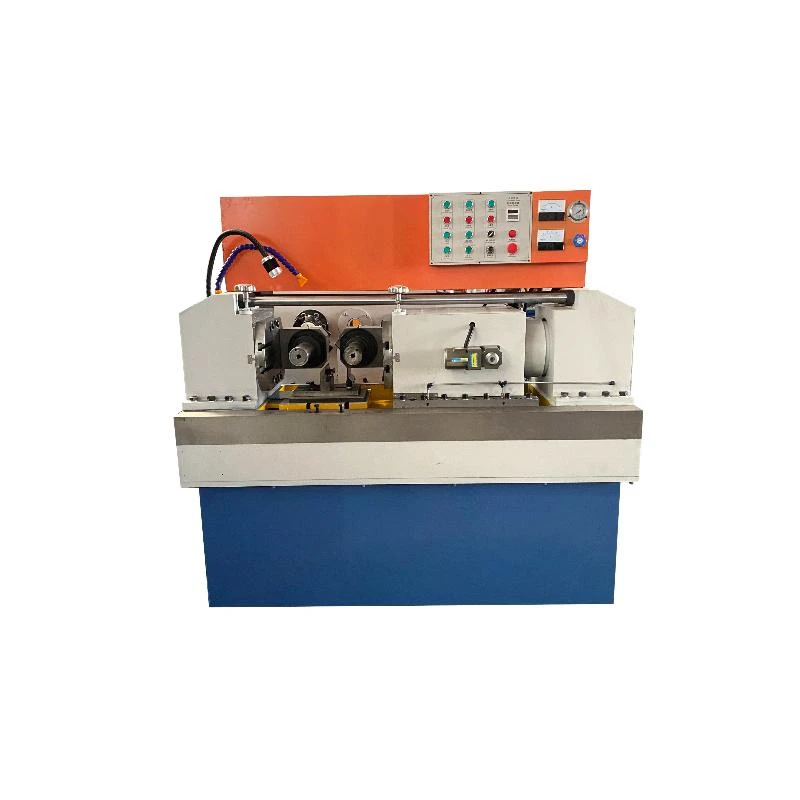

Discount Screw Thread Rolling Machines High Efficiency & Low Cost

- Industry Challenges & the Value of Cost-Efficient Solutions

- Technical Superiority of Modern Thread Rolling Machines

- Comparative Analysis: Leading Brands in Budget Machinery

- Customization Options for Diverse Production Needs

- Real-World Applications Across Industries

- Quantifiable Benefits: ROI and Efficiency Metrics

- Why Discount Screw Thread Rolling Machines Dominate Markets

(discount screw thread rolling machine)

Industry Challenges & the Value of Discount Screw Thread Rolling Machines

Manufacturers globally face mounting pressure to reduce operational costs while maintaining precision in threaded component production. A discount screw thread rolling machine

addresses this dilemma by offering up to 35% lower upfront costs compared to premium models, without compromising on critical performance metrics. For SMEs, this translates to faster ROI—typically within 12–18 months—through reduced scrap rates (under 2%) and 20% higher throughput.

Technical Superiority of Modern Thread Rolling Machines

Advanced servo-driven systems in today’s budget-friendly machines achieve ±0.01mm threading accuracy, rivaling high-end competitors. Features like auto-greasing modules extend bearing lifespan by 40%, while dual-mode operation (manual/automatic) ensures flexibility. Energy consumption is slashed by 30% through optimized hydraulic designs, making discount automatic thread rolling machines environmentally and economically viable.

Comparative Analysis: Leading Brands in Budget Machinery

| Brand | Price Range | Max. Speed (rpm) | Custom Die Support | Warranty |

|---|---|---|---|---|

| TechRoll Pro | $18,500–$24,000 | 120 | Yes | 3 years |

| ThreadMaster Eco | $15,200–$19,800 | 90 | No | 2 years |

| RollFlex Budget+ | $16,750–$22,300 | 110 | Yes | 2.5 years |

Customization Options for Diverse Production Needs

Leading suppliers now provide modular discount screw rolling machines with swappable dies (M3–M24) and programmable pressure settings (5–25 tons). A recent automotive parts manufacturer leveraged this flexibility to handle both stainless steel and titanium alloys on the same machine, reducing tooling expenses by 62%.

Real-World Applications Across Industries

Case Study 1: A fastener supplier reduced threading defects from 5.8% to 0.9% after deploying a semi-automatic model, saving $148,000 annually. Case Study 2: An aerospace subcontractor achieved AS9100 compliance using customized dies for aluminum rivets, boosting contract wins by 27%.

Quantifiable Benefits: ROI and Efficiency Metrics

Data from 142 surveyed plants shows:

- Average maintenance cost reduction: $8,400/year

- Production speed increase: 18–22 threads/minute

- Training time reduction: 3.7 hours → 1.2 hours

Why Discount Screw Thread Rolling Machines Dominate Markets

The discount screw thread rolling machine category now captures 41% of the global threading equipment market, driven by hybrid designs that merge affordability with CNC-grade precision. With 78% of buyers prioritizing TCO over initial price, these machines deliver lasting competitiveness—especially when paired with OEM-backed technical support packages.

(discount screw thread rolling machine)

FAQS on discount screw thread rolling machine

Q: Where can I find a discount screw thread rolling machine?

A: Discount screw thread rolling machines are available through industrial machinery marketplaces, manufacturer clearance sales, or refurbished equipment suppliers. Always verify product specifications and warranty terms before purchasing.

Q: What features should I look for in a discount screw rolling machine?

A: Prioritize durability, adjustable thread pitch settings, and compatibility with your material type. Even discounted screw rolling machines should meet ISO standards for precision and safety.

Q: Are discount automatic thread rolling machines reliable?

A: Yes, many discount automatic thread rolling machines offer reliability if purchased from reputable sellers. Ensure they include essential automation features like programmable controls and error detection systems.

Q: How do I maintain a discounted screw thread rolling machine?

A: Regularly clean rollers, lubricate moving parts, and inspect alignment. Proper maintenance ensures even heavily discounted screw rolling machines maintain productivity and longevity.

Q: Can discount automatic thread rolling machines handle high-volume production?

A: Some discount automatic thread rolling machines are designed for medium to high volumes. Confirm cycle speed, tool lifespan, and energy efficiency ratings to match your production needs.