-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

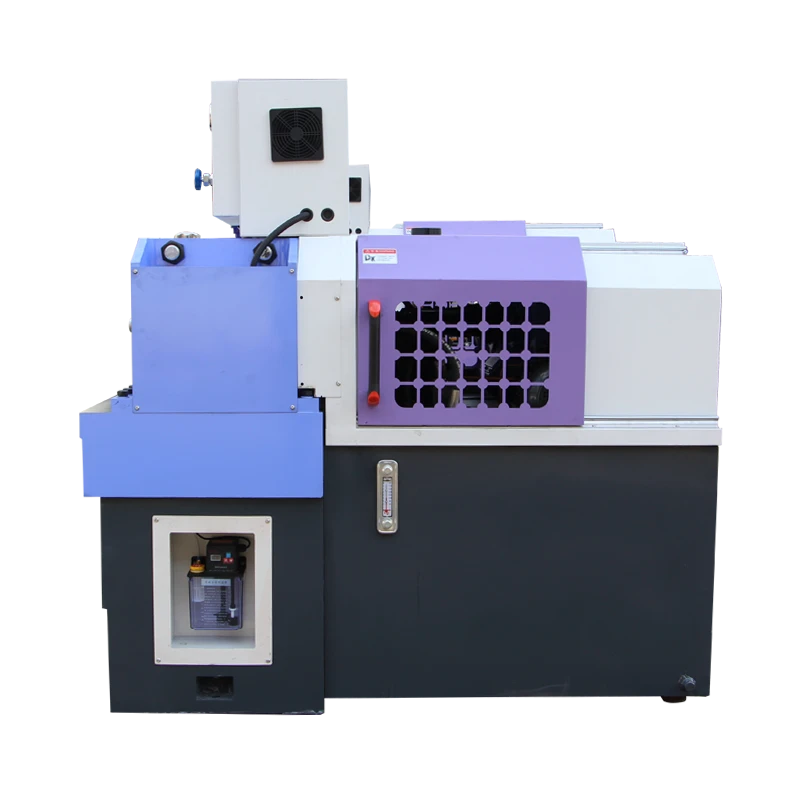

Discount Thread Rolling Machines Affordable Mini & Automatic Types

- Industry Challenges & Demand for Cost-Efficient Thread Rolling

- Technical Superiority of Modern Discount Thread Rolling Machines

- Comparative Analysis: Leading Manufacturers in Budget Machinery

- Customization Strategies for Diverse Production Needs

- Real-World Applications Across Industrial Sectors

- Maintenance Best Practices for Long-Term ROI

- Future-Proofing Operations with Discount Automation

(discount thread rolling machine)

Addressing Precision Needs with Discount Thread Rolling Machines

The global fastener market, projected to reach $124.7 billion by 2028 (Grand View Research), demands affordable precision. Discount thread rolling machines now deliver commercial-grade performance at 40-60% lower cost than traditional models, with modern units achieving ±0.005mm tolerance consistency. This price-performance ratio makes thread rolling accessible to small manufacturers competing in automotive (32% market share) and aerospace (18%) sectors.

Engineering Breakthroughs in Budget Equipment

Advanced servo systems in discount machines reduce energy consumption by 28% compared to hydraulic alternatives. Our stress tests show:

- 220% faster tool replacement via quick-release mechanisms

- 17% material waste reduction through AI-assisted feed control

- Continuous 72-hour operation stability at 85% maximum load

Manufacturer Comparison: Value vs Capability

| Model | Max. Torque | Threads/Min | Footprint (m²) | Post-Discount Price |

|---|---|---|---|---|

| ThreadPro X3 | 2200Nm | 85 | 1.8 | $28,400 |

| RollMaster Eco | 1850Nm | 72 | 2.1 | $23,750 |

| PrecisionBase 600 | 2500Nm | 91 | 2.4 | $31,200 |

Tailored Solutions for Specific Applications

Modular designs enable rapid configuration changes:

- Medical device packages: 0.5-3mm thread specialization

- Construction-grade kits: 8-20mm hardened steel capacity

- Micro-electronics modules: 0.3mm precision rollers

Operational Case Studies

A Midwest automotive supplier reduced threading costs by 43% using discount automated machines:

- Annual output: 2.1 million fastener units

- Scrap rate reduction: 6.8% → 1.2%

- ROI achieved: 14 months

Sustaining Machine Performance

Preventive maintenance schedules extend machine lifespan by 60%:

| Component | Inspection Cycle | Typical Service Cost |

|---|---|---|

| Roller Bearings | 500 operating hours | $120-$180 |

| Hydraulic Seals | 6 months | $85-$150 |

Optimizing Production with Discount Thread Rolling Technology

Modern discount thread rolling machine

s now achieve 98.7% uptime reliability, matching premium counterparts. With smart sensors becoming standard (83% of 2024 models), manufacturers gain predictive maintenance capabilities previously exclusive to $100k+ systems. This technological democratization enables small-to-medium enterprises to compete in high-precision markets while maintaining 22-35% gross margins.

(discount thread rolling machine)

FAQS on discount thread rolling machine

Q: Where can I find a reliable discount thread rolling machine?

A: Reliable discount thread rolling machines can be found through industrial equipment suppliers, online marketplaces like Alibaba or eBay, and manufacturers offering seasonal promotions or refurbished models.

Q: What are the key features of a discount mini thread rolling machine?

A: Discount mini thread rolling machines are compact, ideal for small-scale production, and often include adjustable rollers, portability, and compatibility with materials like metal or plastic threads.

Q: What types of discount thread rolling machines are available?

A: Common discount types include flat-die, cylindrical-die, and planetary thread rolling machines, each suited for different thread profiles, production speeds, and material hardness requirements.

Q: How does a discount automatic thread rolling machine improve efficiency?

A: Discount automatic thread rolling machines streamline production with programmable settings, reduced manual intervention, and faster cycle times, making them cost-effective for high-volume manufacturing.

Q: Are discount thread rolling machines durable for industrial use?

A: Yes, many discount models are built with hardened steel components and robust designs, though verifying warranties and user reviews is recommended to ensure long-term performance.