-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

discount thread rolling machine setup

Optimizing Setup for Discount Thread Rolling Machines

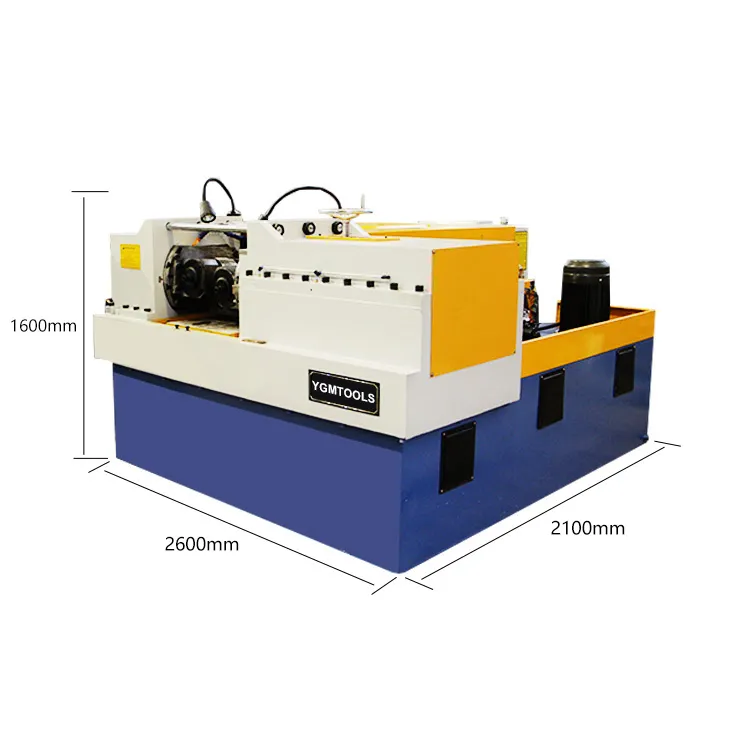

In the modern manufacturing landscape, efficiency and cost-effectiveness are paramount. As companies seek to maximize their production capabilities while minimizing expenses, discount thread rolling machines have emerged as a viable solution. These machines, known for their ability to transform raw materials into high-quality threaded components, can significantly enhance production rates when properly set up.

The setup process of a thread rolling machine is crucial to ensuring optimal functionality and production output. A well-configured machine can lead to decreased waste and improved product quality, which are essential for gaining a competitive edge in today’s market. To achieve this, manufacturers should adhere to several best practices when setting up their thread rolling machines.

Firstly, it's important to select the right rolling dies. The compatibility between the dies and the material being processed directly impacts the quality of the threads produced. Discount thread rolling machines often come with a variety of dies that cater to different materials and thread specifications. Therefore, manufacturers should conduct thorough research and select dies that match their specific production needs.

discount thread rolling machine setup

Next, machine calibration is vital. Adjusting the machine settings to accommodate the specific dimensions and tolerances of the desired threads ensures consistency. Utilizing digital gauges and tools can aid in achieving precise measurements during the calibration process. Regularly scheduled maintenance and recalibration can help prolong the life of the machine and maintain its accuracy.

Moreover, operator training cannot be overlooked. Ensuring that all personnel involved in the operation of the thread rolling machine are well-trained enhances productivity and safety. Operators should be familiar with the machine's capabilities, as well as the best practices for setup and operation, to minimize errors that could lead to costly downtime or defective products.

Lastly, implementing a quality control program during the setup phase can significantly benefit manufacturers utilizing discount thread rolling machines. Regular inspections of produced components against specified standards help identify any deviations early in the process, allowing for timely adjustments and improvements.

In conclusion, the successful setup of discount thread rolling machines is essential for maximizing production efficiency and quality. By selecting appropriate dies, calibrating the machine accurately, investing in thorough operator training, and maintaining rigorous quality control, manufacturers can enhance their operational capabilities and achieve a better return on investment. Embracing these strategies will ultimately position companies for success in a competitive marketplace.