-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

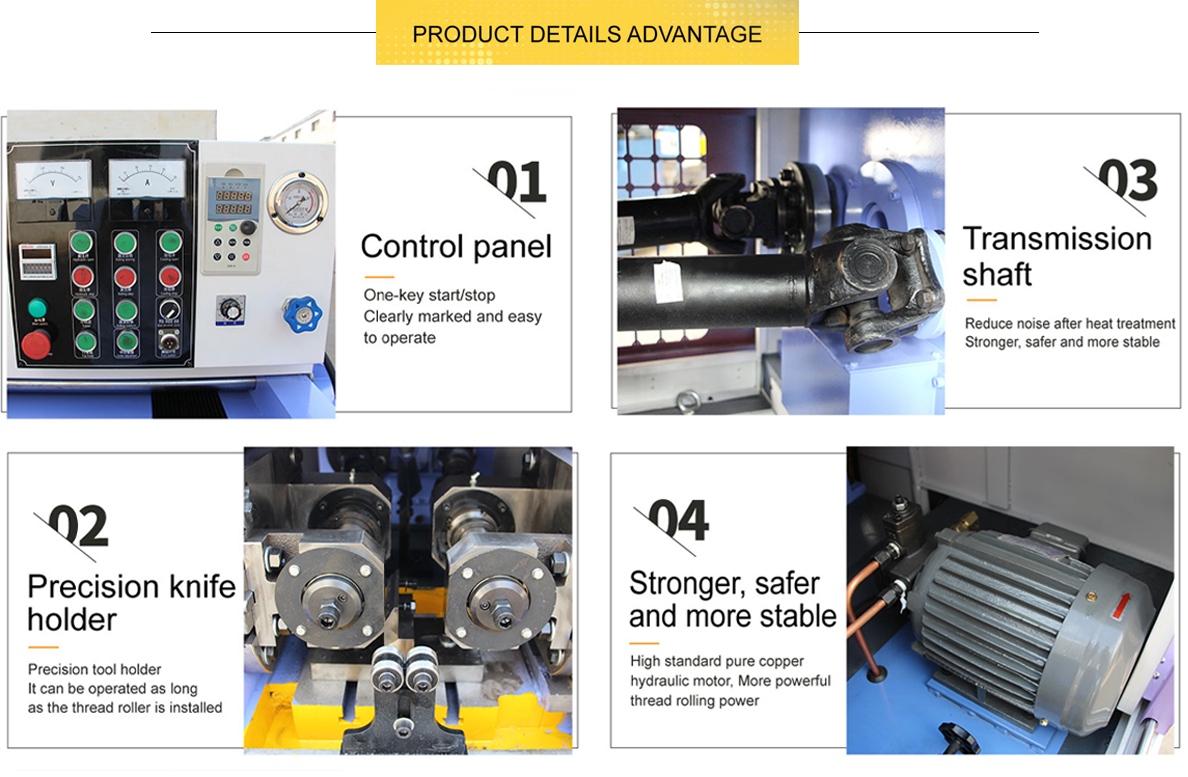

Affordable Nail Thread Rolling Machines with Exciting Discounts Available Now

Understanding Discount Nail Thread Rolling Machines

In the competitive landscape of manufacturing and production, the importance of efficient machinery cannot be overstated. One such machine that plays a crucial role in the manufacturing of nails and fasteners is the nail thread rolling machine. With the rising demand for various metal fasteners across industries, the significance of these machines has surged, and many manufacturers are looking for ways to acquire them at a reduced cost. This is where discount nail thread rolling machines come into play.

What is a Nail Thread Rolling Machine?

A nail thread rolling machine is a specialized piece of equipment designed to create threads on metal rods, which are subsequently cut to length to form nails and other fasteners. The process of thread rolling is an innovative cold-forming technique where the material is deformed to achieve the desired thread profile without removing any material. This process not only enhances the mechanical properties of the fasteners but also prevents wastage, making it an eco-friendly option in the manufacturing of nails.

Benefits of Using Nail Thread Rolling Machines

1. Efficiency Nail thread rolling machines are known for their high-speed operations, which significantly boost production rates. Unlike traditional methods that may involve cutting and machining, thread rolling processes can produce more parts in less time.

2. Quality The threads produced by these machines are often stronger and more durable than those made by cutting methods due to the work-hardening effect imparted during the rolling process. This means that the fasteners not only meet but often exceed industry standards for performance and reliability.

3. Cost-Effectiveness The ability to create products with minimal waste makes thread rolling machines an economical choice for manufacturers. Although the initial investment may be substantial, the long-term savings in raw materials and time can be significant.

4. Versatility Modern nail thread rolling machines can be adjusted to produce a wide variety of thread sizes and configurations. This adaptability makes them ideal for manufacturers who may need to switch between different products frequently.

The Appeal of Discount Nail Thread Rolling Machines

discount nail thread rolling machine

With all these advantages, it's no surprise that manufacturers are eager to invest in nail thread rolling machines. However, the cost can be a barrier for smaller companies or startups. This is where discount nail thread rolling machines become an attractive option.

Discounted machines can often be found through various channels

1. Used Machinery Markets Many reputable dealers specialize in selling pre-owned manufacturing equipment at reduced prices. These machines may have been well-maintained and can offer the same efficiency and reliability as new ones.

2. Manufacturer Promotions Some manufacturers may offer seasonal discounts or trade-in deals, allowing businesses to acquire new machines at lower costs.

3. Online Platforms E-commerce websites cater to industrial machinery and often feature competitive pricing. Bargain hunting can lead to substantial savings.

4. Trade Shows and Expos Attending industry trade shows can provide opportunities to purchase machines at discounted rates, often with incentives such as warranties or service agreements.

When considering a discounted nail thread rolling machine, it is essential to conduct thorough research. Potential buyers should evaluate the machine's condition, compatibility with existing operations, and the availability of parts and service support.

Conclusion

Nail thread rolling machines are fundamental in producing high-quality fasteners, catering to the growing demands of various industries. With the option of acquiring these machines at discounted rates, even smaller manufacturers can enhance their production capabilities without overspending. Investing in a nail thread rolling machine—whether new or used—can significantly improve operational efficiency, product quality, and ultimately, profitability. As technology continues to evolve, the availability of advanced machinery will only improve, making it an exciting time for manufacturers looking to invest in their future.