-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 03:22

Back to list

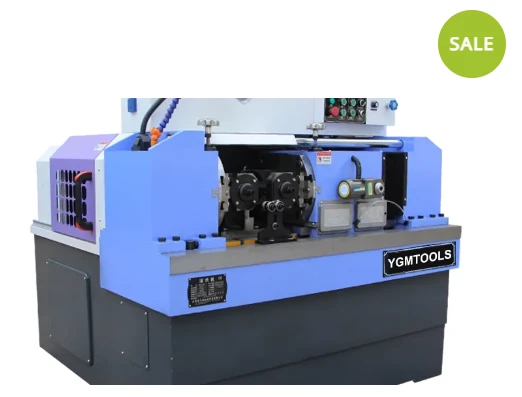

discount types of thread rolling

In the realm of manufacturing and precision engineering, thread rolling stands as a pivotal process, delivering exceptional results by creating superior threads for various applications. Unlike cutting processes, thread rolling involves forming threads using a die, offering significant advantages not just in quality but also in cost-efficiency. However, as manufacturers seek to optimize expenses without compromising on quality, understanding the discount types of thread rolling becomes paramount.

Environmentally-driven discounts have also emerged as a compelling incentive. Manufacturers prioritizing eco-friendly practices and choosing sustainable materials can avail themselves of rebates tailored to support green initiatives. This alignment not only reduces carbon footprints but also enhances a company’s reputation among environmentally-conscious consumers. Incorporating technological advancements into the thread rolling process can also lead to substantial discounts. Automation and state-of-the-art machinery, though initially a high investment, dramatically cut down maintenance and labor costs in the long run. Service providers often offer discounts or flexible financing options for companies willing to upgrade their technology stack, ensuring both parties remain competitive in a rapidly evolving market. Additionally, early payment discounts serve as another strategic financial lever. Providers may offer reduced rates to incentivize prompt payments, thereby improving their cash flow management. For manufacturers, this means an opportunity to lower operational expenditure and potentially increase profit margins. In navigating the landscape of thread rolling discounts, manufacturers must wield expertise and a strategic approach. It’s crucial to assess the compatibility of these discounts with business objectives, ensuring that quality and production capacity are not compromised. Leveraging such discounts requires a keen understanding of market dynamics, provider capabilities, and emerging industry trends. Establishing a dialogue with thread rolling providers, grounded in trust and transparency, facilitates the identification of mutual benefits and the crafting of bespoke discount arrangements. This relationship, founded on knowledge and communication, remains instrumental in driving both cost efficiency and product excellence. As industries forge ahead, the ability to strategically exploit discount types within thread rolling not only fortifies a company’s competitive edge but also paves the way for innovative manufacturing solutions that align with future-ready strategies and consumer demand.

Environmentally-driven discounts have also emerged as a compelling incentive. Manufacturers prioritizing eco-friendly practices and choosing sustainable materials can avail themselves of rebates tailored to support green initiatives. This alignment not only reduces carbon footprints but also enhances a company’s reputation among environmentally-conscious consumers. Incorporating technological advancements into the thread rolling process can also lead to substantial discounts. Automation and state-of-the-art machinery, though initially a high investment, dramatically cut down maintenance and labor costs in the long run. Service providers often offer discounts or flexible financing options for companies willing to upgrade their technology stack, ensuring both parties remain competitive in a rapidly evolving market. Additionally, early payment discounts serve as another strategic financial lever. Providers may offer reduced rates to incentivize prompt payments, thereby improving their cash flow management. For manufacturers, this means an opportunity to lower operational expenditure and potentially increase profit margins. In navigating the landscape of thread rolling discounts, manufacturers must wield expertise and a strategic approach. It’s crucial to assess the compatibility of these discounts with business objectives, ensuring that quality and production capacity are not compromised. Leveraging such discounts requires a keen understanding of market dynamics, provider capabilities, and emerging industry trends. Establishing a dialogue with thread rolling providers, grounded in trust and transparency, facilitates the identification of mutual benefits and the crafting of bespoke discount arrangements. This relationship, founded on knowledge and communication, remains instrumental in driving both cost efficiency and product excellence. As industries forge ahead, the ability to strategically exploit discount types within thread rolling not only fortifies a company’s competitive edge but also paves the way for innovative manufacturing solutions that align with future-ready strategies and consumer demand.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025